Low temperature leadless welding material for electronic component

A technology for electronic components and lead-free soldering, which is applied in the field of lead-free solder paste, soldering process, and electronic products in the reflow soldering process. High thermal conductivity and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

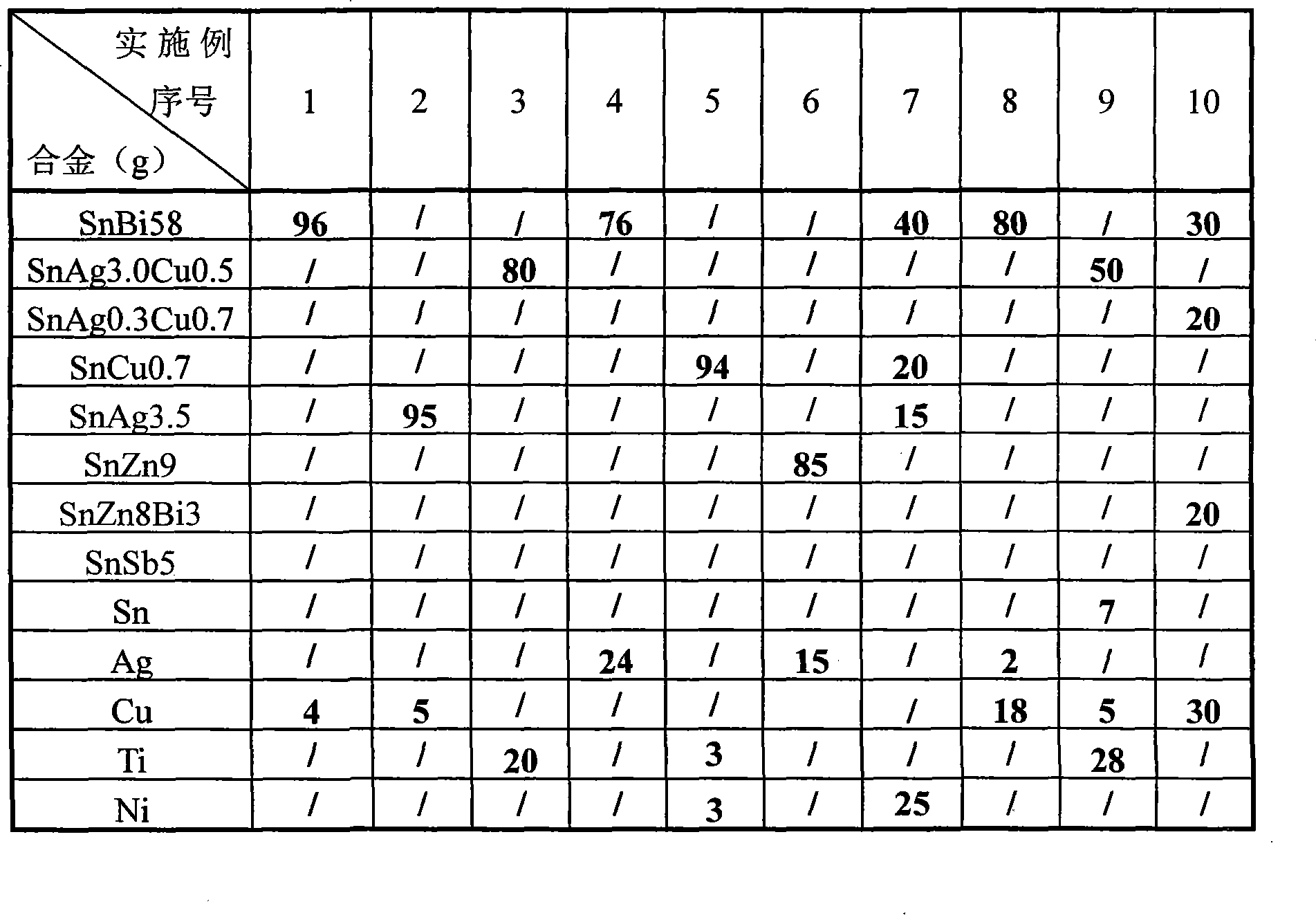

Embodiment 1

[0017] Example 1: Weigh 94g of SnBi58 powder with a particle size distribution of 25 μm to 75 μm and 6g of pure Cu powder, mix thoroughly, and then add rosin-type flux with a weight percentage of 12% of the solder material to make a solder paste. Apply solder paste on the surface of electronic components to be soldered, then place it in a reflow oven, adjust the heating curve, the peak temperature during the heating process is 200°C, and realize the connection between components.

Embodiment 2

[0018] Example 2: Weigh 95g of SnAg3.5 powder with a particle size distribution of 20μm-38μm and 5g of pure Cu powder, mix thoroughly, and then add rosin-type flux with a weight percentage of 12% of the solder material to make a solder paste. Apply solder paste on the surface of electronic components to be soldered, then place it in a reflow oven, adjust the heating curve, the peak temperature during the heating process is 250°C, and realize the connection between components.

Embodiment 3

[0019] Example 3: Weigh 80 g of SnAg3.0Cu0.5 powder with a particle size distribution of 25 μm to 45 μm and 20 g of pure Ti powder, mix thoroughly, and then add rosin-type flux with a weight percentage of 12% of the solder material to make a solder paste. Apply solder paste on the surface of the electronic components to be soldered, then place it in a reflow oven, adjust the heating curve, the peak temperature during the heating process is 240°C, and realize the connection between components.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com