Wet-type copper based powder metallurgy friction wafer and manufacturing method

A technology of powder metallurgy and manufacturing method, applied in the direction of friction lining, mechanical equipment, etc., can solve the problems of reducing the friction performance of the friction lining, affecting the appearance quality of the product, and increasing the energy consumption of the pressure transmission pad, so as to improve the coefficient of dynamic friction and size. The effect of reduced accuracy and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

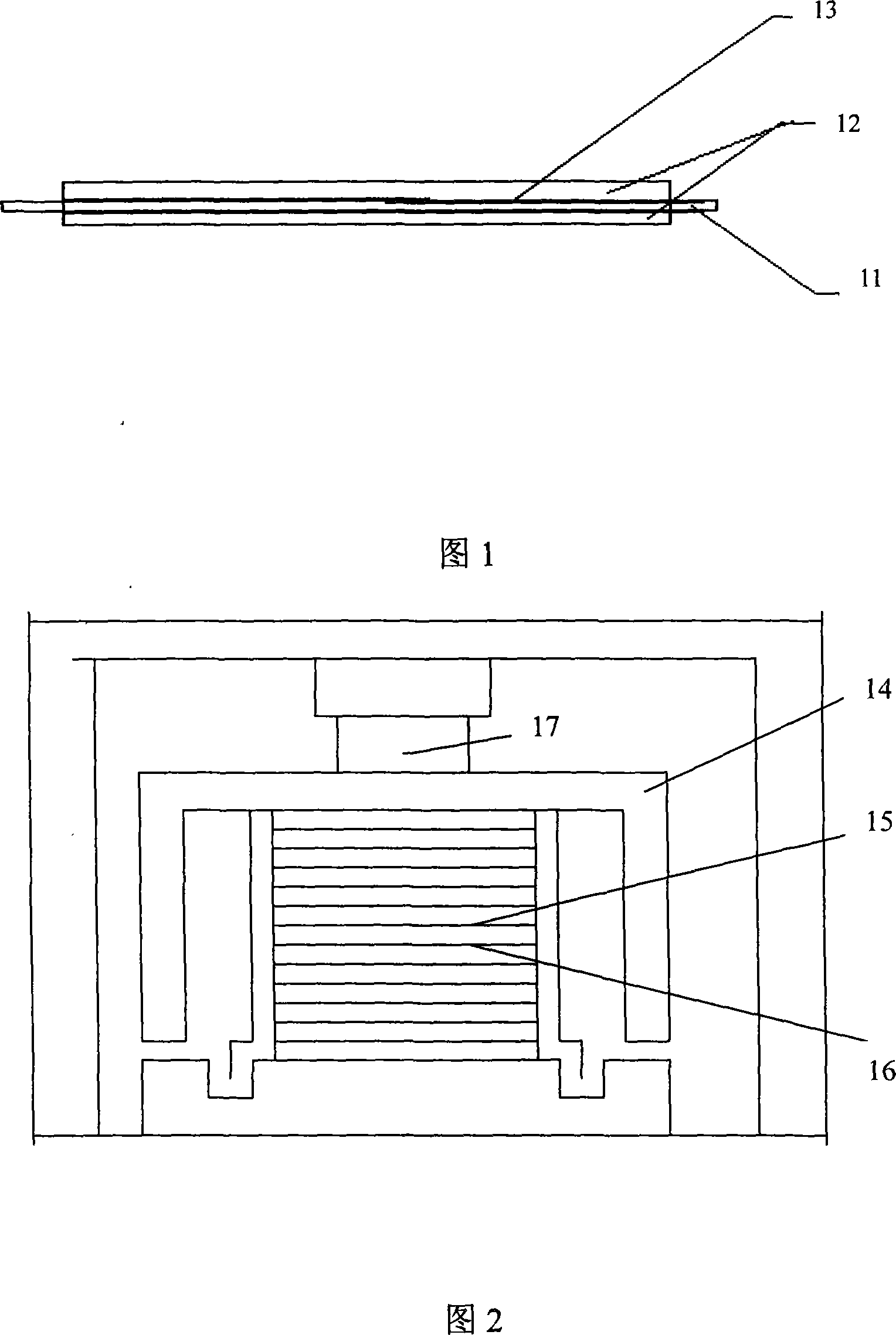

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings: as shown in accompanying drawing 3, the wet copper-based powder metallurgy friction plate of the present invention mainly consists of a steel core plate 21 in the middle and a friction layer 22 on at least one side, At least one side of the steel core plate 21 is combined with a layer of adhesive film 23 , and on the adhesive film layer 23 is compounded with a layer of friction layer 22 . The upper and lower sides of the steel core plate 21 shown in accompanying drawing 1 are respectively combined with a layer of adhesive film layer 23, and on the adhesive film layer 23, a layer of friction layer 22 is compounded respectively; and the pores in the friction layer 22 contain already Cured modified phenolic resin glue.

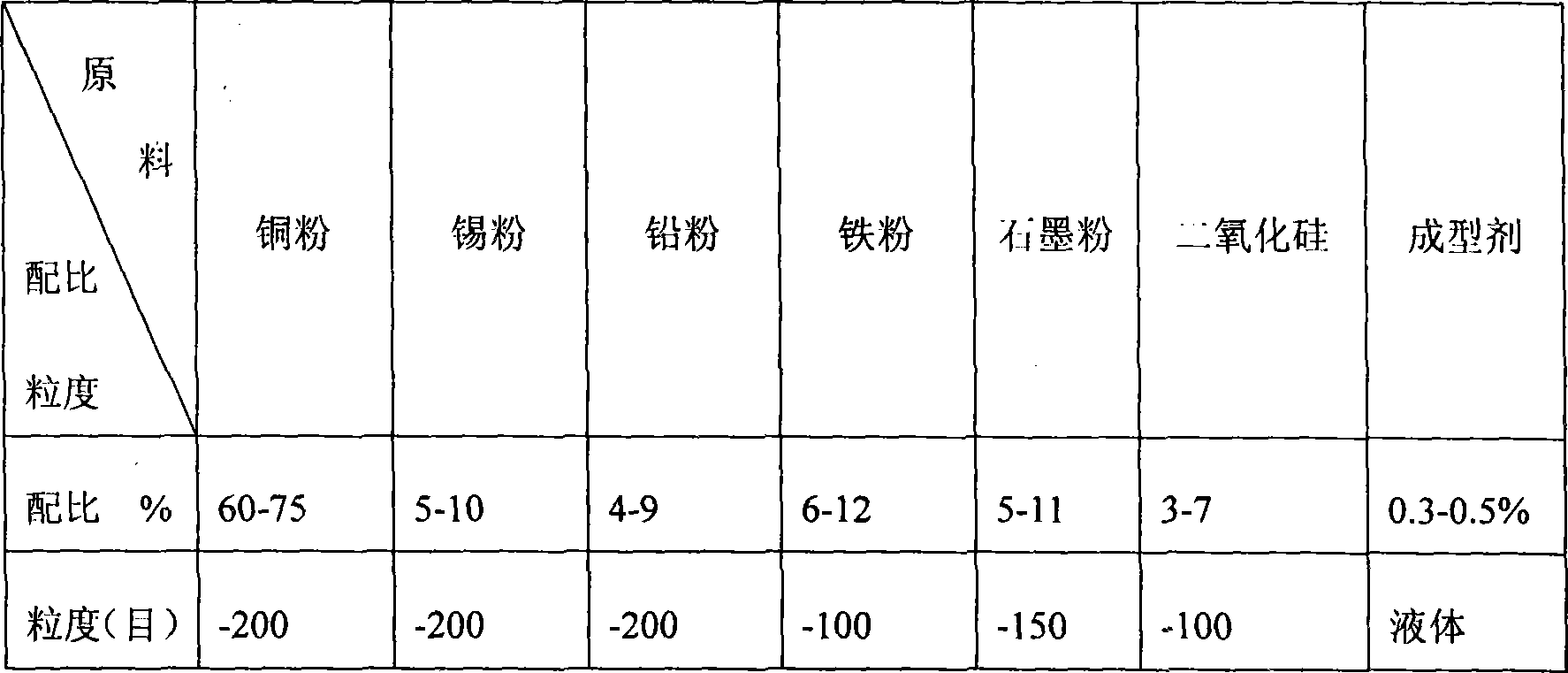

[0019] The manufacturing process of the wet copper-based powder metallurgy friction plate of the present invention is as follows: Friction layer ingredie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com