Post-rolling cooling long-termed self-learning method based on case-based reasoning

A self-learning method and case-based technology, applied in metal rolling, metal rolling, workpiece surface treatment equipment, etc., can solve problems such as coiling difficulties and production stoppages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention is described in detail in combination with specific embodiments and accompanying drawings.

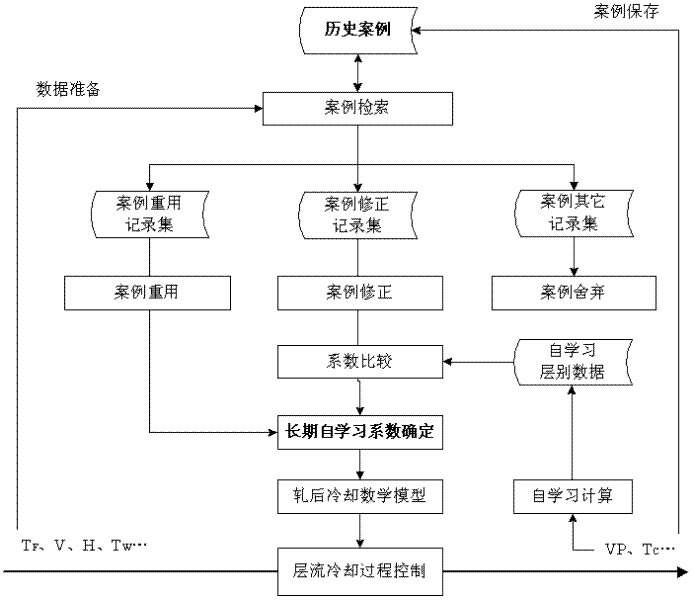

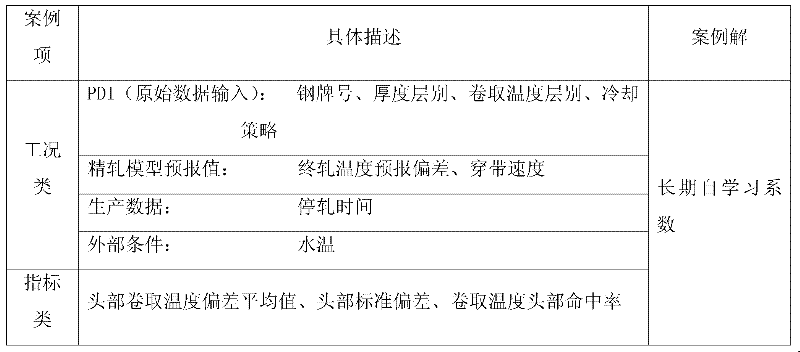

[0040] As shown in the attached figure, when rolling the first piece of steel or initial coil for specification change, the post-rolling cooling model first extracts the descriptive features of the current operating conditions (final rolling temperature T F , rolling speed V, rolling piece thickness H, water temperature T W etc.), and retrieve historical cases similar to the current working conditions in the case library according to this description feature. After two-stage filtering, the long-term self-learning coefficients of qualified highly similar working conditions are directly reused; the long-term self-learning coefficients of relatively similar working conditions are corrected, based on actual production considerations, in order to avoid head chilling or overcooling, It needs to be compared with the model self-learning layer data, and the larger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com