Reversed-polarity AlGaInP-based light-emitting diode and manufacturing method thereof

A technology of light-emitting diodes and manufacturing methods, which is applied in the field of optoelectronics, can solve problems affecting product quality and genuine product rate, poor metal layer adhesion, device voltage increase, etc., to improve quality and yield, improve adhesion and integrity, The effect of the integrity of the electrode structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

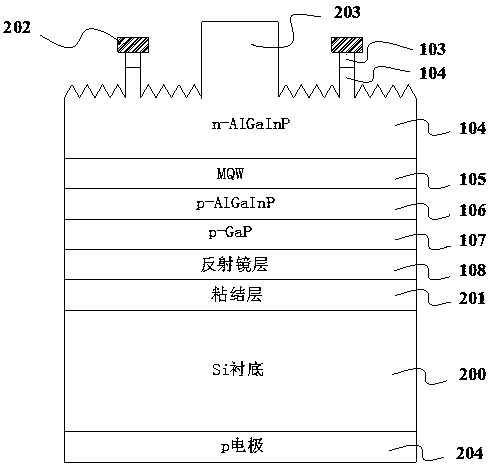

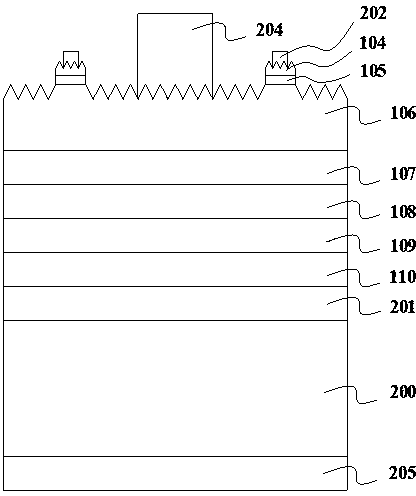

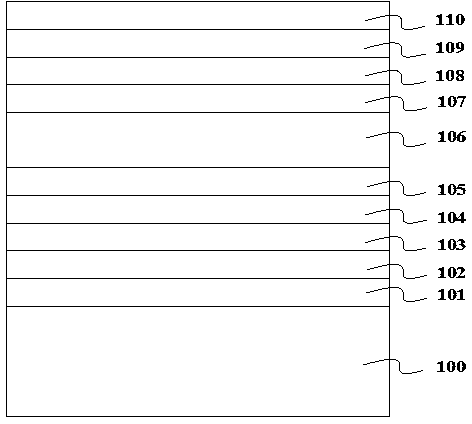

[0026] like figure 2 As shown, the present invention uses a Si substrate 200 as a permanent substrate, and has two main surfaces, upper and lower. Metal Au or Ag is used as the bonding layer 201 to form on its upper surface. The mirror layer 110 is formed on the bonding layer 201, and its material is a SiO2 / Ag double-layer structure; the p-GaP window layer 109 is formed on the mirror layer 110; the p-AlGaInP confinement layer 108 is formed on the p-GaP window On the layer 109; the multi-quantum well (MQW) active layer 107 is formed on the p-AlGaInP confinement layer 108, and its material is AlGaInP; the n-AlGaInP confinement layer 106 is formed on the multi-quantum well (MQW) active layer 107 On; the n-GaAs ohmic contact layer 105 is formed on the n-AlGaInP confinement layer 106, its thickness is preferably 300 Angstroms, and the doping concentratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com