Environment protection artificial chamois and its preparation method

A technology of artificial suede and a manufacturing method, applied in textiles and papermaking, etc., can solve the problems of poor wear resistance and poor physical properties of artificial suede, and achieve the effect of increasing strength and physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

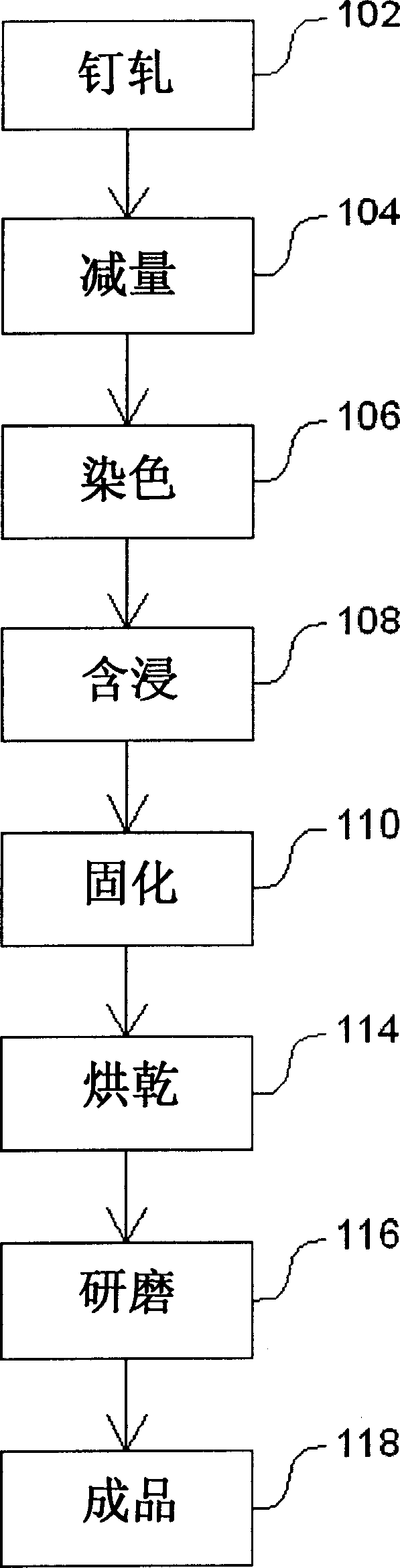

Method used

Image

Examples

Embodiment 1

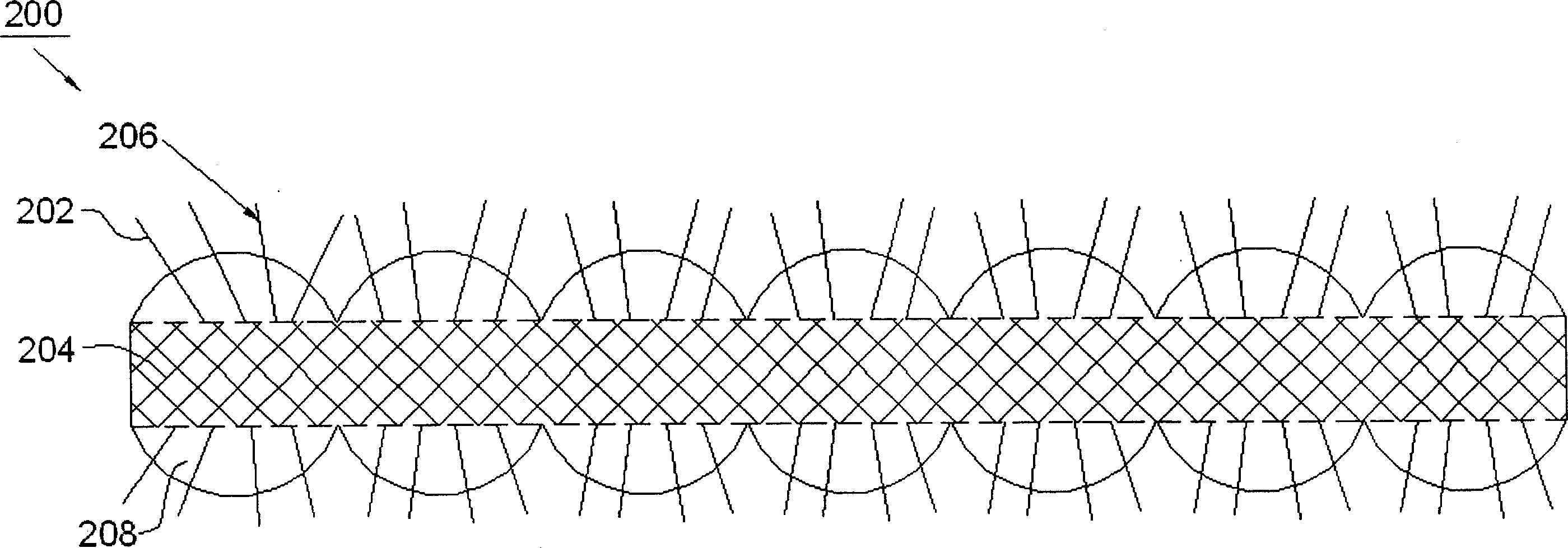

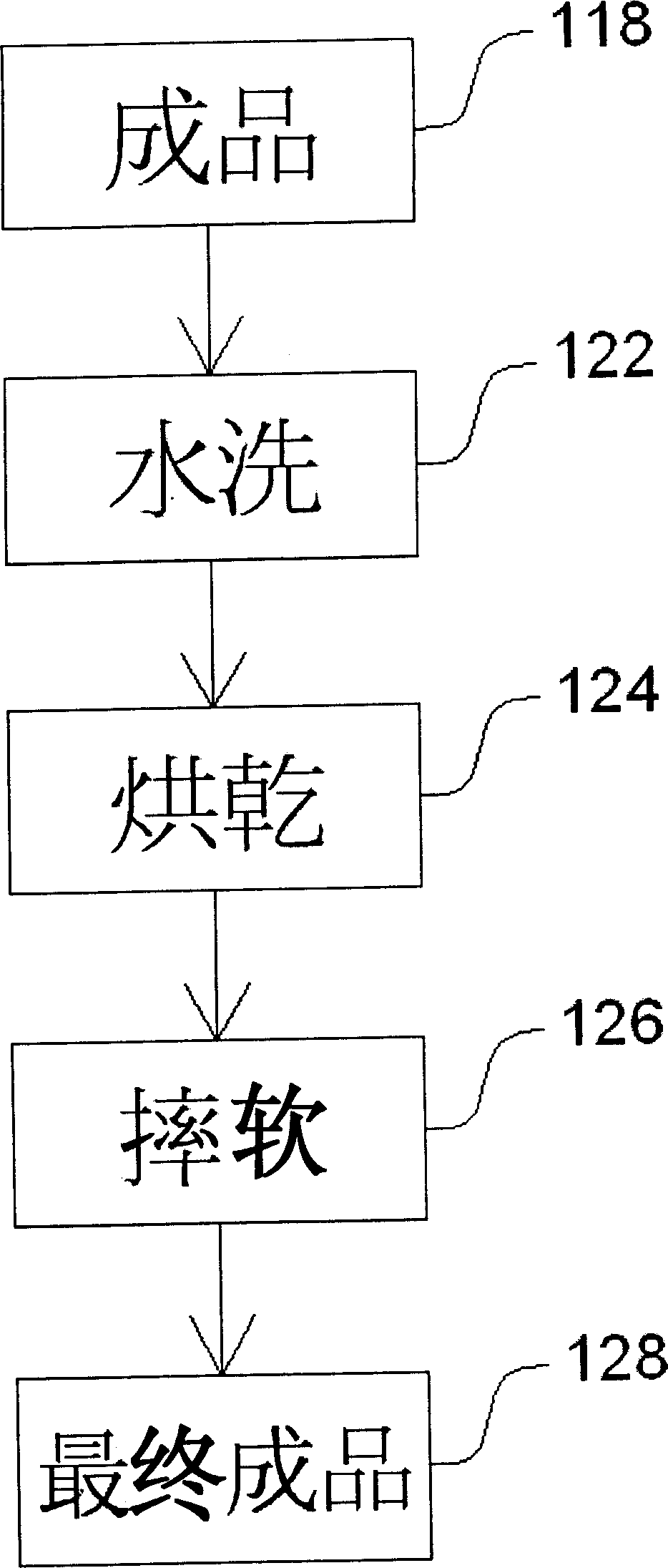

[0032]3 denier (nylon / polyester sea-island superfine fiber) and a nylon mesh reinforcing material with a thickness of 0.1mm are made into a non-woven base fabric with a weight of 400g / m2 and a thickness of 1.0mm through a needle rolling machine. Then the base cloth is sent to the weight reduction machine, and the easily soluble polyester (Co-PET) of the sea-island type superfine fiber is dissolved with a 10% strong alkali solution by weight percentage, washed and dried, and the base cloth is now The fineness of the nylon fiber in it is 0.07 denier. The base fabric after this reduction is dyed with acid dye (trade name: Irgalan Blue, weight percentage 4%, company name: CIBA) in a beam dyeing machine (Jigger), the temperature is 95 ° C and the constant temperature time is 60 minutes, and then washed with water and drying. The dyed base fabric is impregnated with water-based polymer elastomer resin, the water-based polymer elastomer resin is composed of water-based resin (trade ...

Embodiment 2

[0034] The fineness 3 denier (nylon / polyester sea-island superfine fiber) and the component nylon mesh reinforcing material of 0.1mm are made into a non-woven base fabric with a weight of 400g / m2 and a thickness of 1.0mm through a needle rolling machine. The base cloth is then sent to a weight reducing machine, and the polyester of the sea-island superfine fiber is dissolved with a 10% strong alkali solution by weight percentage, washed and dried. At this time, the fineness of the nylon fiber in the base cloth is 0.07. Danny. The base cloth after this reduction is dyed with acid dye (trade name: Irgalan Blue, weight percentage 4%, company name: CIBA) in a beam dyeing machine (Jigger), the temperature is 95 ℃ constant temperature time 60 minutes, then through washing and drying drying. The dyeing step described above is used to roughly adjust the color of the base fabric. The dyed base fabric is impregnated with water-based polymer elastomer resin, the water-based polymer ela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com