Heat preventing and insulating stealth compound material with broad-band wave absorption and preparation method thereof

A composite material and broadband technology, which is applied in the field of anti-heat insulation stealth composite materials and its preparation, can solve the problems of poor strength and adhesion of the heat insulation layer, and the inability to achieve effective bonding of aircraft metal bodies, etc., to achieve strong designability, High reliability and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

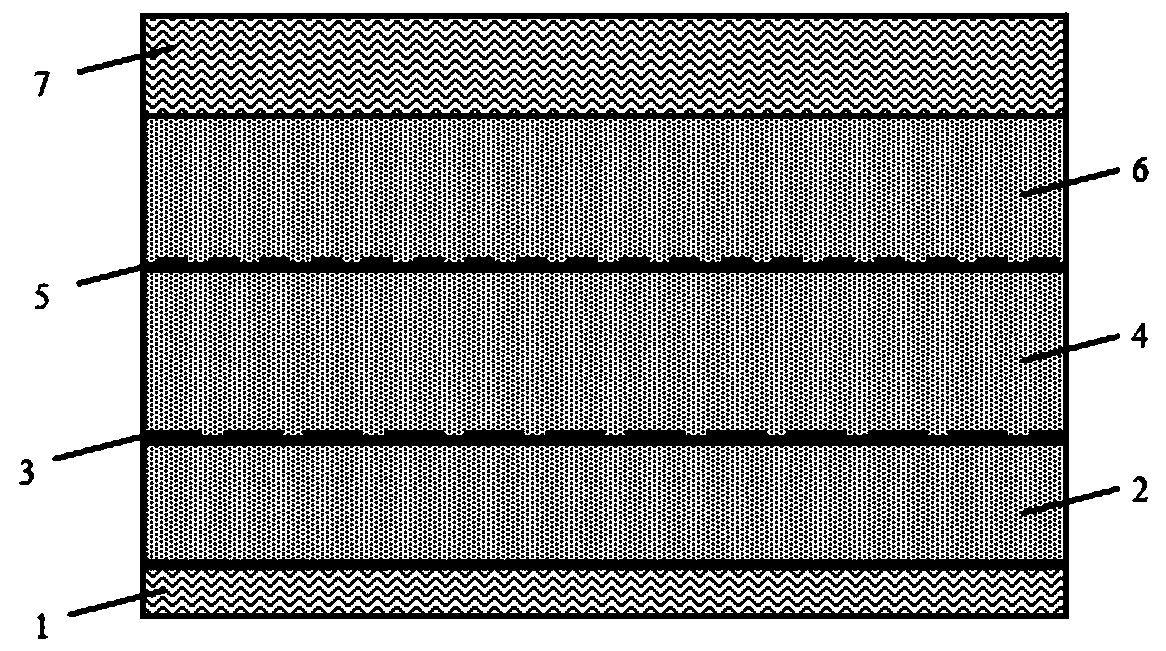

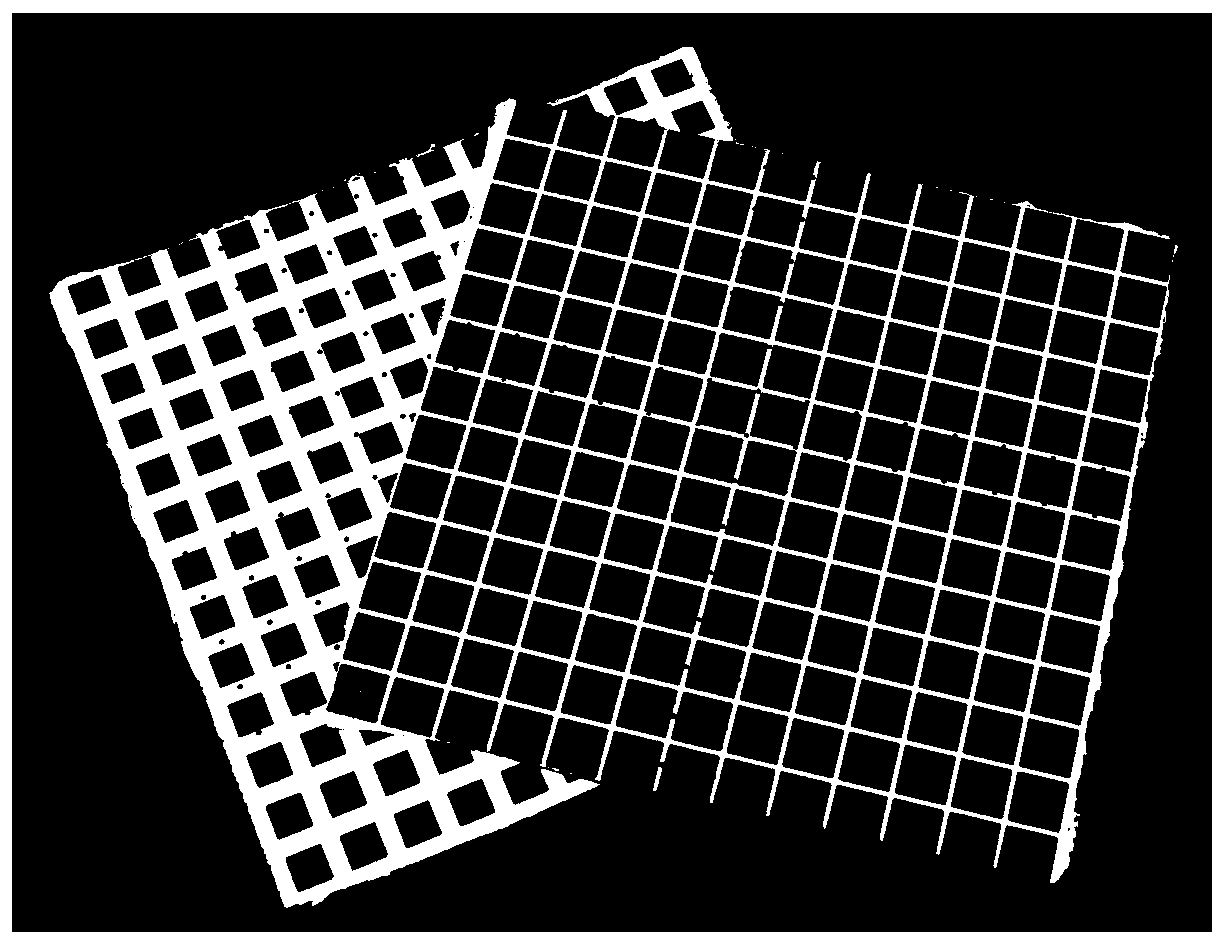

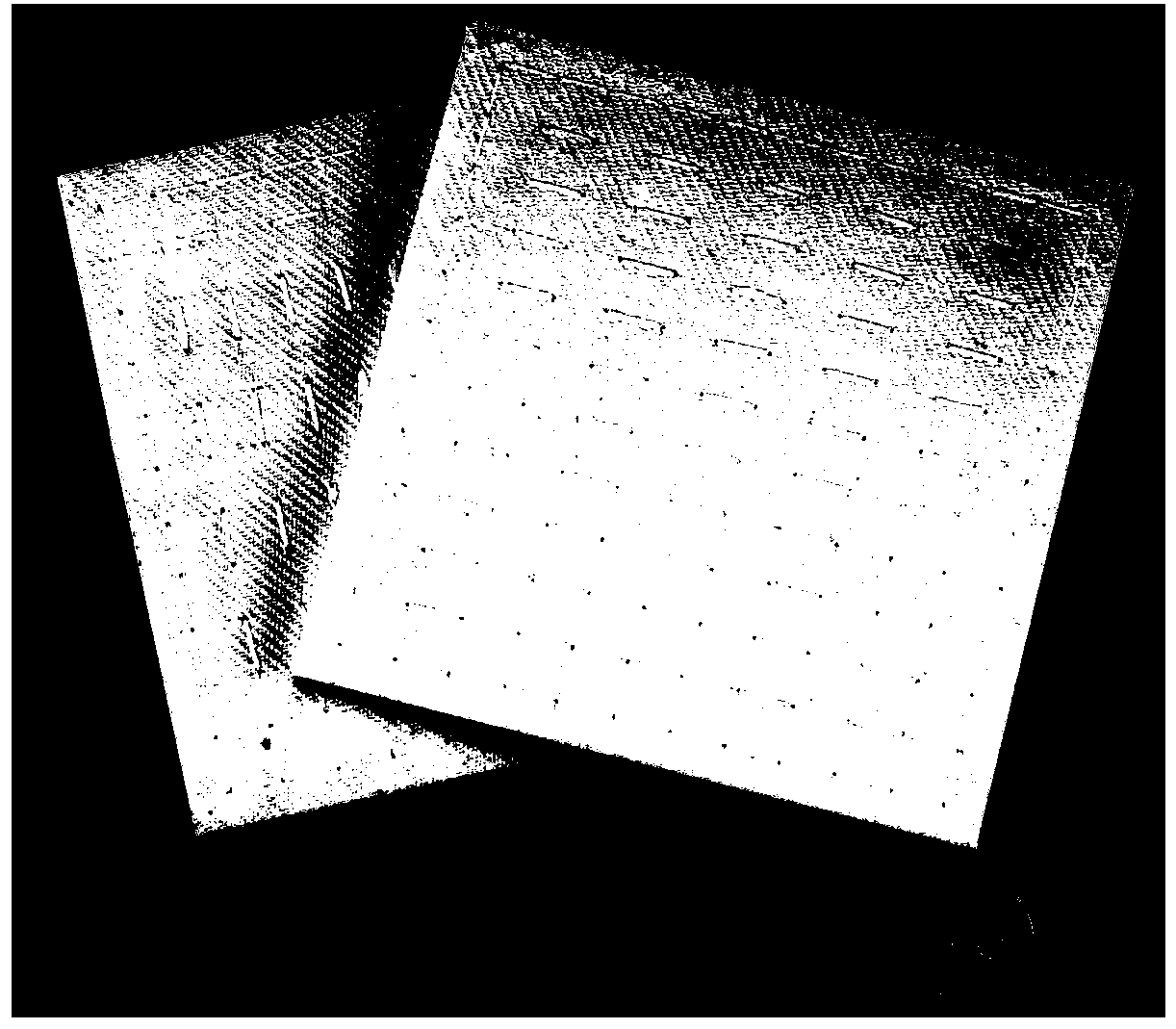

[0040] A kind of broadband wave-absorbing anti-heat insulation stealth composite material of the present invention, such as figure 1 As mentioned above, it includes the cold surface panel 1, the first airgel composite material insulation layer 2, the first resistance type high temperature metamaterial layer 3, the second airgel composite material insulation layer 4, and the second airgel composite material insulation layer from the inside to the outside. The resistive high-temperature metamaterial layer 5, the third airgel composite material insulation layer 6 and the thermal surface panel 7. The first airgel composite material insulation layer 2, the second airgel composite material insulation layer 4 and the third airgel composite material insulation layer 6 are all mullite ceramic fiber reinforced silica-oxidized Aluminum binary airgel composite material, the first resistive high-temperature metamaterial layer 3 and the second resistive high-temperature metamaterial layer 5...

Embodiment 2

[0053] A broadband wave-absorbing anti-heat insulation stealth composite material of the present invention, which sequentially includes a cold surface panel 1, a first airgel composite material insulation layer 2, a first resistance type high-temperature metamaterial layer 3, and a second Two airgel composite material insulation layers 4 , a second resistive high temperature metamaterial layer 5 , a third airgel composite material insulation layer 6 and a thermal surface panel 7 . The first airgel composite material heat insulation layer 2, the second airgel composite material heat insulation layer 4 and the third airgel composite material heat insulation layer 6 are all quartz ceramic fiber reinforced silica airgel composite material, the first resistive high-temperature metamaterial layer 3 and the second resistive high-temperature metamaterial layer 5 are prepared on a continuous quartz ceramic fiber-reinforced silicon oxide composite material with a thickness of 0.5mm, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com