A Pass Transfer Control Method Adaptive to Rolling Force for Reversing Rolling Mills

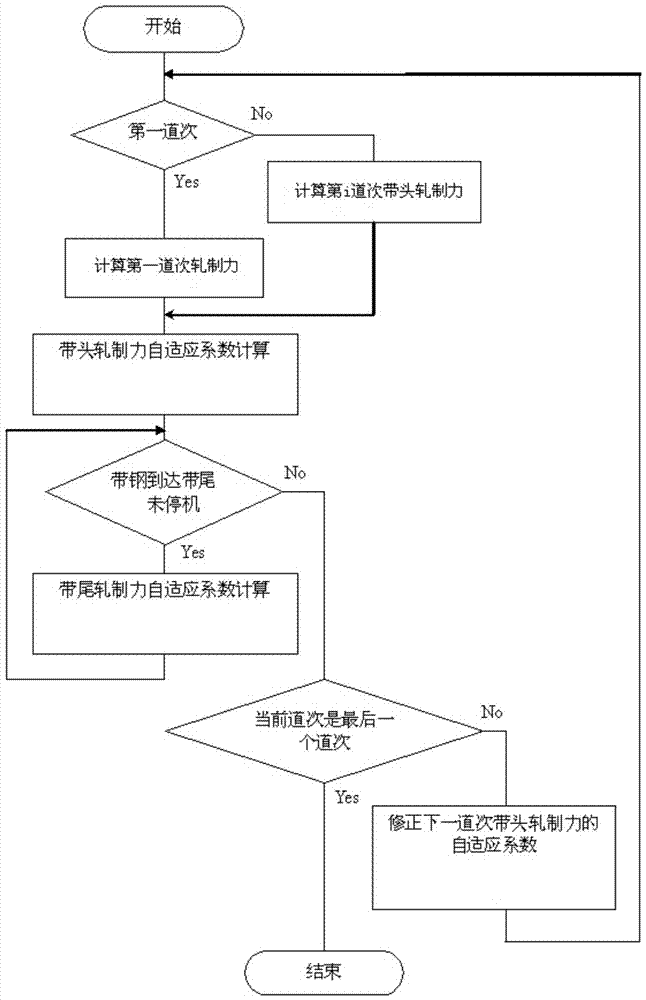

A control method and rolling force technology, applied in the field of control, can solve problems such as large fluctuations in the calculation results of collected data, fluctuations in strip strength, and out-of-tolerance problems, so as to improve rolling stability and thickness control accuracy, and reduce thickness overshoots. The difference length and the effect of improving the calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0081] When producing strips of a certain material specification in batches, a reversible rolling mill of the present invention uses a rolling force adaptive pass transfer control method to complete the calculation of the rolling force adaptive coefficient of the head and tail of the coil, And use these coefficients to complete the control steps of rolling force adaptive coefficient transmission between passes, and its various embodiments are as follows:

[0082] 1st pass:

[0083] 1) Calculation of the setting value of rolling force at the head

[0084] P 1 =P C1 ·CP H1 -1 =643*0.9874=635(ton)

[0085] 2) Calculation of adaptive coefficient of rolling force at the head

[0086] P HA1 =632(ton)

[0087] P CHA1 =638(ton)

[0088]

[0089] CP H1 -1 =0.9874

[0090] CP H1 =0.9874+0.5*(0.9906-0.9874)=0.9890

[0091] 3) Calculation of adaptive coefficient of strip tail rolling force

[0092] When the tail of the strip is decelerated and reaches the strip threadin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com