AB double-sided adhesive for low-residue electronic screens

A low-residue, double-sided adhesive technology, applied in the field of double-sided adhesive, can solve problems such as poor automatic defoaming ability, influence of light transmittance, and decreased performance of double-sided adhesive defoaming, so as to reduce the difficulty of lamination and improve automatic discharge. The effect of foaming ability and reducing the residual glue rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the embodiments, so that those skilled in the art can implement it with reference to the description.

[0019] This case lists an embodiment of low-residue electronic screen special AB double-sided adhesive tape, which is sequentially provided with a first release layer, a modified silica gel layer, a PET substrate layer, an optical adhesive layer and a second release layer from top to bottom. ; Wherein, the selection of the release layer and the PET substrate layer is a conventional choice, which can be selected from commercially available release materials and PET films.

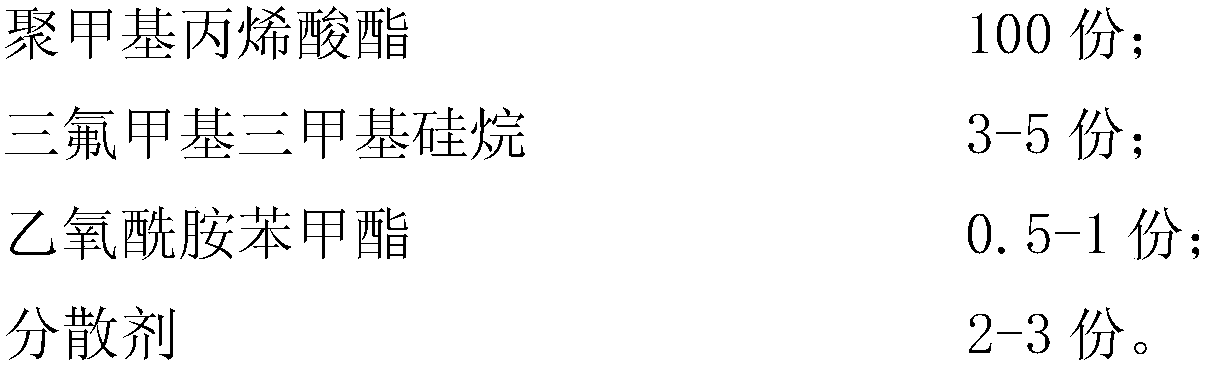

[0020] The modified silica gel layer includes the following materials by weight:

[0021]

[0022] The silica gel layer is mainly composed of polydimethylsiloxane, and aminosiloxane is used to synergistically improve the automatic defoaming ability of polydimethylsiloxane; sodium methyl silicate is used to improve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com