Curved screen and flat panel display module full-lamination method and integrated screen

A curved screen and flat display technology, applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve the problems of increasing lamination cost pressure, affecting lamination products, easy to generate air bubbles, etc., and achieve easy rework , Reduce the difficulty of lamination and the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

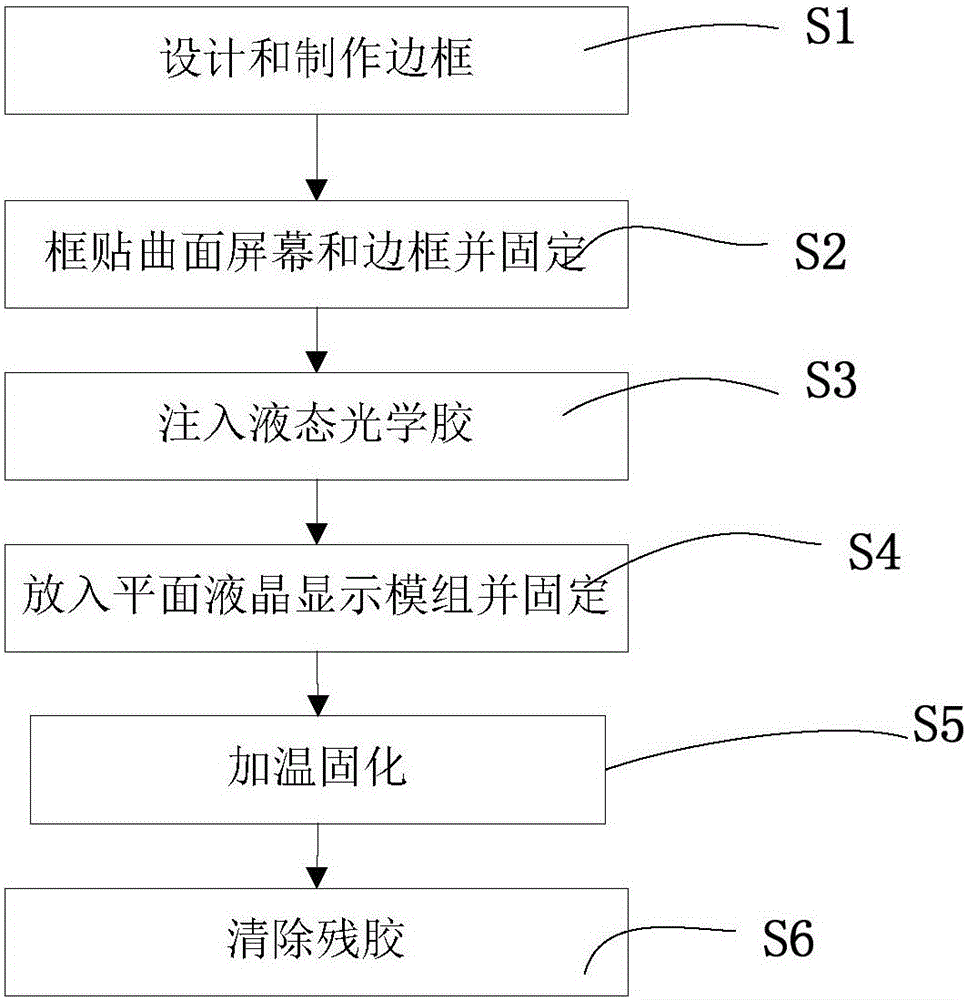

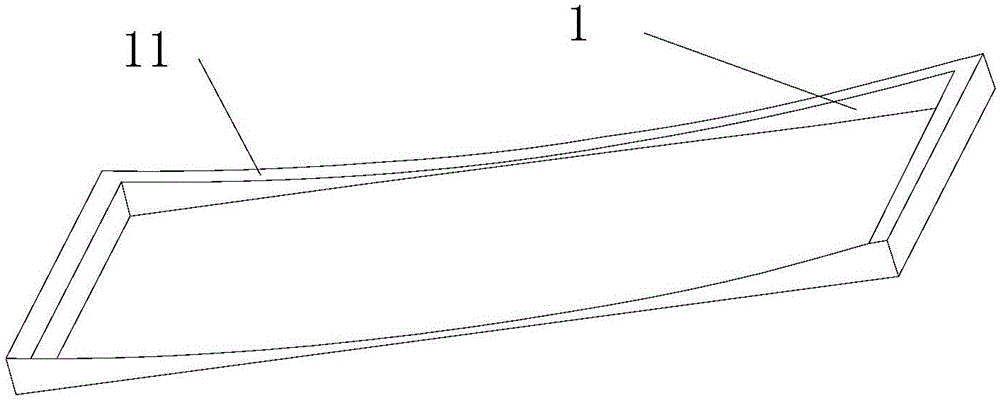

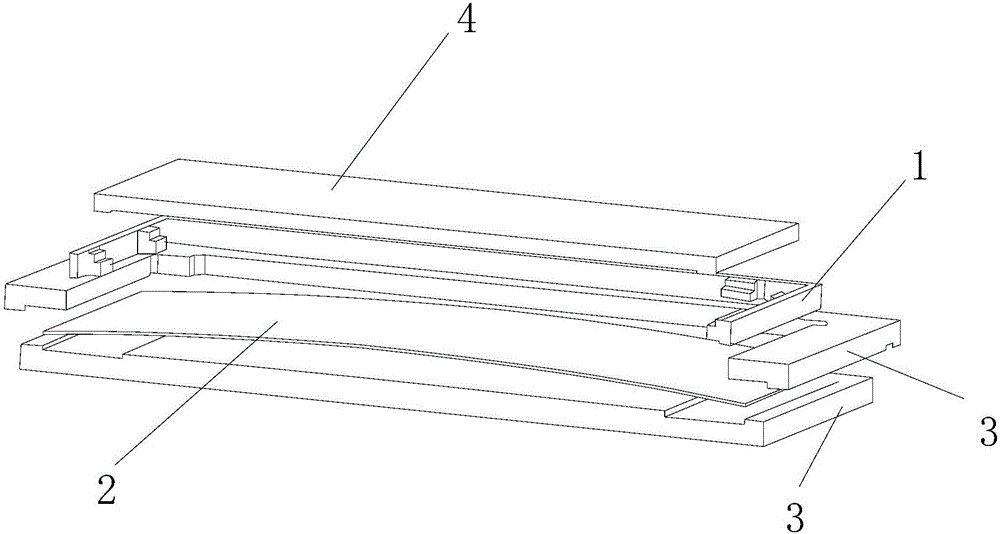

[0036] see figure 1 , figure 2 , image 3 and Figure 4 , the present invention provides a method for full bonding of a curved screen and a display module, including:

[0037] Designing and making a frame 1, comprising: the shape of the frame 1 is a square shape, the length and width of the frame 1 are greater than the height of the frame 1, the top surface of the frame 1 is a plane, and the frame 1 The bottom surface is an arc-shaped curved surface 11, the arc-shaped curved surface 11 has the same radius of curvature as the curved surface screen 2, and a double-sided adhesive tape is pasted on the arc-shaped curved surface 11;

[0038] Frame attaching the curved screen 2 and the frame 1 and fixing them with a positioning fixture 3 includes: removing the protective film of the double-sided tape, and pasting the curved screen 2 and the arc through the double-sided tape A curved surface 11, the frame 1 and the curved screen 2 form a groove; the frame 1 and the curved screen...

Embodiment 2

[0052] see figure 1 , figure 2 , image 3 and Figure 4 , the present invention provides a method for full bonding of a curved screen and a display module, including:

[0053] Designing and making a frame 1, comprising: the shape of the frame 1 is a square shape, the length and width of the frame 1 are greater than the height of the frame 1, the top surface of the frame 1 is a plane, and the frame 1 The bottom surface is an arc-shaped curved surface 11, the arc-shaped curved surface 11 has the same radius of curvature as the curved surface screen 2, and a double-sided adhesive tape is pasted on the arc-shaped curved surface 11;

[0054] Frame attaching the curved screen 2 and the frame 1 and fixing them with a positioning fixture 3 includes: removing the protective film of the double-sided tape, and pasting the curved screen 2 and the arc through the double-sided tape A curved surface 11, the frame 1 and the curved screen 2 form a groove; the frame 1 and the curved screen...

Embodiment 3

[0068] see figure 1 , figure 2 , image 3 and Figure 4 , the difference between this embodiment and Embodiment 1 is:

[0069] The processing technology is suitable for OGS full lamination, the curved screen 2 is a protective glass 21, the integrated screen adopts a single glass solution, and the inner surface of the protective glass 21 is provided with a contact implanted by etching. Control layer circuit.

[0070] Further, the heating device is a heating plate.

[0071] Further, the heating temperature of the heating plate is 60-80°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com