Method for processing blanched untwisted relief towels

A processing method and hot ironing technology, which is applied to embossed fabrics, textiles, papermaking, household appliances, etc., can solve the problems that the embossed part is not easy to cut out, the promotion and development are limited, and the shrinkage ratio is low, so as to achieve three-dimensional embossment Strong sense, low cost, large shrinkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

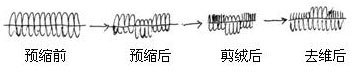

[0015] A processing method for hot-ironing untwisted embossed towels, comprising the following steps:

[0016] (1) Use high-temperature water-soluble vinylon yarn (60-80 counts) above 90°C and cotton yarn in parallel twist, and the parallel twist is the single yarn twist of the combined cotton yarn to make untwisted water-soluble yarn;

[0017] (2) The untwisted water-soluble yarn and ordinary yarn obtained in step (1) are warped at intervals at a ratio of 1:1 to make wool warp beams, and interwoven with ground warp and weft yarns to form jacquard patterns;

[0018] (3) Moisten the high-temperature roller with water and scald to ensure that the temperature of the cloth surface does not exceed 80-90°C, so that the untwisted part shrinks and the part that needs to be sheared protrudes;

[0019] (4) After drying with hot air, use a shearing machine to cut the raised parts that need to be cut, and then cut again to improve the smoothness of the suede.

[0020] (5) Use high temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com