Method for controlling middle, low grade electric steel rolling using conventional rolling model

A technology of electrical steel and low grades, applied in rolling mill control devices, metal rolling, manufacturing tools, etc., can solve problems such as poor control accuracy, and achieve the effect of improving accuracy and setting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

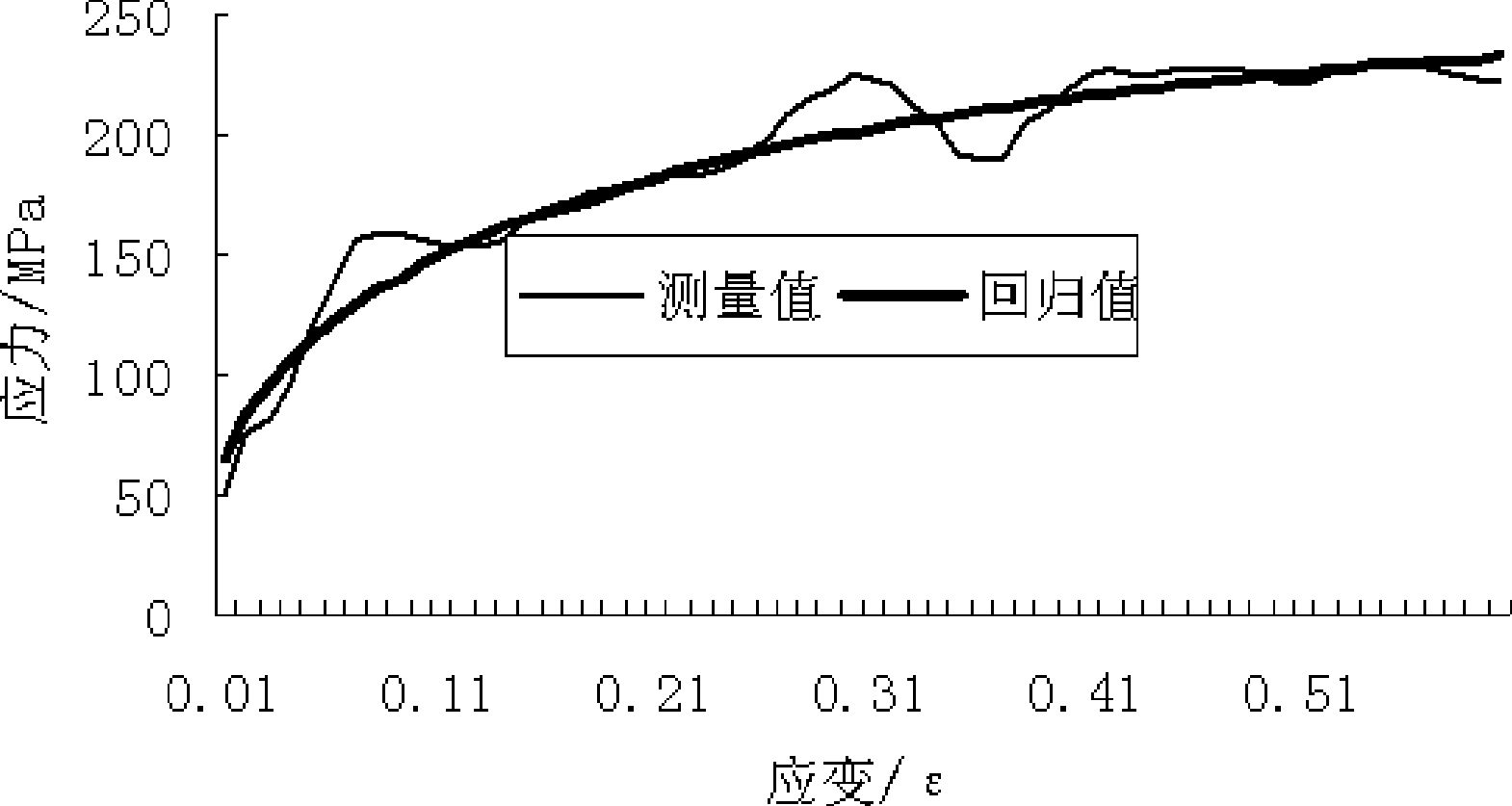

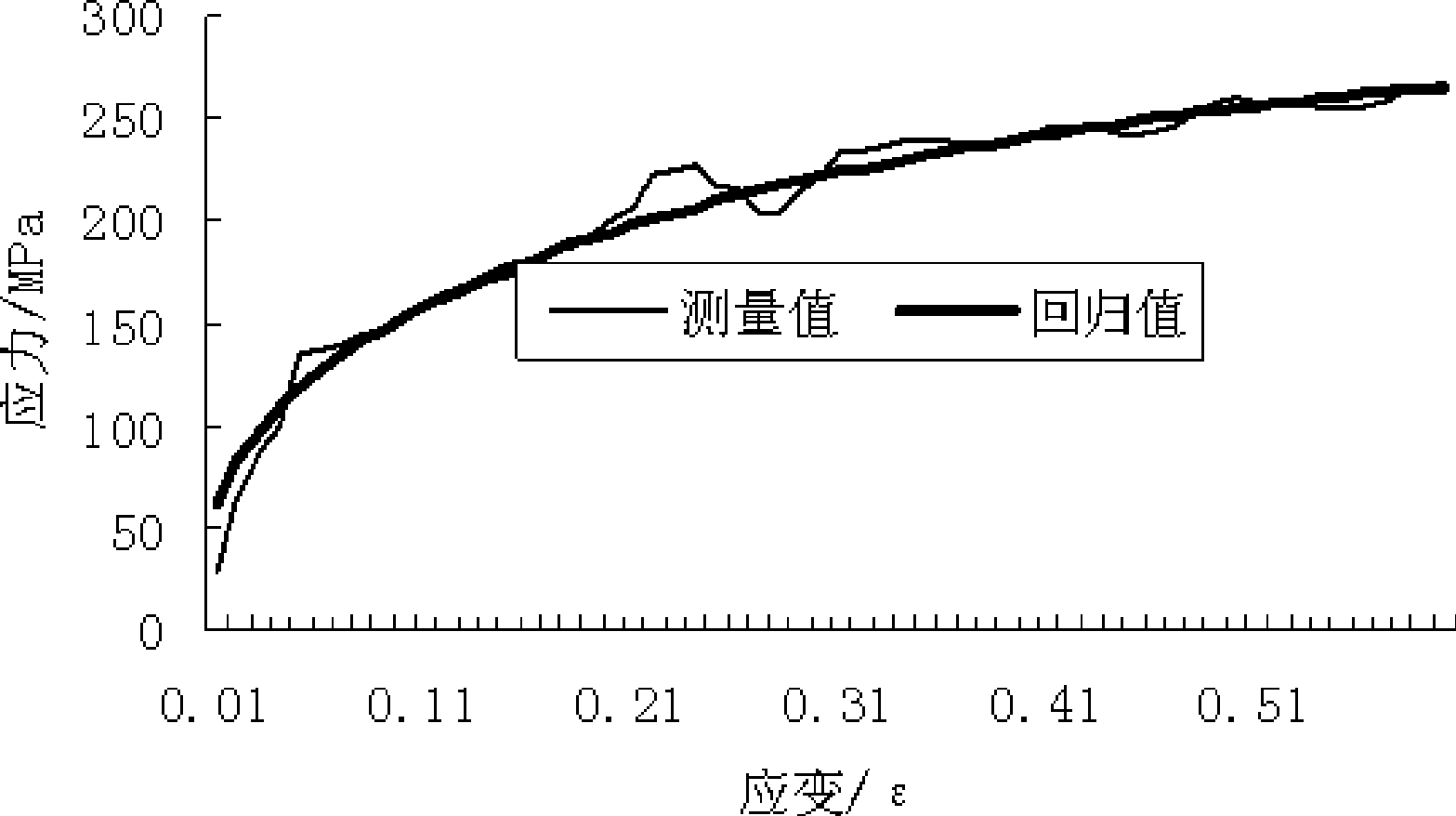

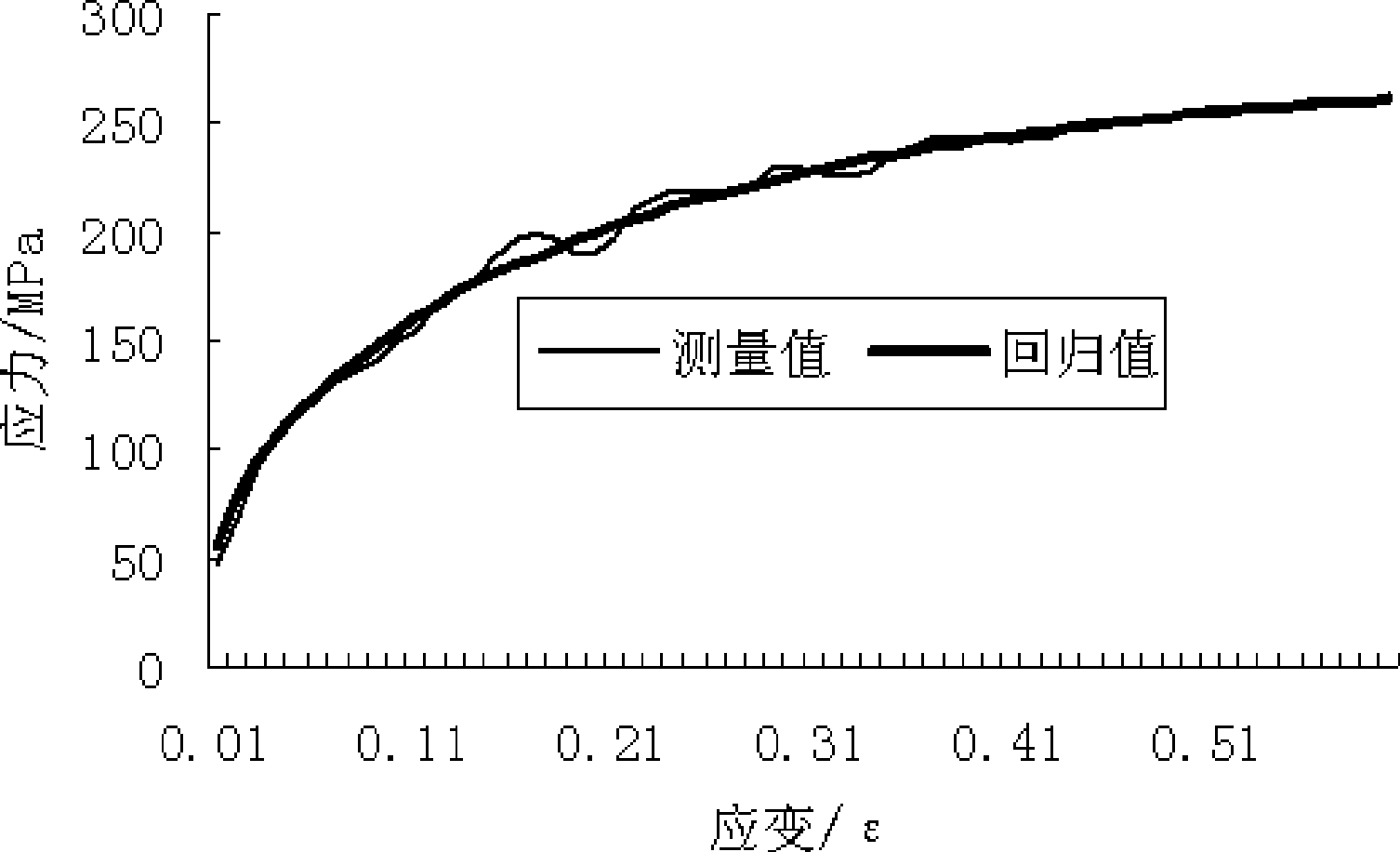

[0053] Such as Figure 1 ~ Figure 1 As shown in 1, the present invention is a method for controlling the rolling of medium and low grade electrical steels based on conventional rolling models.

[0054]First of all, the relationship between deformation temperature and deformation resistance of medium and low-grade electrical steel is studied through experiments, and the corresponding test data are obtained. According to the test data, the main influencing factors of the deformation resistance of electrical steel are analyzed, and finally the relationship curve between deformation resistance and temperature is drawn to provide the basic data for establishing the correction algorithm of the rolling model of electrical steel.

[0055] The deformation resistance curve test was completed on the Gleeble-3500 thermal / mechanical simulation testing machine. The testing machine can accurately simulate the thermal processing state of metal materials and accurately measure and record vari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com