Adjusting method of stainless-steel cold continuous-rolling roll gap

An adjustment method, stainless steel technology, applied in rolling force/roll gap control, program control in sequence/logic controller, electrical program control, etc., can solve the problem of low strip yield and low roll gap setting accuracy , thickness out of tolerance and large length, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

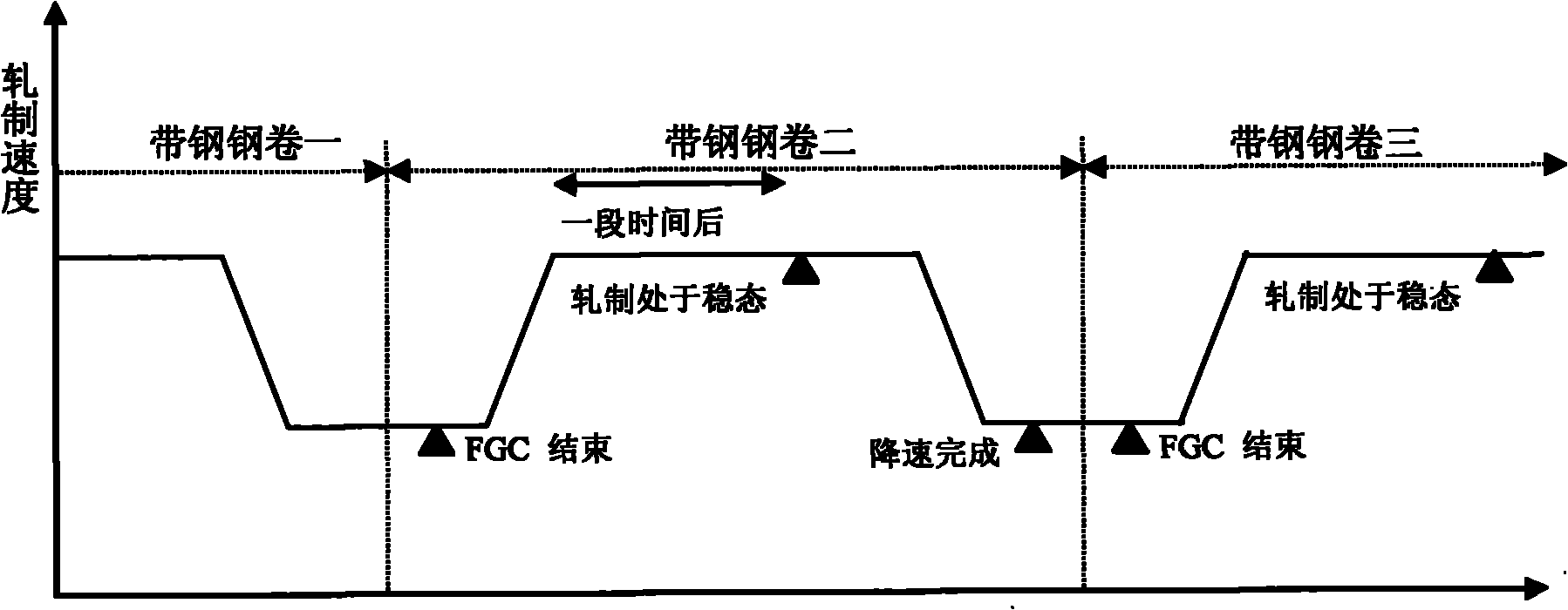

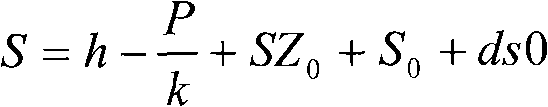

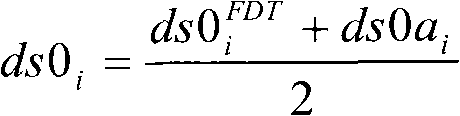

[0018] In the roll gap adjustment method of continuous stainless steel rolling of the present invention, the process control level L2 receives the original data of the roll and the strip steel to be rolled from the production control level L3, and the process control level adopts the roll gap calculation mathematical model according to the original data to calculate The roll gap value of the next strip at steady state, the roll gap value of the current strip at low speed, the roll gap value of the current / next strip at transient state, the roll gap value of the next strip at low speed, and calculate The roll gap adjustment amount from the current low-speed change of rolling the current strip to the current / next transient state, the roll gap adjustment amount from the current / next transient change to the low-speed rolling of the next strip, process control level The calculated roll gap value of the next strip steel in steady state, the roll gap adjustment amount from the low spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com