Polyamide-imide binder for lithium ion battery and electrode plate

A polyamide-imide and polyamide-imide copolymer technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low interface infiltration, poor segment flexibility, and difficulty in realizing industrialization. To achieve the effect of simple preparation process and preparation conditions, strong bonding strength and flexibility, and improved safety in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

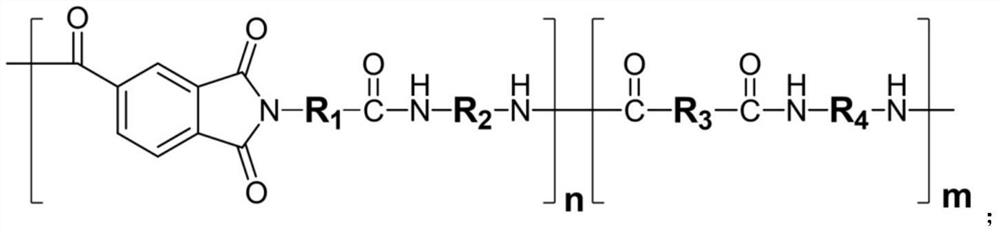

[0038] In the present embodiment, the electrode binder used contains the polyamide-imide copolymer of following structural formula:

[0039]

[0040] Wherein, n:m=75:25 in the synthesized polyamide-imide copolymer.

[0041] Its preparation method is:

[0042] Put 384.3g of trimellitic anhydride, 402.6g of aminoundecanoic acid and 2.50L of glacial acetic acid into a 5L reactor, heat up to 120°C and react for 2 hours, then cool and stand still, filter out the white precipitate, and wash it fully with ethanol to obtain Diacid monomer TMA-11.

[0043] Put 212.3g of 4,4-diaminobenzophenone, 281.6g of TMA-11 and 57.6g of 1,12-dodecanedioic acid into the autoclave, add 165g of deionized water, through repeated vacuuming and Fill the reactor with nitrogen to replace the gas. Seal the reaction kettle and raise the temperature to 230°C while stirring. At this time, discharge water vapor through the exhaust valve to keep the pressure in the kettle constant. The reaction was carried...

Embodiment 2

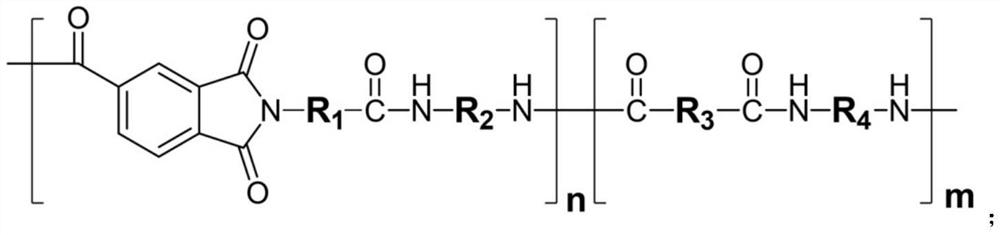

[0045] In the present embodiment, the electrode binder used contains the polyamide-imide copolymer of following structural formula:

[0046]

[0047] Wherein, n:m=75:25 in the synthesized polyamide-imide copolymer.

[0048] In the preparation, except that 4,4-diaminobenzophenone was replaced by p-phenylenediamine in Example 1, the same method as in Example 1 was used to obtain the polyamideimide described in this example copolymer.

Embodiment 3

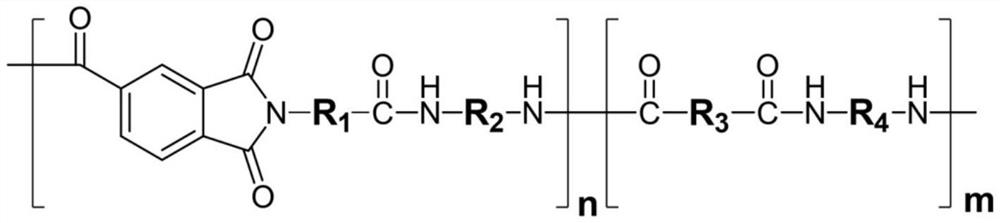

[0050] In the present embodiment, the electrode binder used contains the polyamide-imide copolymer of following structural formula:

[0051]

[0052] Wherein, n:m=75:25 in the synthesized polyamide-imide copolymer.

[0053] In the preparation, except that aminoundecanoic acid in Example 1 was replaced with 2-aminodecanoic acid, the same method as in Example 1 was used to obtain the polyamideimide copolymer described in this example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com