Thickness adaptive fuzzy control method for aluminium plate band rolling mill

A technology of self-adaptive fuzzy and control method, applied in the fields of rolling mill control device, metal rolling, metal rolling, etc., can solve the problems of difficulty in obtaining manual control experience stably, complex rolling process, low adaptability, etc., to improve the system The effect of speed of response, increased productivity, and reduced scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

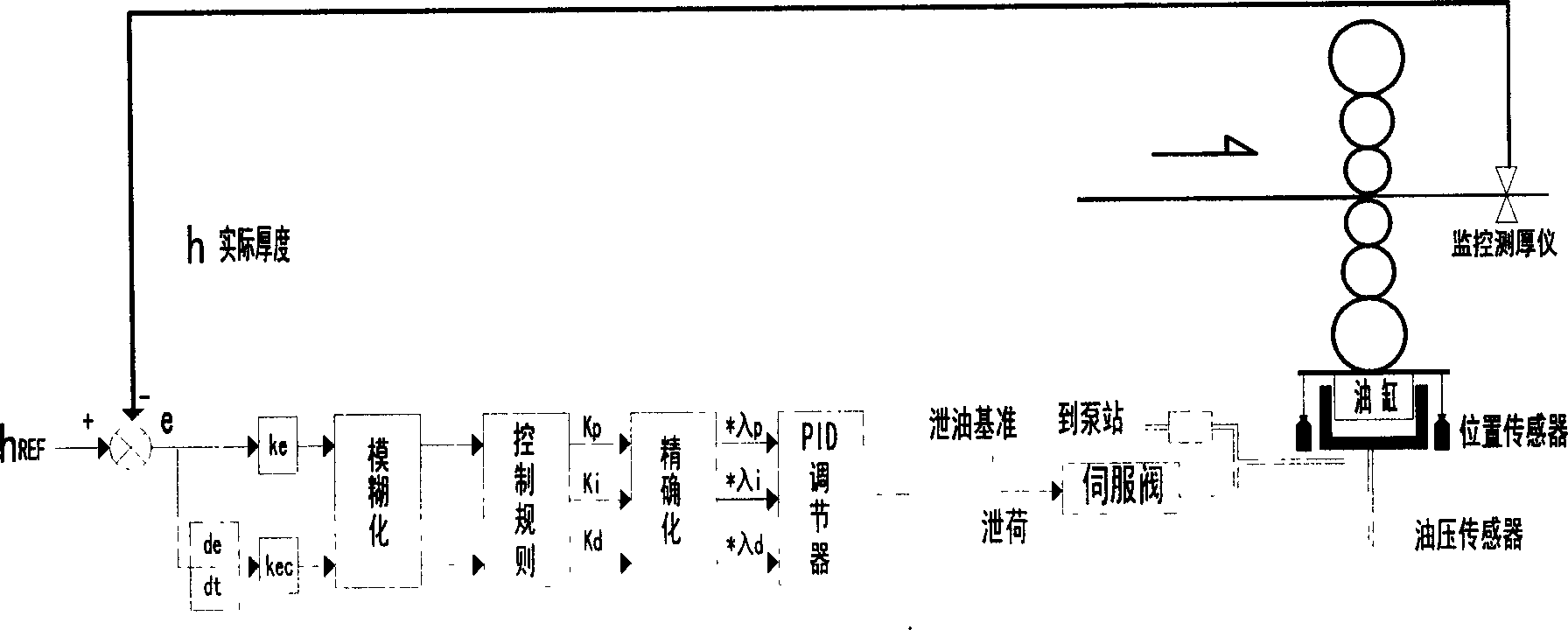

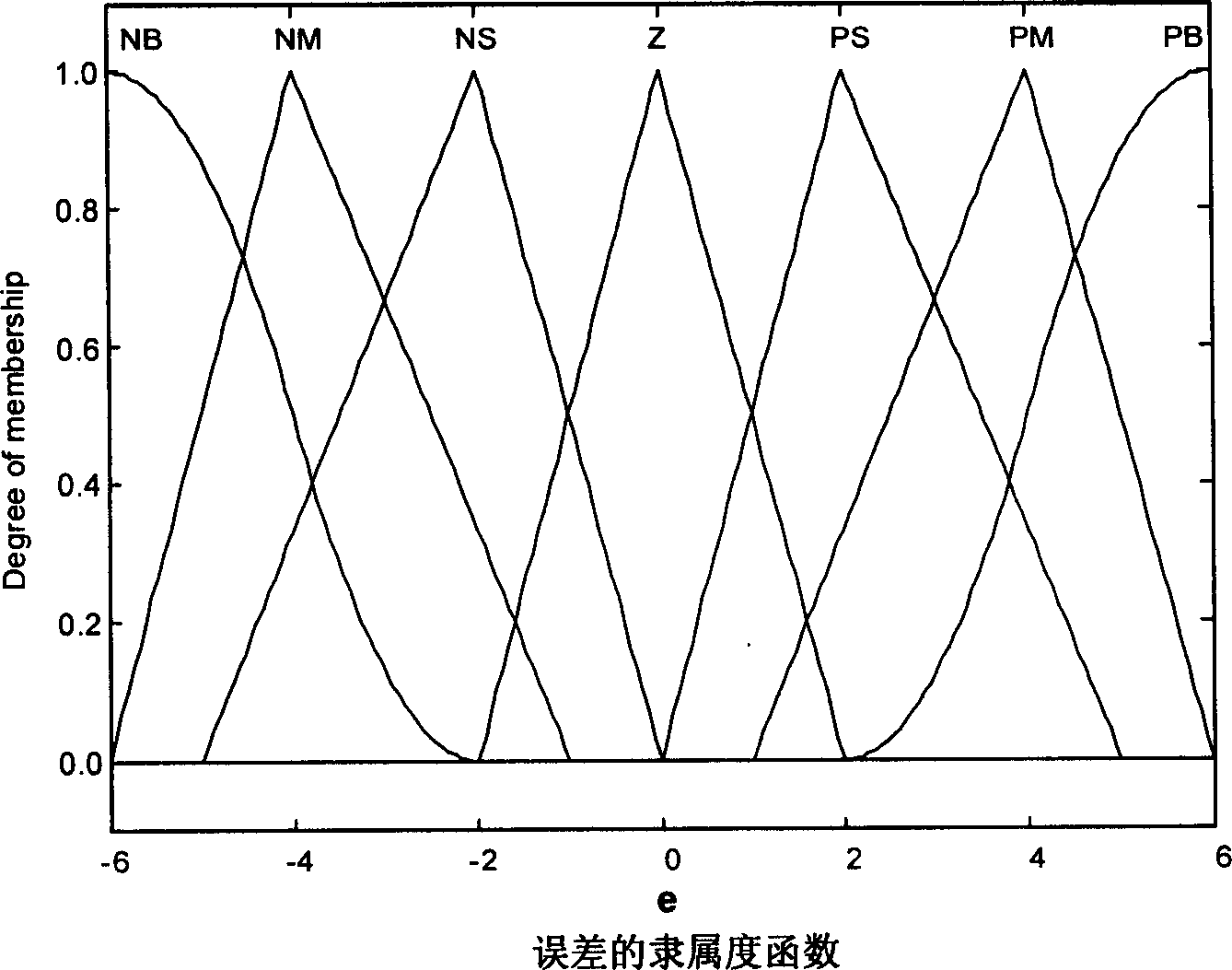

[0018] Fuzzy control is a control law based on knowledge rules and even semantic descriptions. It proposes an easier design method for nonlinear controllers, especially when the controlled device contains uncertainties that are difficult to deal with by conventional nonlinear control theory. effective. On the basis of the traditional PID control method, the present invention introduces a fuzzy control method, thereby forming a complete and feasible aluminum strip mill thickness adaptive fuzzy control method, and has achieved relatively satisfactory application effects.

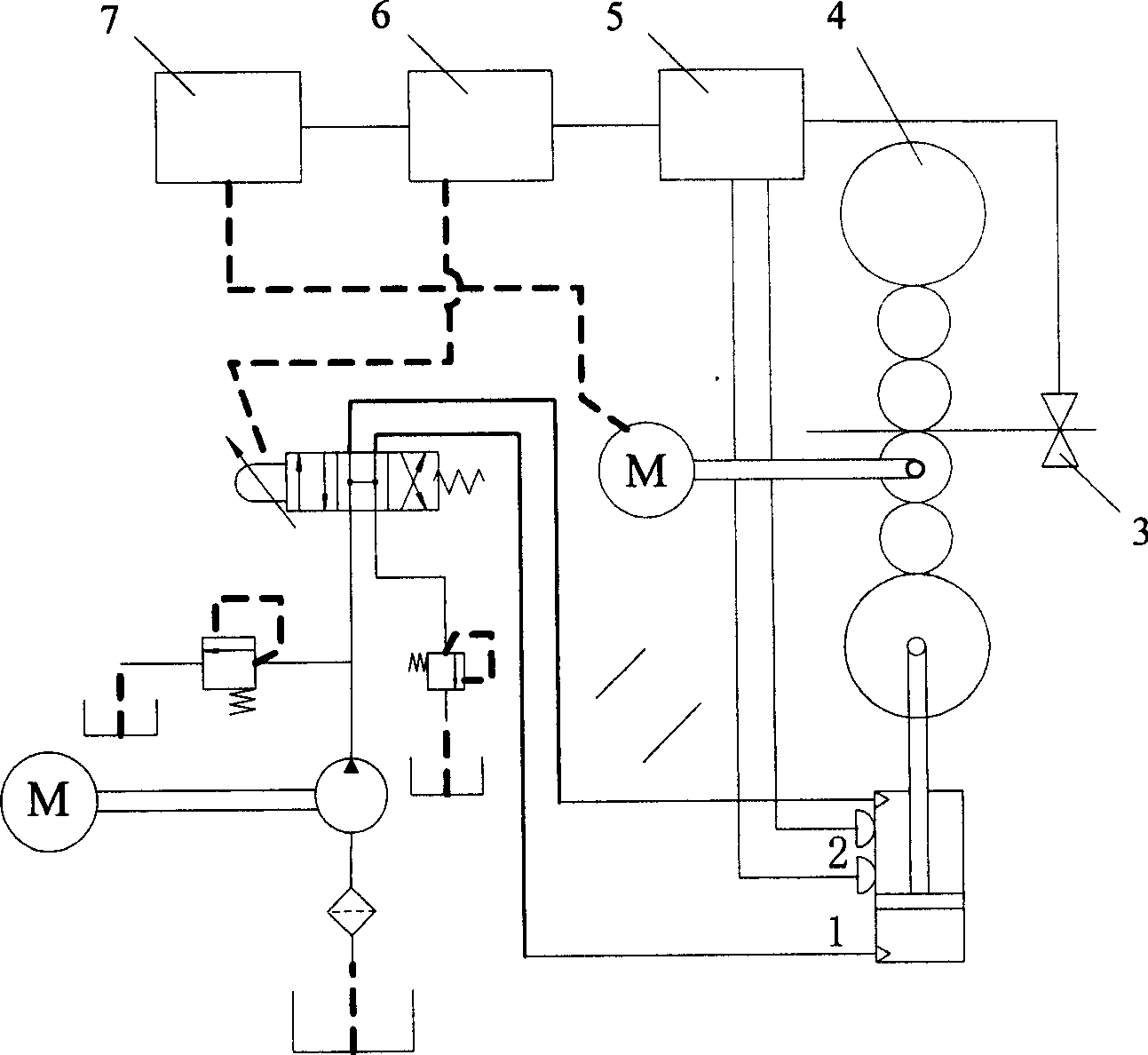

[0019] figure 1 It is a schematic diagram of the structure of the thickness control system of the aluminum strip rolling mill: during the aluminum strip rolling process, the rolling mill is controlled by 6 (embedded PC) and 7 (DC drive control system) to enter the rolling process. At this time, the thickness control system receives the thickness measurement device 3 The thickness difference signal detected is ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com