High-performance lithium ion battery aluminum-based negative electrode material and preparation method thereof

A technology of aluminum trichloride and aluminum acetylacetonate, applied in battery electrodes, secondary batteries, nanotechnology for materials and surface science, etc. Stability deterioration and other issues, to achieve excellent cycle stability, improve conductivity, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

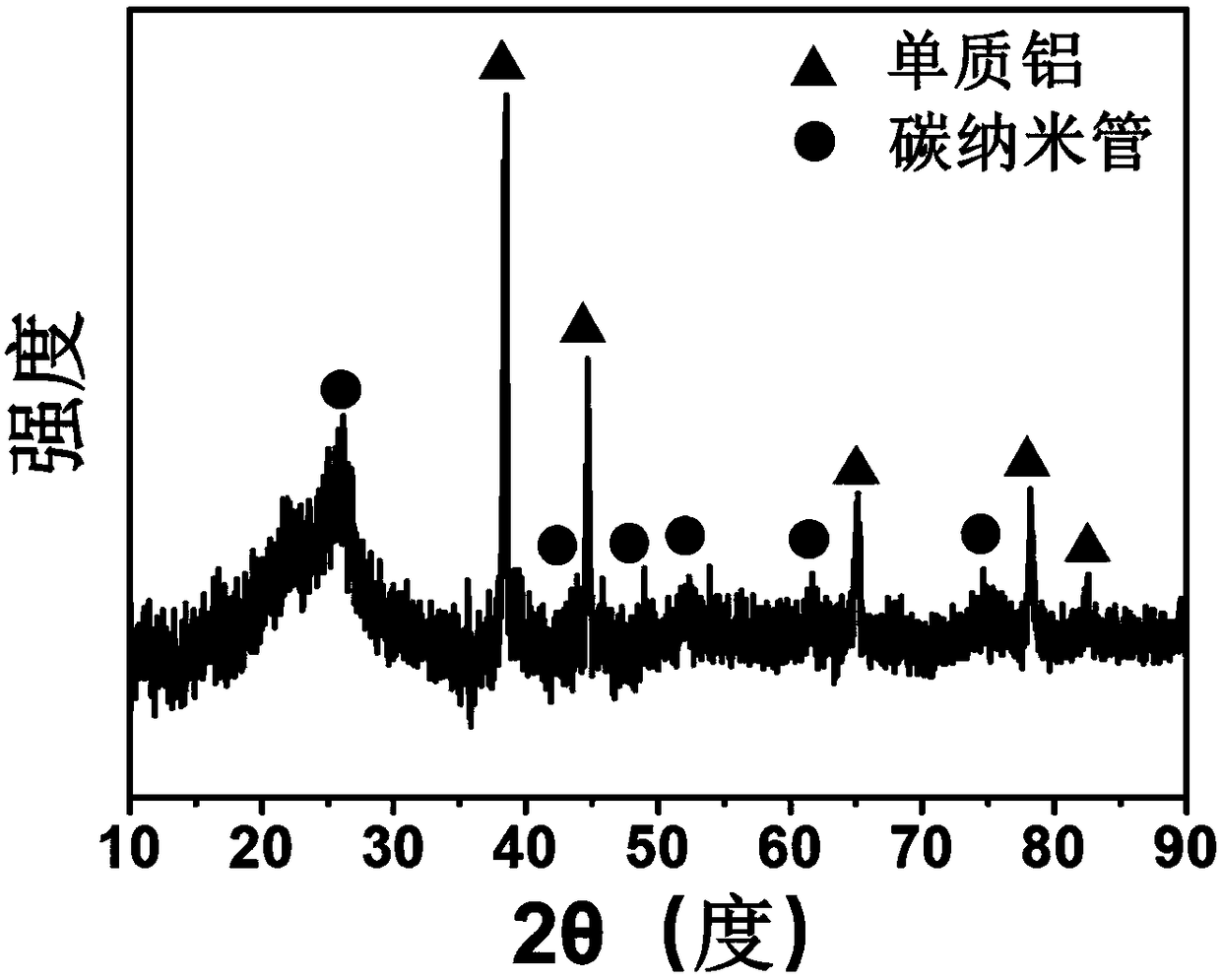

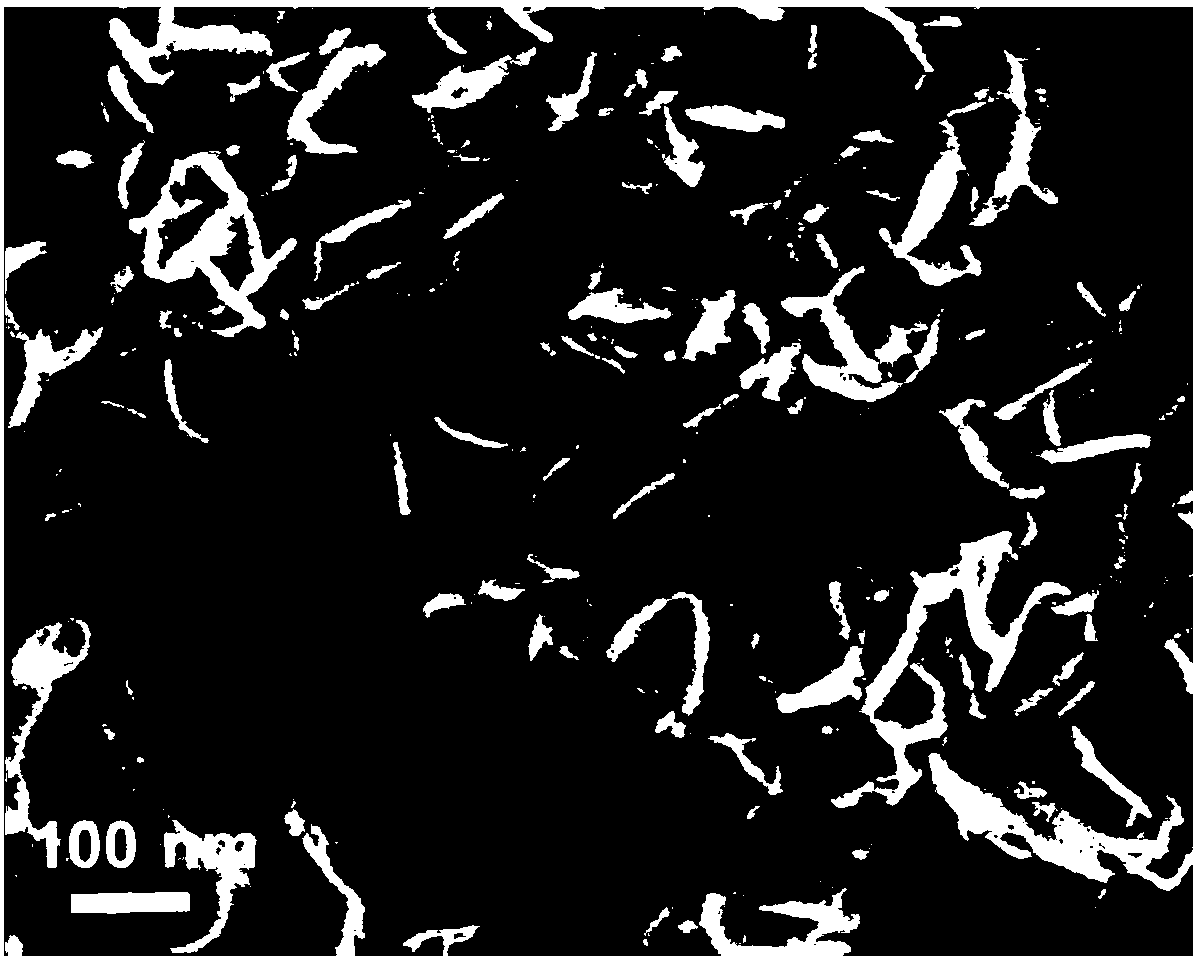

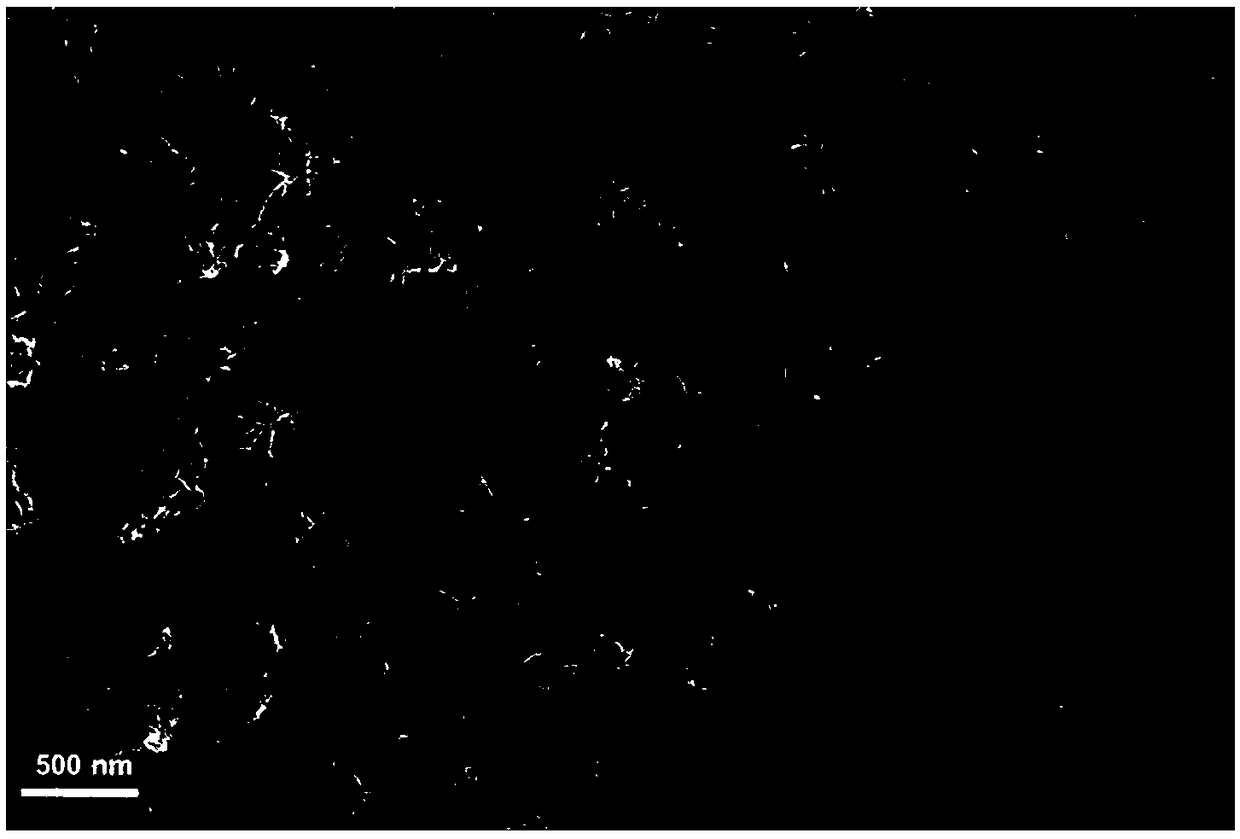

Embodiment 1

[0053] Firstly, under the condition of stirring at 60° C., 0.05 g of carbon nanotubes were added into 40 ml of anhydrous trimethylbenzene to make them uniformly dispersed. Then add 0.052g of aluminum trichloride, 0.032g of aluminum acetylacetonate and 0.0575g of lithium aluminum hydride to the system in sequence, then raise the temperature to 140°C, and react under normal pressure for 4 hours to obtain carbon nanotubes and Al nanosheets The initial product of the compound. After the reaction was complete, the reaction vessel was taken out and cooled to room temperature. Then put the initial product into a centrifuge tube and centrifuge at a speed of 8000rpm for 5 minutes to obtain a gray-black solid substance. Then add 20ml of anhydrous acetone, ultrasonically wash to remove by-products such as lithium chloride, continue to centrifuge at 8000rpm for 5 minutes, repeat this washing process 3 times, and obtain a gray-black product, which is placed in a vacuum oven to dry at room...

Embodiment 2

[0056] First, under the condition of stirring at 60°C, 0.025g of carbon nanotubes was added into 40ml of anhydrous trimethylbenzene to make them uniformly dispersed. Then add 0.052g of aluminum trichloride, 0.032g of aluminum acetylacetonate and 0.0575g of lithium aluminum hydride to the system in sequence, then raise the temperature to 140°C, and react under normal pressure for 4 hours to obtain carbon nanotubes and Al nanosheets The initial product of the compound. After the reaction was complete, the reaction vessel was taken out and cooled to room temperature. Then put the initial product into a centrifuge tube and centrifuge at a speed of 8000rpm for 5 minutes to obtain a gray-black solid substance. Then add 20ml of anhydrous acetone, ultrasonically wash to remove by-products such as lithium chloride, continue to centrifuge at 8000rpm for 5 minutes, repeat this washing process 3 times, and obtain a gray-black product, which is placed in a vacuum oven to dry at room tempe...

Embodiment 3

[0059] Firstly, under the condition of stirring at 60° C., 0.1 g of carbon nanotubes were added into 40 ml of anhydrous trimethylbenzene to make them uniformly dispersed. Then add 0.052g of aluminum trichloride, 0.032g of aluminum acetylacetonate and 0.0575g of lithium aluminum hydride to the system in sequence, then raise the temperature to 140°C, and react under normal pressure for 4 hours to obtain carbon nanotubes and Al nanosheets The initial product of the compound. After the reaction was complete, the reaction vessel was taken out and cooled to room temperature. Then put the initial product into a centrifuge tube and centrifuge at a speed of 8000rpm for 5 minutes to obtain a gray-black solid substance. Then add 20ml of anhydrous acetone, ultrasonically wash to remove by-products such as lithium chloride, continue to centrifuge at 8000rpm for 5 minutes, repeat this washing process 3 times, and obtain a gray-black product, which is placed in a vacuum oven to dry at room ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com