Aluminium-clad steel strip for coolers and preparation method thereof as well as steel strip and aluminium alloy strip used thereby

A technology of aluminum-coated steel strips and aluminum alloy strips, applied in chemical instruments and methods, manufacturing tools, welding equipment, etc., can solve problems such as inclusions in composite layers, inability to apply brazing technology, formation, etc., and achieve excellent mechanical performance indicators Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

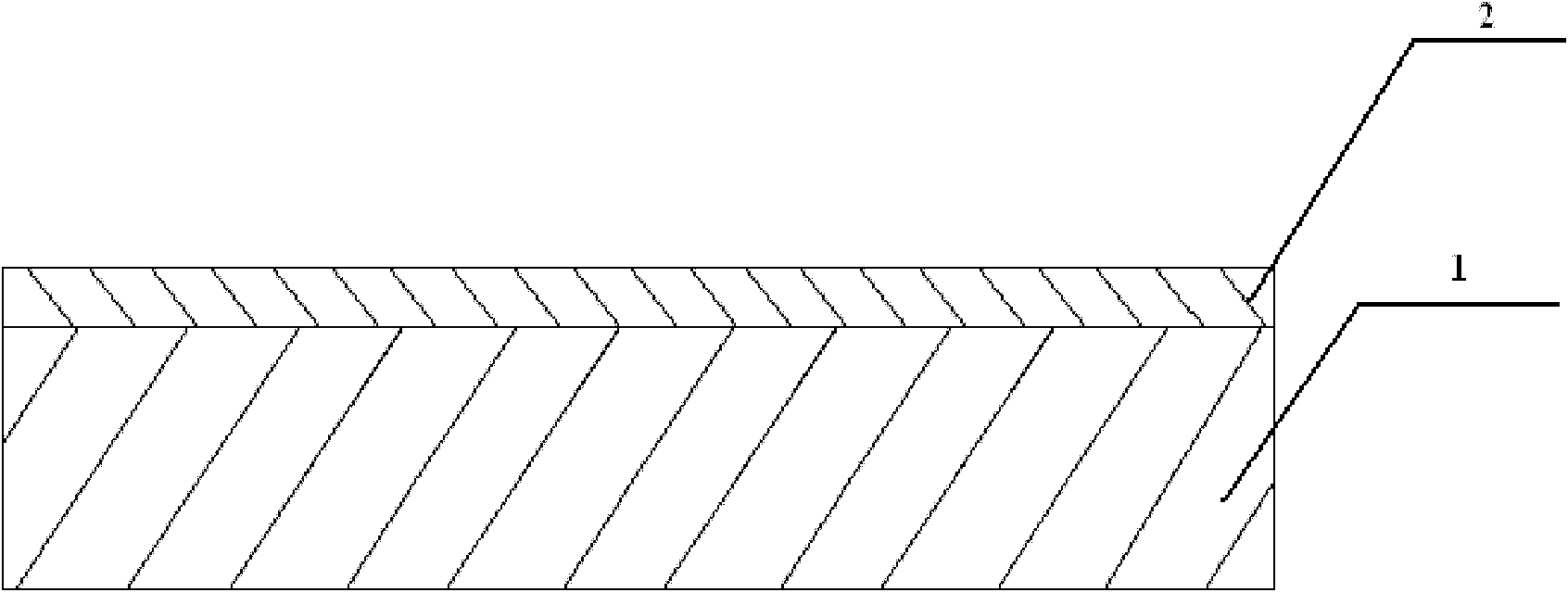

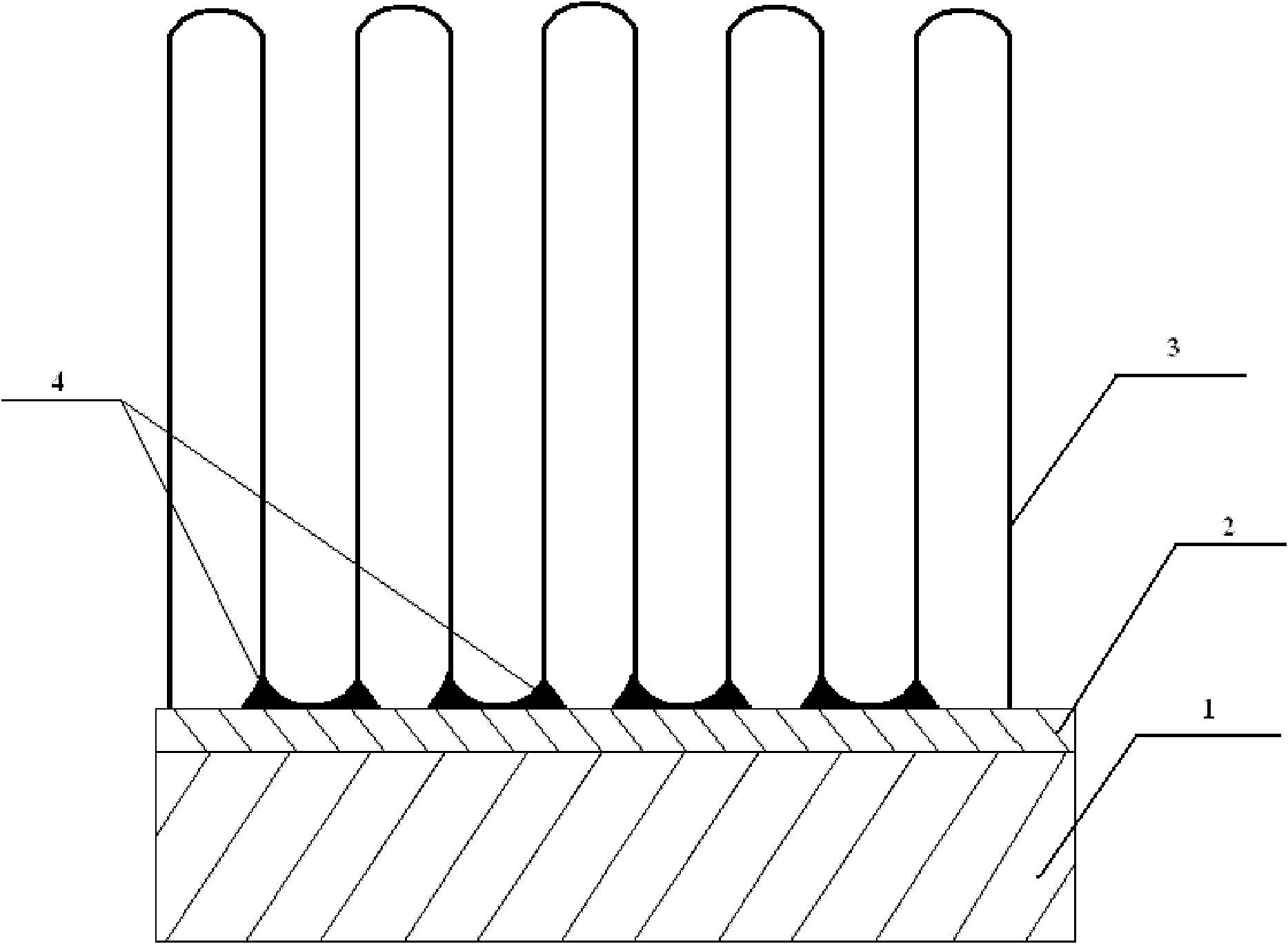

[0013] Specific implementation mode one: combine figure 1 with figure 2 Illustrate this embodiment, the aluminum clad steel strip of this embodiment cooler is made of steel strip 1 and aluminum alloy strip 2 cladding; The content of C in the described steel strip is less than 0.01% (weight), the content of Si is less than 0.01% (weight) ), the content of Mn is 0.20% to 0.30% (weight) and the content of Alt is less than 0.005% (weight); the content of Si in the aluminum alloy strip is 0.70% to 0.90% (weight) and the content of Fe is 0.30% ~0.45% by weight.

[0014] In this embodiment, the main component of the steel strip is iron, and the main component of the aluminum alloy strip is aluminum.

[0015] The aluminum-clad steel strip for the cooler of this embodiment is tested, and the yield strength (Y.S) of the aluminum-clad steel strip for the cooler of this embodiment is ≥ 260MPa, the tensile strength (T.S) is 330-380MPa, and the elongation (EL)> 30% , and repeated bendin...

specific Embodiment approach 2

[0017] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the content of C in the described steel strip is 0.005% (weight), the content of Si is 0.005% (weight), and the content of Mn is 0.25% ( weight) and the content of Alt is 0.003% (weight); the content of Si in the aluminum alloy strip is 0.80% (weight) and the content of Fe is 0.40% (weight). Others are the same as the first embodiment.

specific Embodiment approach 3

[0018] Specific embodiment three: the difference between this embodiment and specific embodiment one is: the steel strip is composed of 0.005% C, 0.005% Si, 0.25% Mn, 0.003% Alt and the iron of the balance by weight percentage Composition: The aluminum alloy strip is composed of 0.80% Si, 0.40% Fe and the rest Al in weight percentage. Others are the same as the first embodiment.

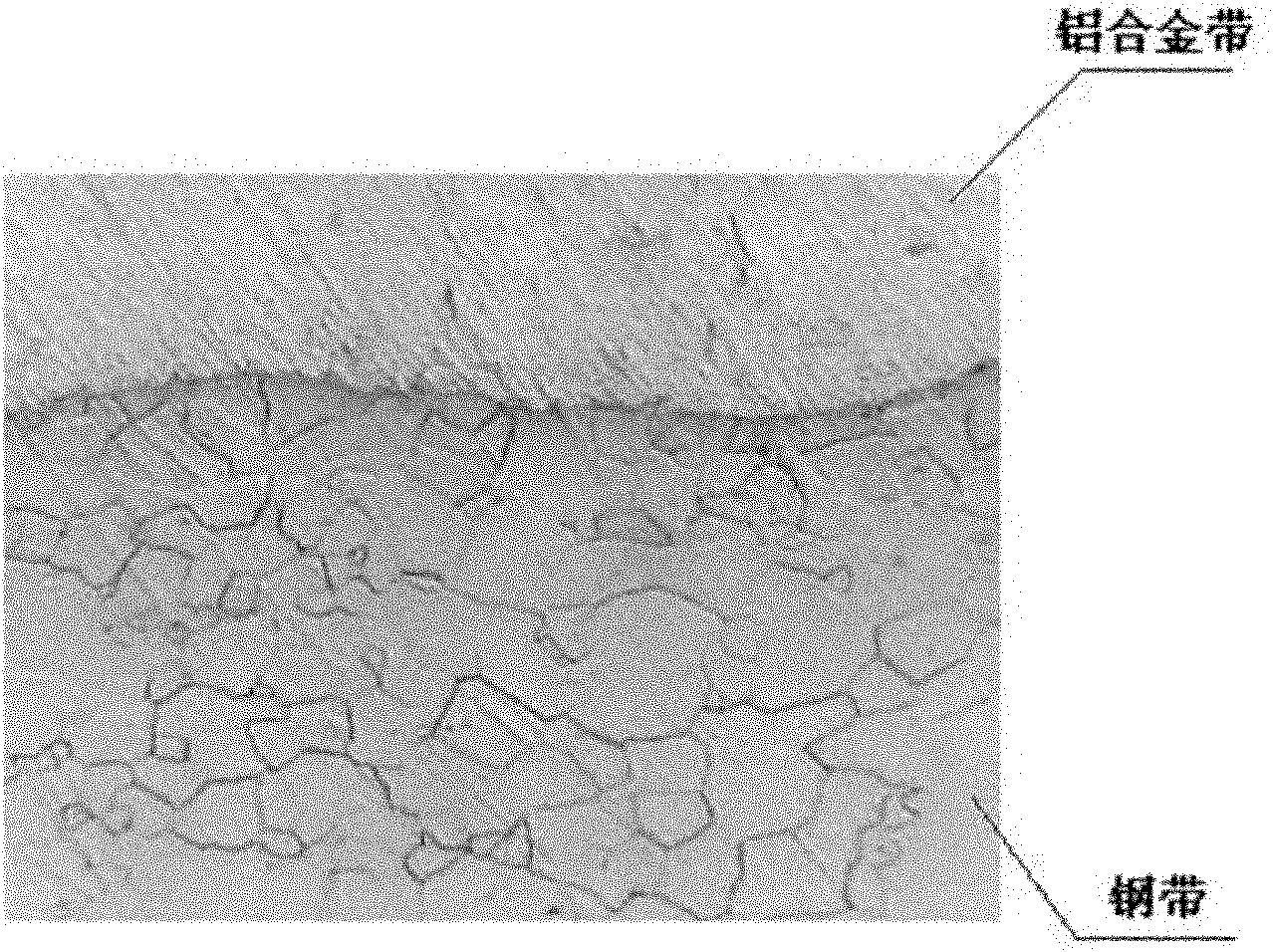

[0019] Figure 4 It is the two-dimensional phase analysis diagram of the X-ray diffraction micro-region of the steel-aluminum interface after brazing the fins of the cooler with an aluminum-clad steel strip for the cooler of this embodiment. The analysis result shows that there is no obvious metal transition layer between the steel and aluminum, and the interface Intermetallic compounds were also not formed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com