Pearl powder printing paste composition, preparing method thereof and application thereof

A technology of pearl powder and composition, which is applied in dyeing, textiles and papermaking, etc. It can solve the problems that pearls and pigments cannot be printed at the same time, and the printing process of pearl powder is complicated, etc., and achieve the effect of good fluidity and soft hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 pearl powder printing paste formula (1) and manual platen pearl powder screen printing process

[0040]

[0041] Process:

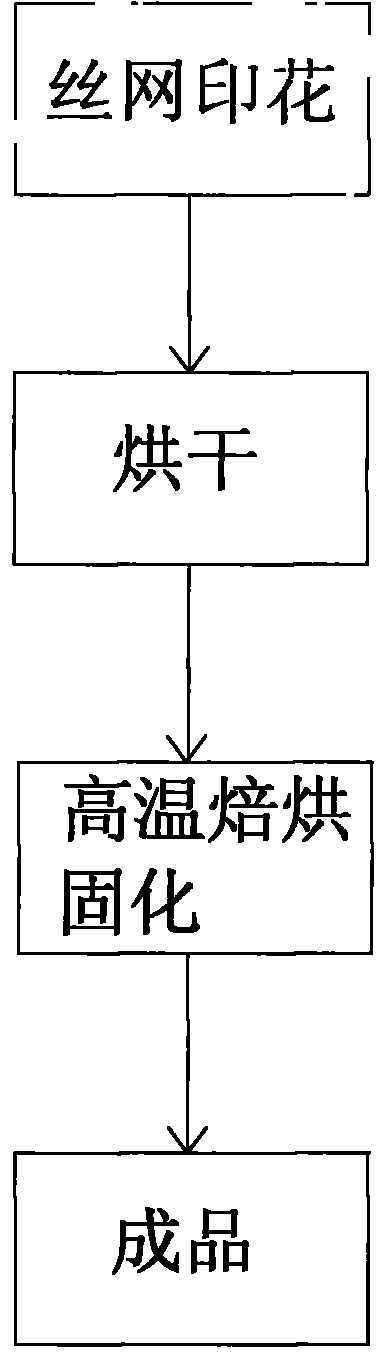

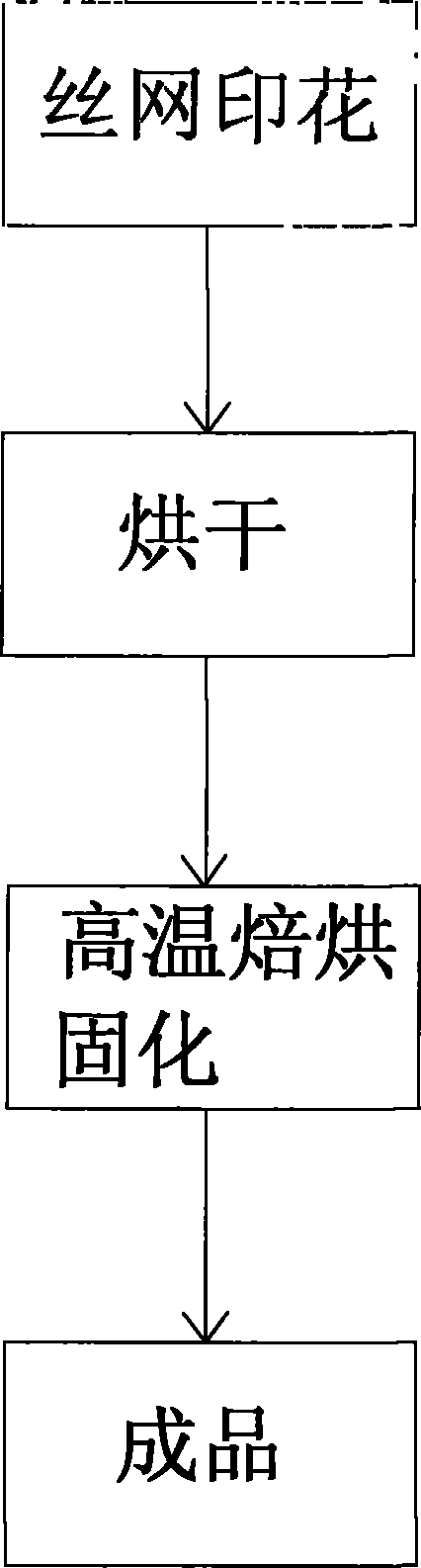

[0042] As shown in Figure 1, the resin platen is glued with silk, and then screen printing with pearl powder (choose 80 or 100 mesh monofilament screen), the number of times of screen printing with pearl powder: two round trips. Then bake at high temperature; bake at 140°C plus or minus 10°C for 3 minutes plus or minus 1 minute, and then drop the finished product. The equipment used is a conventional rotary screen printing machine, and the operation requirements are the same as the conventional paint printing process.

Embodiment 2

[0043] Embodiment 2 pearl powder printing paste formula (2) and manual platen pearl powder screen printing process

[0044]

[0045]

[0046] Printing process:

[0047] Such as figure 2 , Resin platen glued silk, and then pearl powder screen printing (choose 80 or 100 mesh monofilament screen), pearl powder screen printing times: two times back and forth. There is no need to bake at high temperature, and the required fastness can be reached after 24 hours of natural drying, and the finished product can be dropped off the machine. The equipment used is a conventional flat screen printing machine, and the operation requirements are the same as the conventional paint printing process.

Embodiment 3

[0048] Embodiment 3 pearl powder printing paste formula (3) and manual platen pearl powder, dyestuff synchronous screen printing process

[0049]

[0050] Printing process:

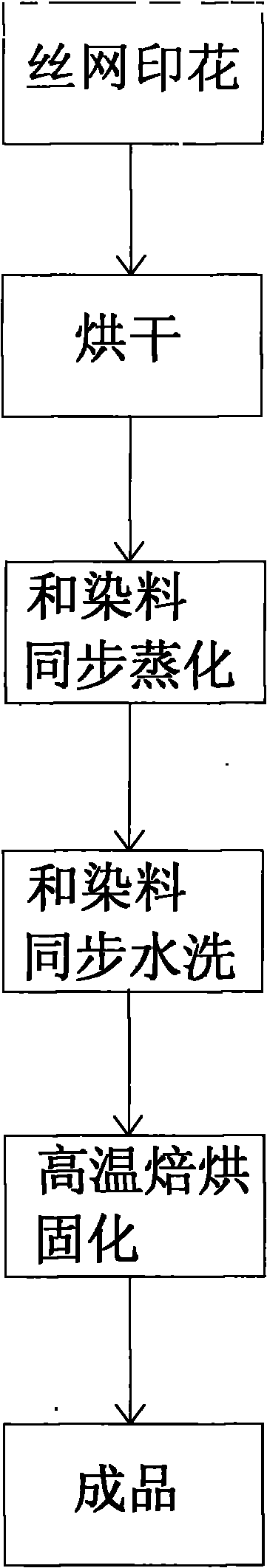

[0051] Such as image 3 , small powder paste paste silk; platen temperature: 30 degrees plus or minus 5 degrees. Choose 60-80 mesh monofilament screen for pearl powder screen printing; screen printing procedure: print dye and pearl powder first, or print pearl powder first and then overprint dye. The speed of machine printing, the angle of scraper, the number of screen printing times, steaming process and water washing process are all in accordance with the conventional process. Re-baking at high temperature: bake at 140 degrees plus or minus 10 degrees for 3 minutes plus or minus 1 minute, and then drop the finished product. The equipment used is a conventional flat screen printing machine, and the operation requirements are the same as the conventional paint printing process.

[0052] The quantit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com