Organic light-emitting diode display

A luminescent and display technology, applied in the field of organic electroluminescent displays, can solve problems such as damage to organic functional layers, and achieve the effects of prolonging service life, reducing distance, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

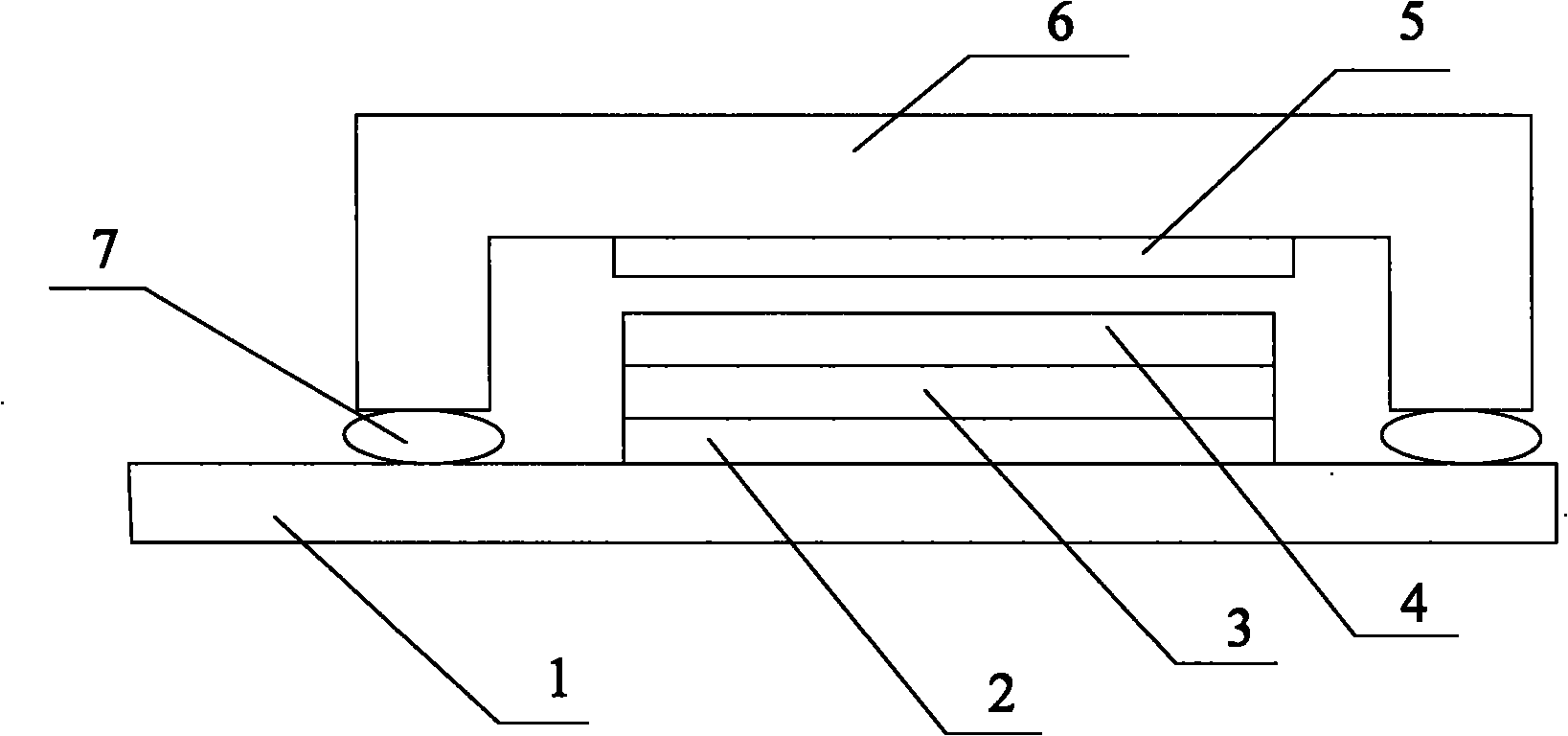

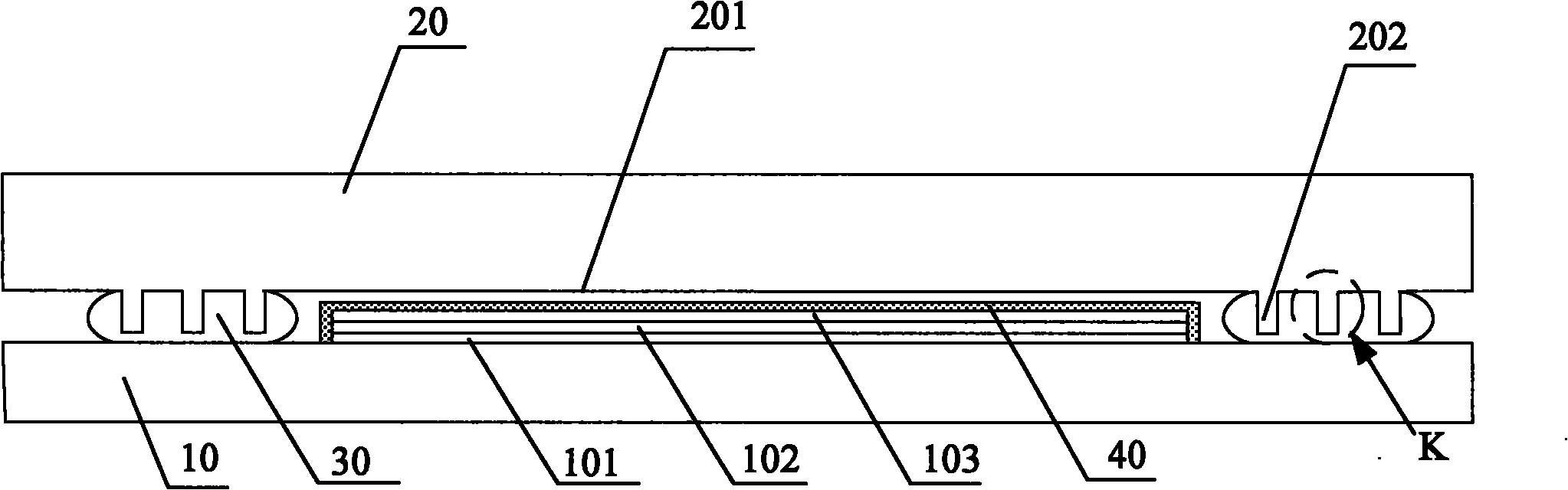

[0034] figure 2 is a schematic cross-sectional view of the OLED of the present invention. The invention provides an OLED, such as figure 2 As shown, the OLED includes: a substrate 10 , a back cover 20 , and an encapsulant 30 .

[0035] A pixel display area matrix is formed on the substrate 10; each pixel display area in the pixel display area matrix includes a transparent anode 101, an organic functional layer 102 and a cathode 103 deposited on the substrate 10 in sequence. The surface of each pixel display area is covered with a water-absorbing protective layer 40; if the special conductive glass is selected for use in the preparation of the substrate 10, the pre-deposited ITO (Indium Tin Oxide, indium tin oxide) coating on the conductive glass can be used as The anode of the OLED is used.

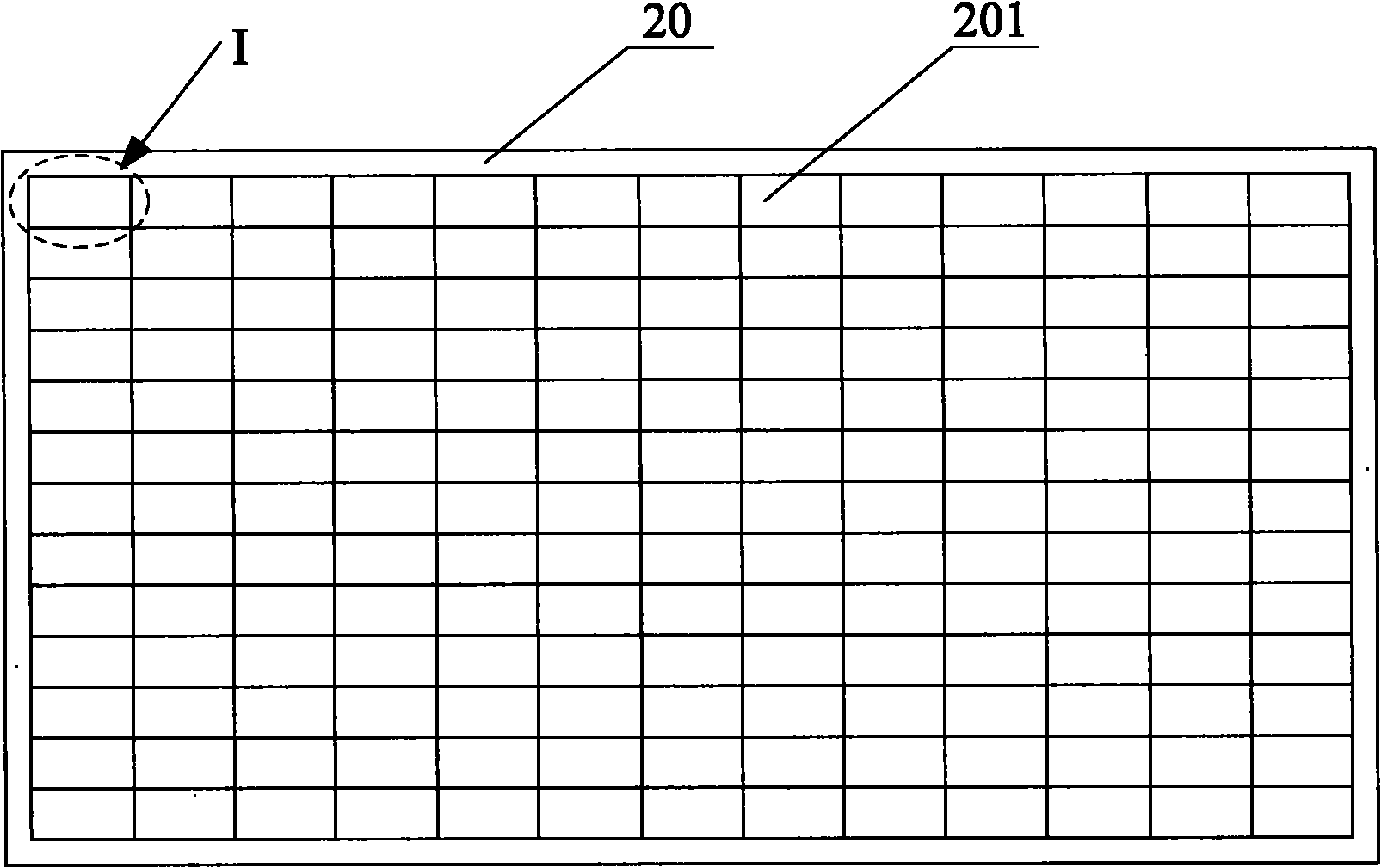

[0036] First, the rear cover of the present invention is introduced in detail. See also image 3 , Figure 4 ,in, image 3 It is a schematic bottom view of the rear cover glass...

Embodiment 2

[0053] The present embodiment provides the manufacturing method of the rear cover in the above-mentioned OLED, such as Figure 9 shown, including:

[0054] S10, forming a first pattern on a side of the rear cover glass facing the substrate.

[0055] After the back cover glass is selected, the regular polishing process will also be included. The back cover glass can be white glass with a thickness of 0.7 mm.

[0056] The first pattern covers the positions of the protrusions, and exposes the part between the light-emitting area and the protrusions. The forming of the first pattern on the back cover glass may be: spin coating photoresist on the side of the back cover glass facing the substrate, exposing and developing to form the first pattern. Wherein, the spin coating, exposure and development of the photoresist can be the same as the prior art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com