External pressure resistant cabin structure and preparation method thereof

A ballast and shell technology, which is applied to underwater operation equipment, special-purpose ships, ships, etc., can solve the problems of low pressure resistance, low safety performance of the cabin, large weight and buoyancy, and achieve strong external pressure resistance. , excellent sealing effect, high buoyancy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below the attached figures in the embodiments of the present invention will be clearly and fully described to the technical solutions in the embodiments of the present invention.

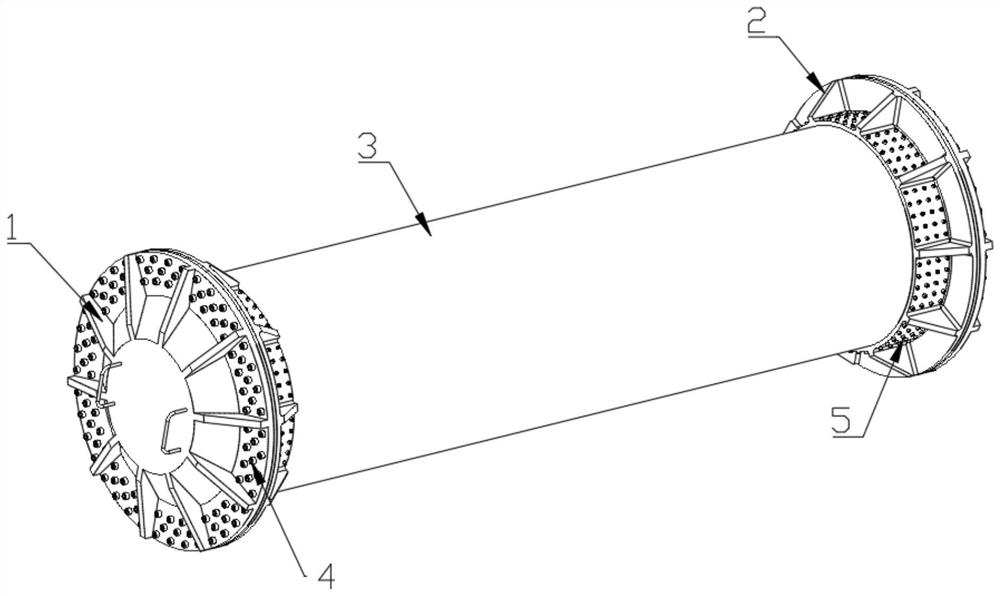

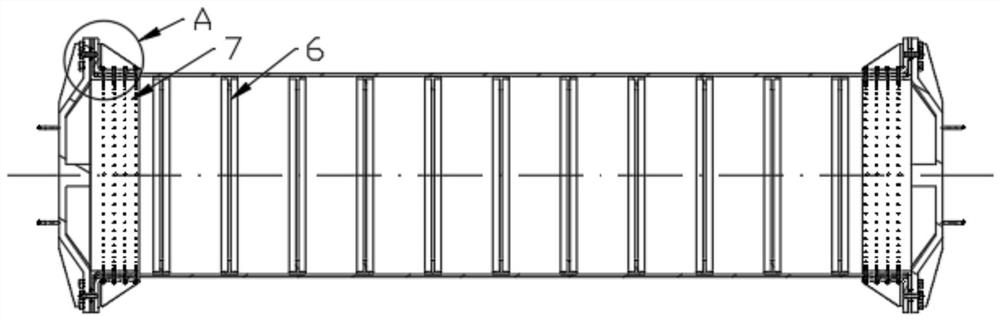

[0038] See Figure 1-5 , The present invention provides a technical solution:

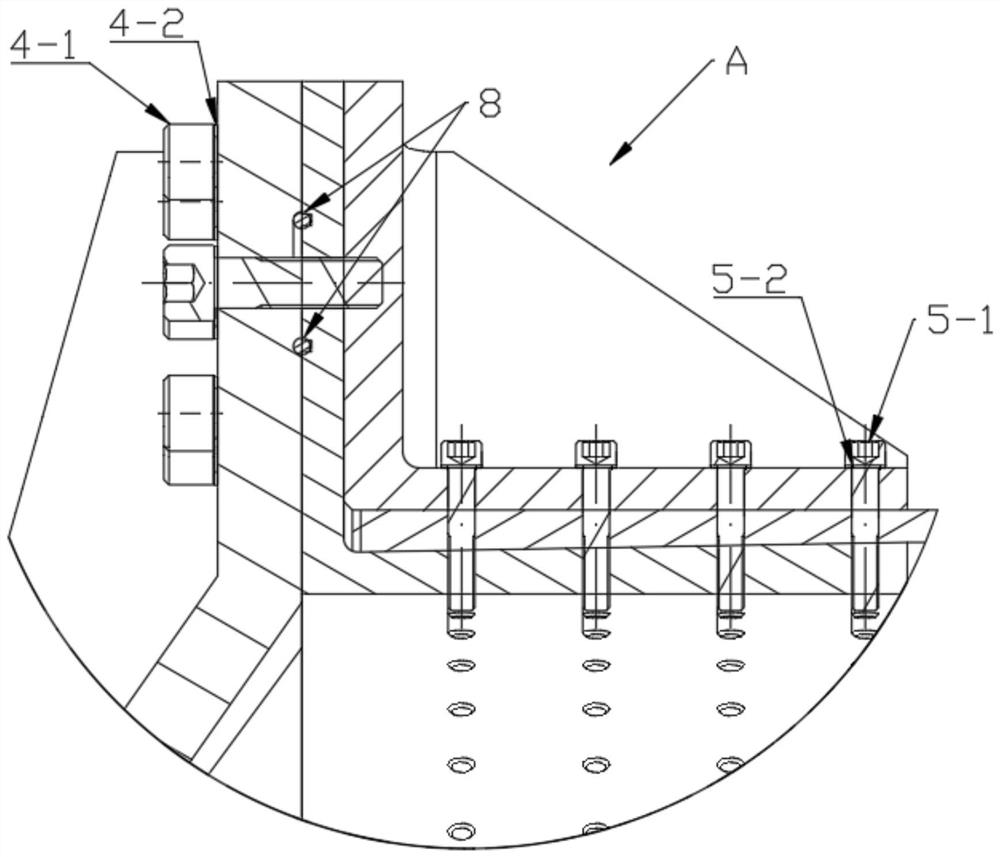

[0039] A structured structure, including shell 3, and round -headed surfaces on both sides of the shell 3 through the connect fastener 5 with the outer joint 2 and the inner connector 7, and the one end of the outer joint 2 through the blocking fastener 4 There are two sealing circles 8 with a fixed connection with a blocking cover 1 and the outer connector 2, one end of the inner joint 7, and the sealing ring 8 is closely fitted with the shell 3 and the blocking cover 1, respectively. Circle tendon 6; at work, fix it through fastening and blocking fastener 4 pairs of shells 3, outer joint 2, inner connector 7, and blocking cover 1 to achieve the effect of easy disassembly; the sealing ring set is set by settings; 8, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com