Medium plate laminar cooling chain edge part shading device control method

A technology of a shielding device and a control method, which is applied in the direction of temperature control, etc., and can solve the problem of large temperature difference in the width direction of the steel plate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

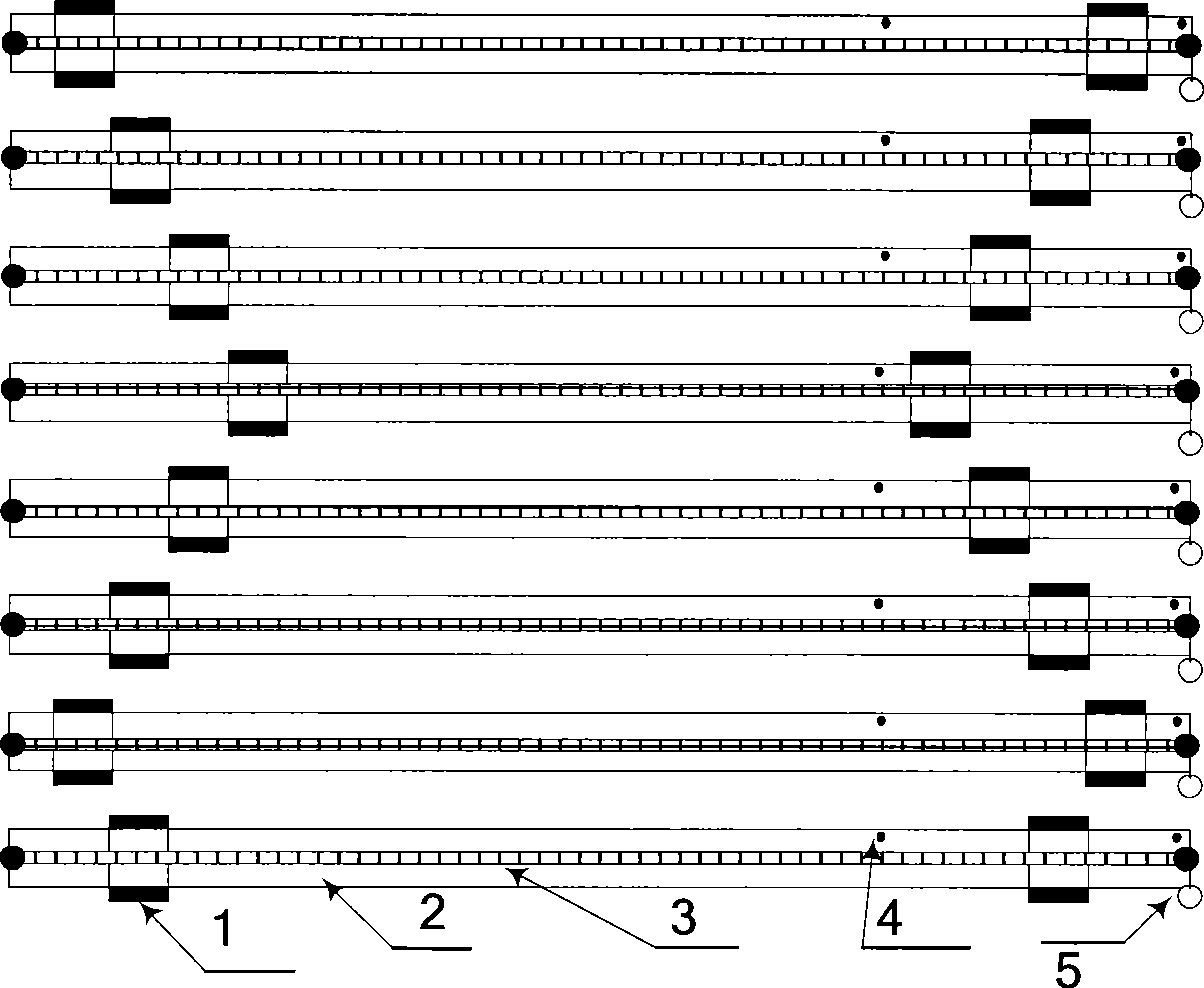

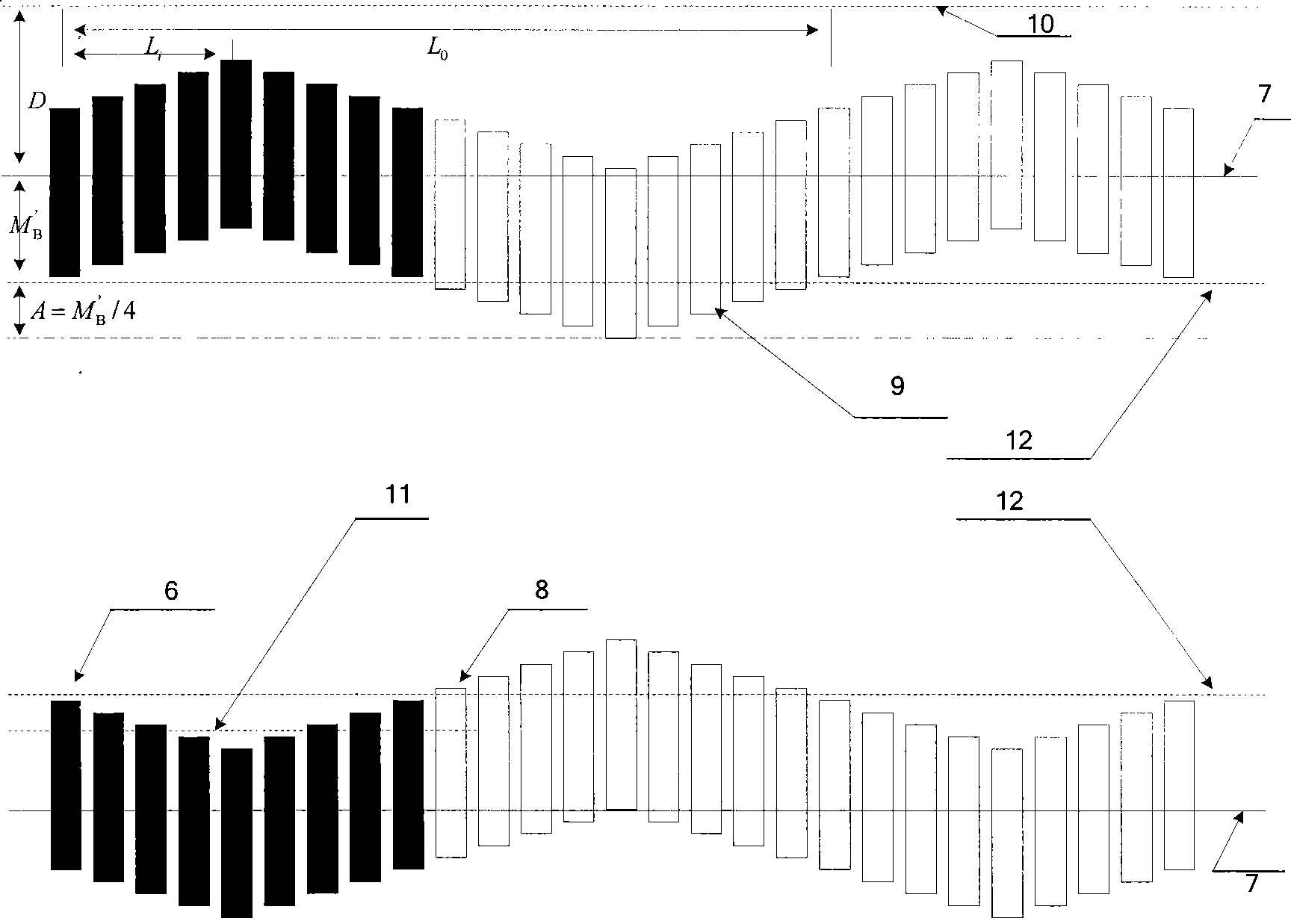

Method used

Image

Examples

Embodiment Construction

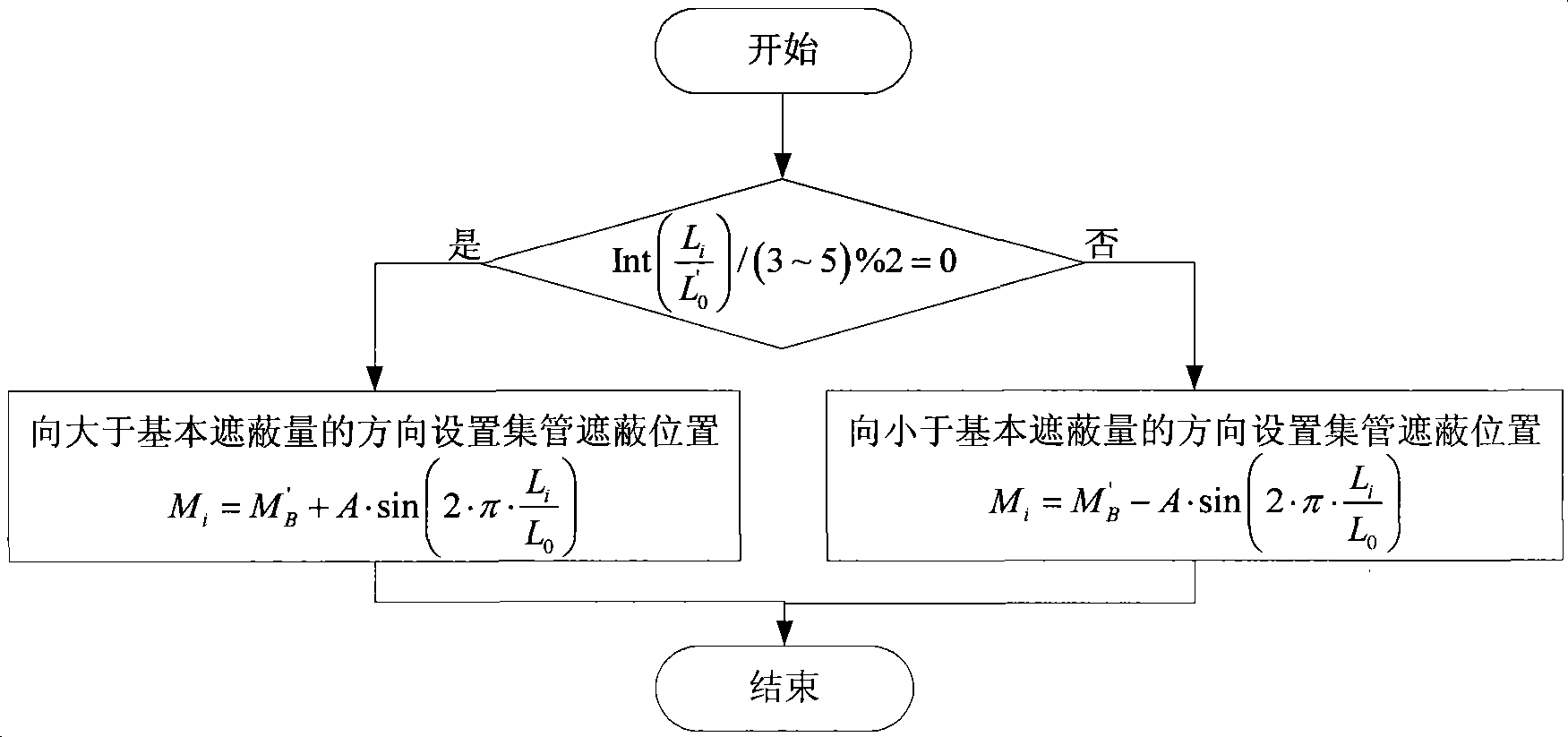

[0091] The setting steps of the control method of the edge masking device are as follows: Figure 7 As shown, taking the steel plate with furnace number 3C5791P32_1 as an example, the specific implementation method is as follows:

[0092] (1) The specific specifications of 3C5791P32_1 are as follows: the steel type is Q345C, the width is 2000mm, and the thickness is 20mm. The starting cooling temperature is 830°C, and the final cooling target temperature is 650°C. First of all, according to the steel type layer, thickness layer, width layer, opening and cooling temperature layer and water flow density layer, the corresponding long-term self-learning coefficient f of the steel plate read in the self-learning file L =0.88, since this steel plate is the first steel plate of the same specification, so select f L A self-learned correction factor calculated as an edge shading setting. Before being replaced with steel plates of other specifications for rolling, the remaining steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com