Optimization method for hot rolled strip steel roll gap model

A hot-rolled strip steel and optimization method technology, applied in the direction of rolling force/roll gap control, etc., can solve the problems of roll gap zero point drift and low precision of roll gap self-learning model, so as to improve the setting accuracy and optimize the model structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing.

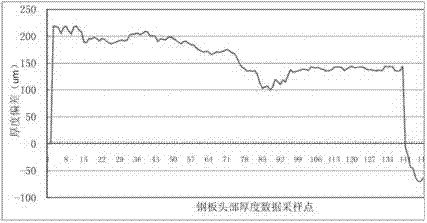

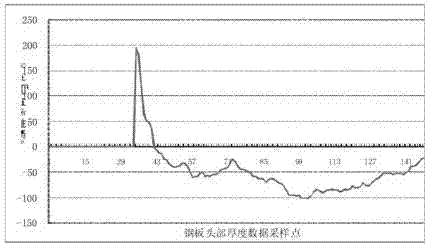

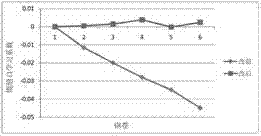

[0033] A hot-rolled strip steel roll gap model optimization method applied in the hot rolling production process. The present invention optimizes the roll gap setting calculation model structure; improves the roll gap self-learning data processing method, and optimizes the roll gap self-learning method, which can effectively Improving the setting accuracy of hot strip roll gap model.

[0034] The specific steps of the roll gap setting calculation model structure of the present invention will be described in detail below.

[0035] (1) Considering the influence of roll gap zero point drift, optimize the calculation model structure of roll gap setting.

[0036] The original roll gap setting calculation model is as follows:

[0037] Gap = Fh - ( S - ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com