Single abrasive paper cutting and inspecting machine

A product inspection machine and sandpaper technology, which is applied in the field of single-sheet sandpaper cutting and inspection machine, to achieve the effect of improving the authenticity rate, reducing missed inspections, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

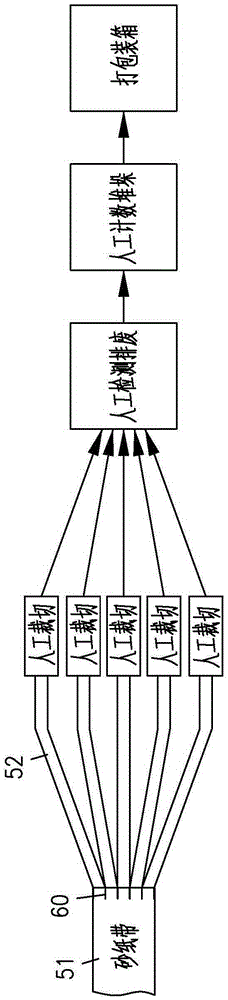

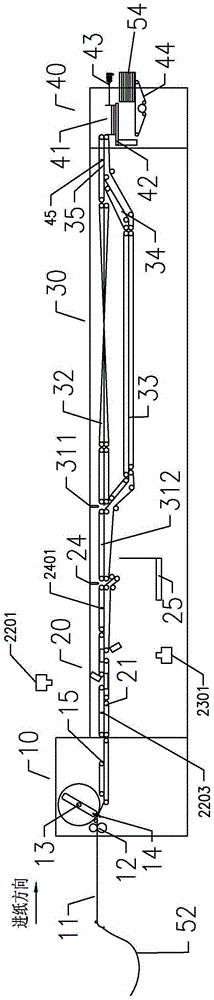

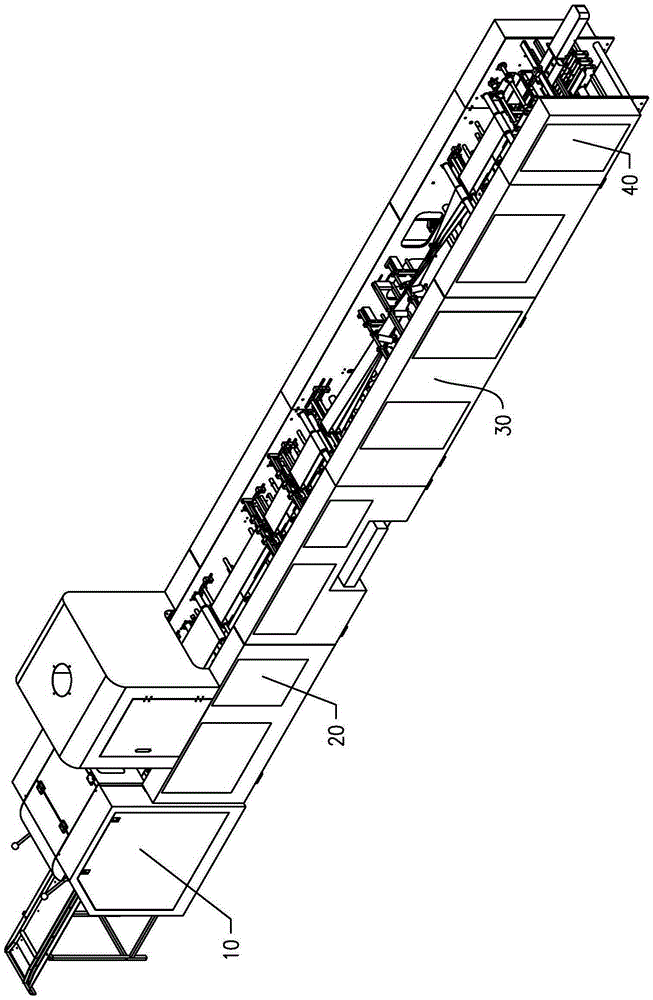

[0030] Such as figure 2 and image 3 As shown, the single-sheet sandpaper cutting and inspection machine of the present invention includes a cutting mechanism 10, a detection and waste discharge mechanism 20, an overturning conveying mechanism 30, and a counting and stacking mechanism 40, wherein: receiving and correcting linkage sandpaper production line (not shown in the figure) ) the wide-shaped belt-shaped sandpaper belt 51 produced is cut into a single abrasive belt 52 of a set width through n-1 slitter knives 60, and the lower knife is fixed and the upper knife is rotated to cut the abrasive belt 52 horizontally into a single block The output end of the cutting mechanism 10 of the shape sandpaper 53 is set corresponding to the input end of the detection waste discharge mechanism 20, and the gap between the adjacent sandpaper 53 is stretched to the length of a single sandpaper 53, and the sandpaper 53 is sanded on the surface and the printing surface. Qualified product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com