Lithium-carbon dioxide battery positive electrode material and application thereof

A carbon dioxide, battery cathode technology, applied in battery electrodes, fuel cells, circuits, etc., can solve the problems of using high-temperature equipment such as tube furnaces, increasing the cost of precious metals, and less catalytic active sites, and achieving solutions to large charge-discharge potential differences, The effect of complete electrode structure and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

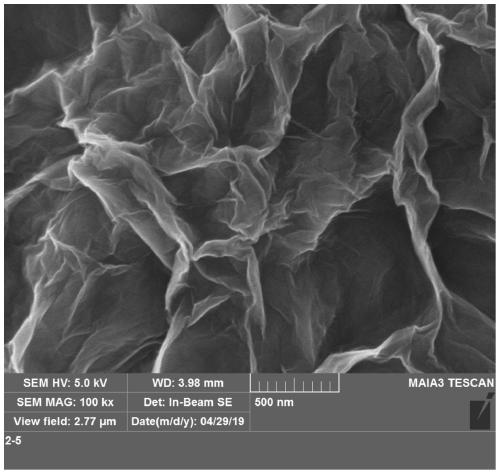

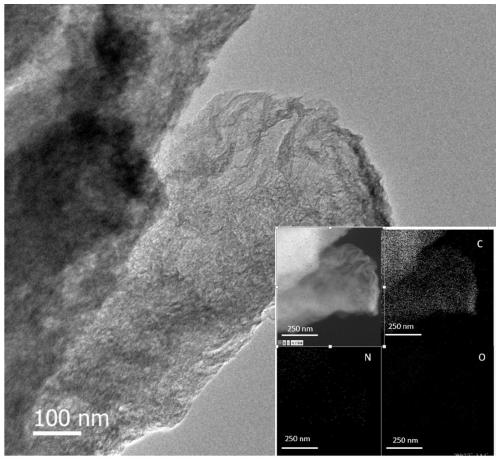

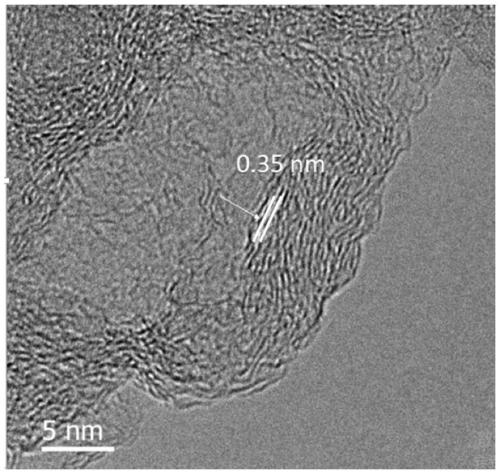

[0044] This embodiment provides the preparation of a positive electrode material for a lithium carbon dioxide battery, comprising the following steps:

[0045] 1) Graphene oxide GO was prepared by the modified Hummer method:

[0046] Add 2.5 grams of potassium persulfate, 2.5 grams of phosphorus pentoxide and 3 grams of graphite powder into 12 milliliters of 96wt% concentrated sulfuric acid at 80°C and stir for 4.5 hours. After cooling, add deionized water and then centrifugally dry to obtain preoxidized graphite powder;

[0047]Add the pre-oxidized graphite powder to 120 ml of 96% concentrated sulfuric acid in an ice bath, add 15 mg of potassium permanganate and stir at 35°C for 2 hours, then add 250 ml of deionized water and stir for 2 hours, then add 700 ml to Ionized water and 20 milliliters of 30wt% hydrogen peroxide, the solution turns bright brownish yellow; use 1 liter of dilute hydrochloric acid with a mass fraction of 0.1 to filter and wash, then wash with water and...

Embodiment 2

[0056] This embodiment provides a preparation of a lithium carbon dioxide battery, comprising the following steps:

[0057] 1) Preparation of positive electrode of lithium carbon dioxide battery:

[0058] Take 12 mg of the lithium carbon dioxide battery cathode material prepared in Example 1 and mix it with 2 mg of polyvinylidene fluoride PVDF, stir it into a slurry with N-methylpyrrolidone as a solvent, and coat the slurry on a carbon paper of 40 square centimeters , dried in a vacuum oven at 80°C, cut into small discs with a diameter of 12 mm at room temperature, which is the positive electrode of the lithium carbon dioxide battery, and the loading capacity of the positive electrode material of the lithium carbon dioxide battery is 0.3 mg / cm 2 ;

[0059] II) Preparation of CR2032 button cell with holes:

[0060] The assembly of the CR2032 button cell with holes is completed in a glove box full of argon, with the lithium sheet as the negative pole, and the positive pole of ...

Embodiment 3

[0067] This example provides the preparation of a cathode material for a lithium carbon dioxide battery. The steps of the method are the same as those in Example 1, except that the ammonia water with a mass fraction of 25% in step 2) is replaced with a hydrazine hydrate solution with a mass fraction of 25% to obtain Aminated graphene oxide GO-N 2 h 4 . h 2 O is the anode material for lithium carbon dioxide batteries.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com