Ti and Al control method for nickel-based air valve alloy steel electroslag remelting

A technology of electroslag remelting and control method, which is applied in Al control and Ti field of electroslag remelting of nickel-based valve alloy steel, which can solve the difficult control of Ti and Al content, uneven Ti and Al content, Ti, Al Burning loss and other problems, to achieve the effect of ensuring product yield, ensuring smelting quality, and reducing head-to-tail deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-12

[0019] Examples 1-12: Ti, Al control method of the Nickel-based gas valve alloy steel, and the Al control method, using the following specific processes.

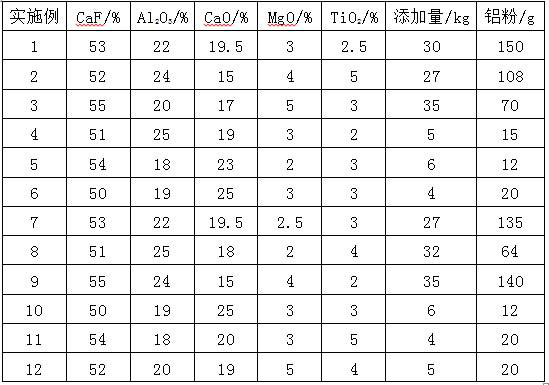

[0020] (1) The steel type, crystallizer size of each embodiment is used to protect the argon atmosphere, and the TI and Al range requirements in the alloy, and the target component of the electric slag is 1.

[0021] Table 1: Electroslag remelting target in each embodiment

[0022]

[0023] (2) The amount of the electric slag heavyweeling system and the amount of addition of each embodiment are shown in Table 2.

[0024] Table 2: Electroslagic slag system used in each of the examples

[0025]

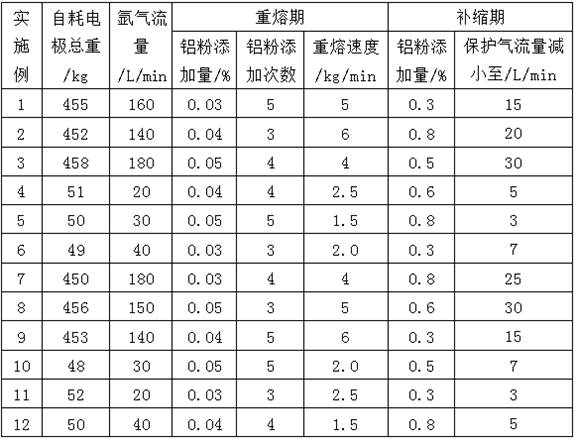

[0026] (3) The electroslag remelting process control process is shown in Table 3, which is protected by argon.

[0027] Table 3: Control Process of Embodiments

[0028]

[0029] In Table 3, the amount of aluminum powder addition in the remelting period is the ratio of the quality of the self-consuming electrode. The amount of alumi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com