Patents

Literature

58 results about "Visual distortion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

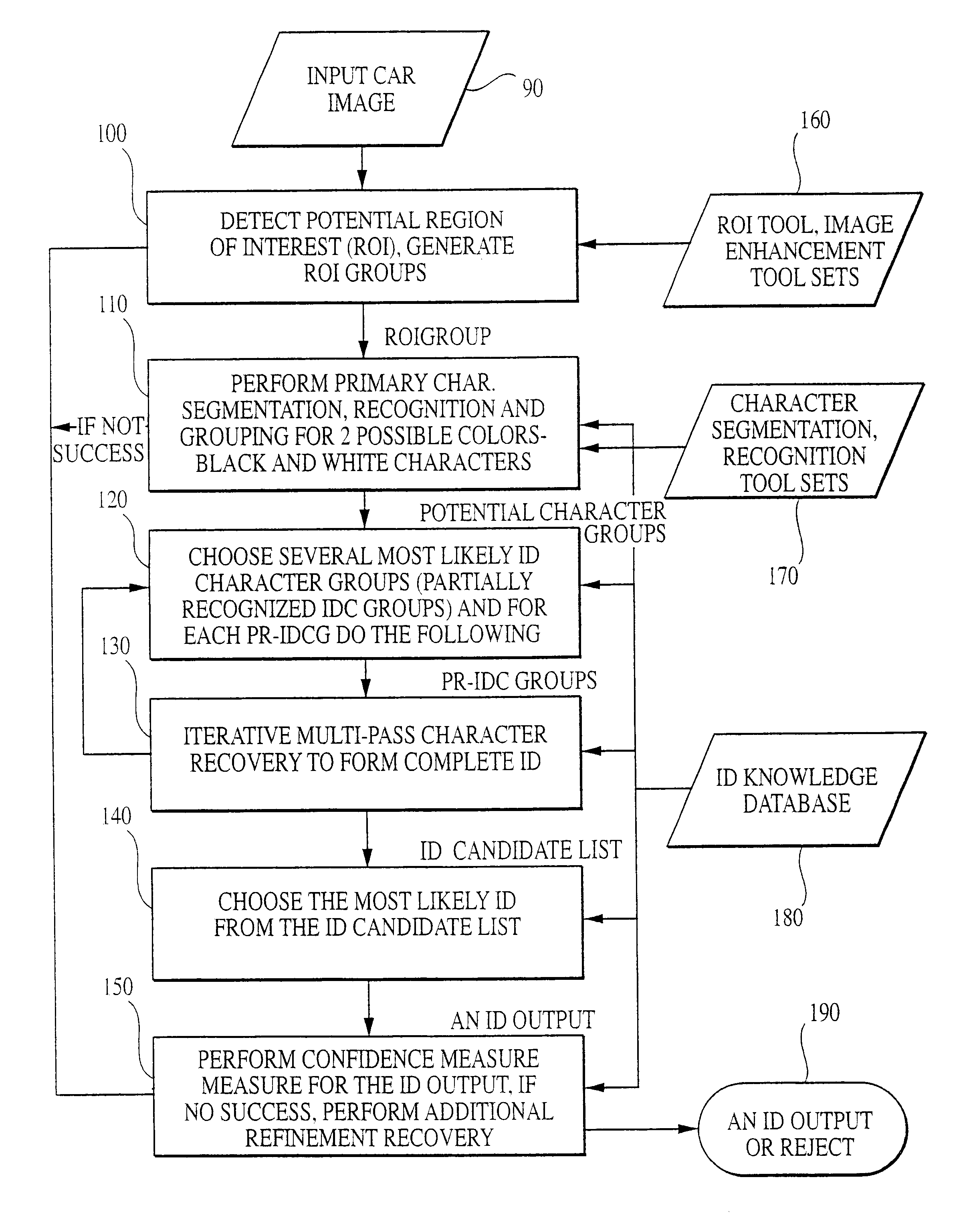

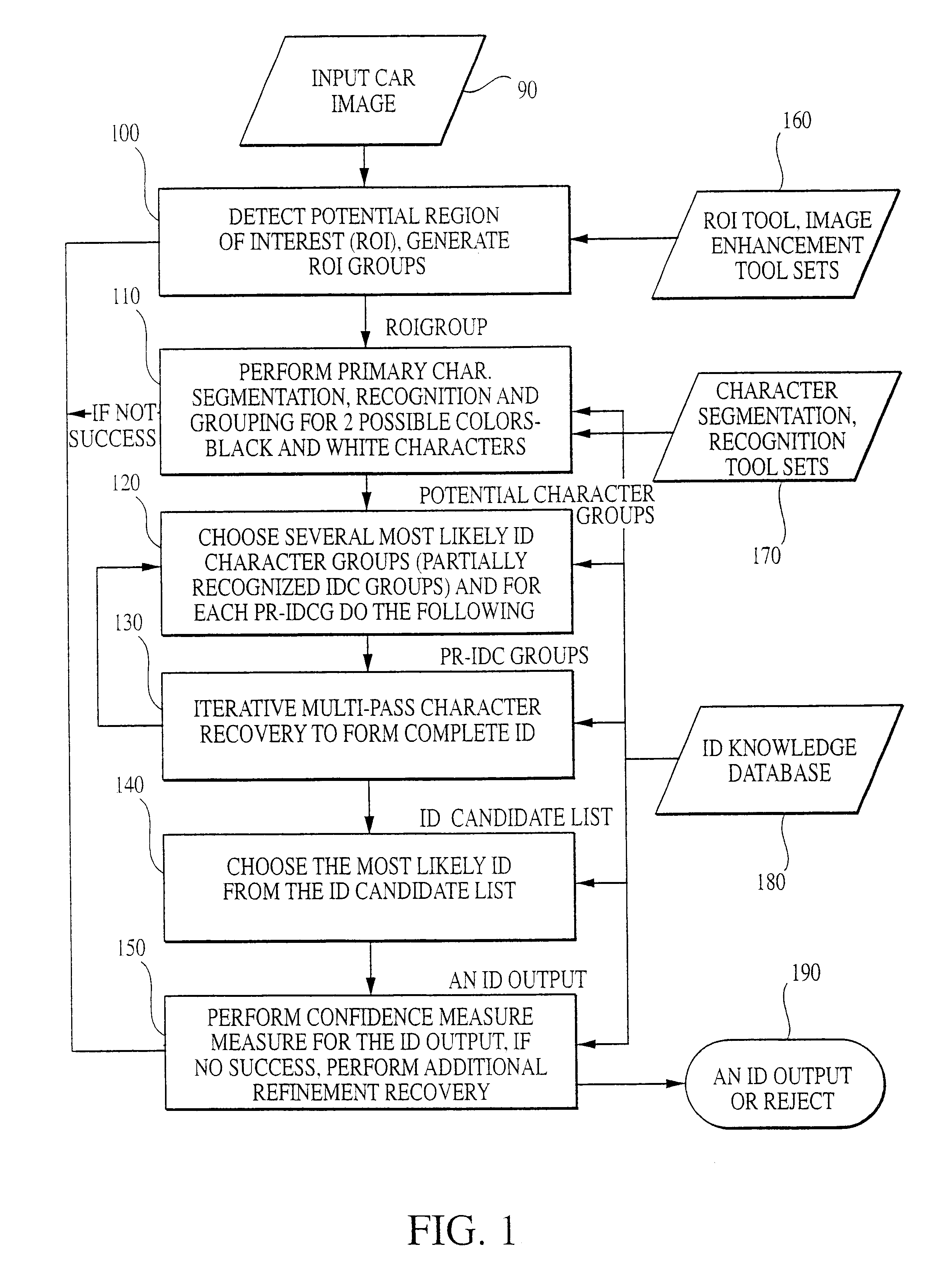

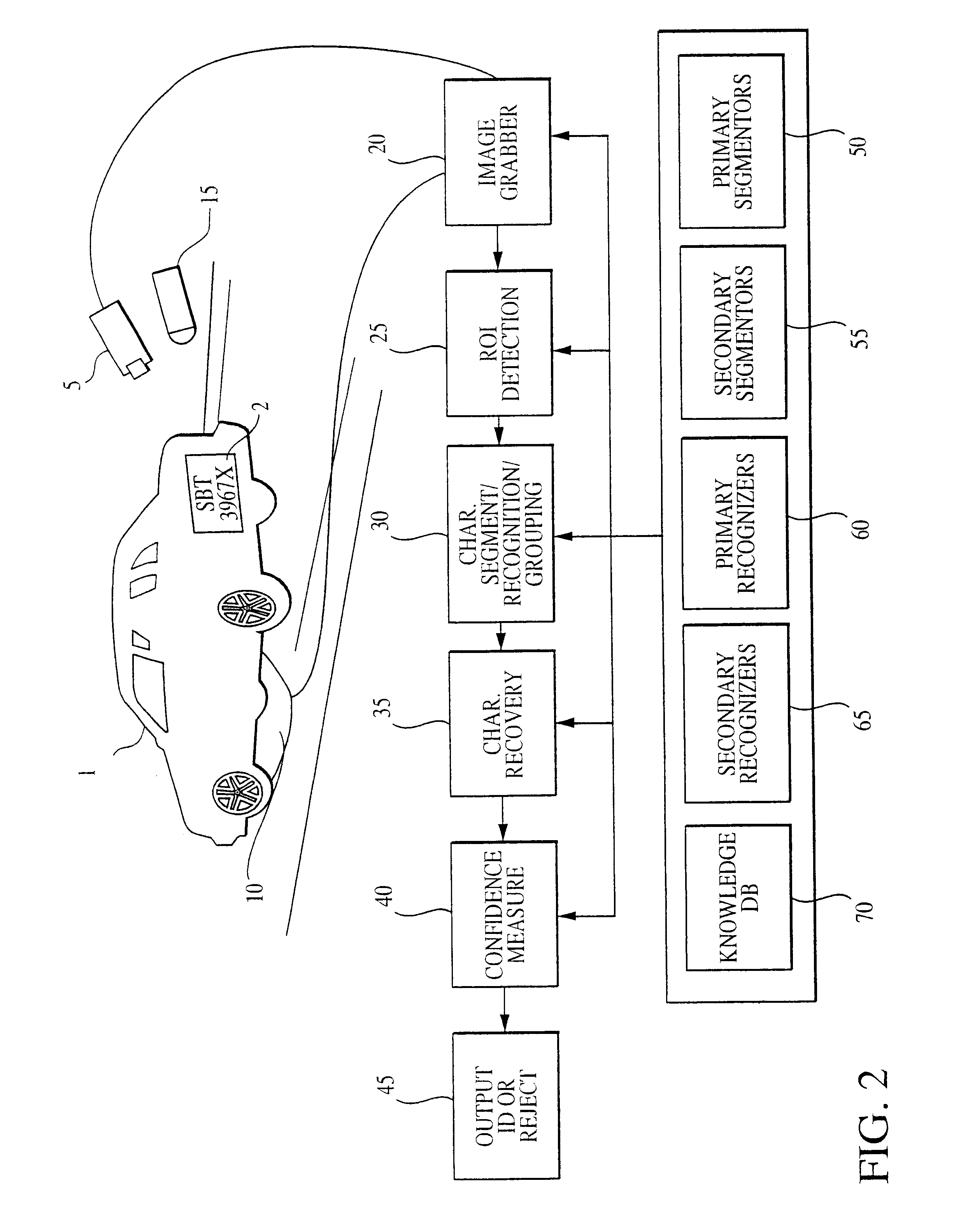

Robust identification code recognition system

InactiveUS6339651B1Improve accuracyEasy to findFrequency-division multiplex detailsDigital data processing detailsAlgorithmTheoretical computer science

A method and system for recognizing the characters on surfaces where alphanumeric identification code ("ID" for short) may be present such as a license plate. The present system is particularly adapted for situations where visual distortions can occur, and utilizes a highly robust method for recognizing the characters of an ID. Multiple character recovery schemes are applied to account for a variety of conditions to ensure high accuracy in identifying the ID. Accuracy is greatly enhanced by taking a comprehensive approach where multiple criteria are taken into consideration before any conclusions are drawn. Special considerations are given to recognizing the ID as a whole and not just the individual characters.

Owner:KENT RIDGE DIGITAL LABS +1

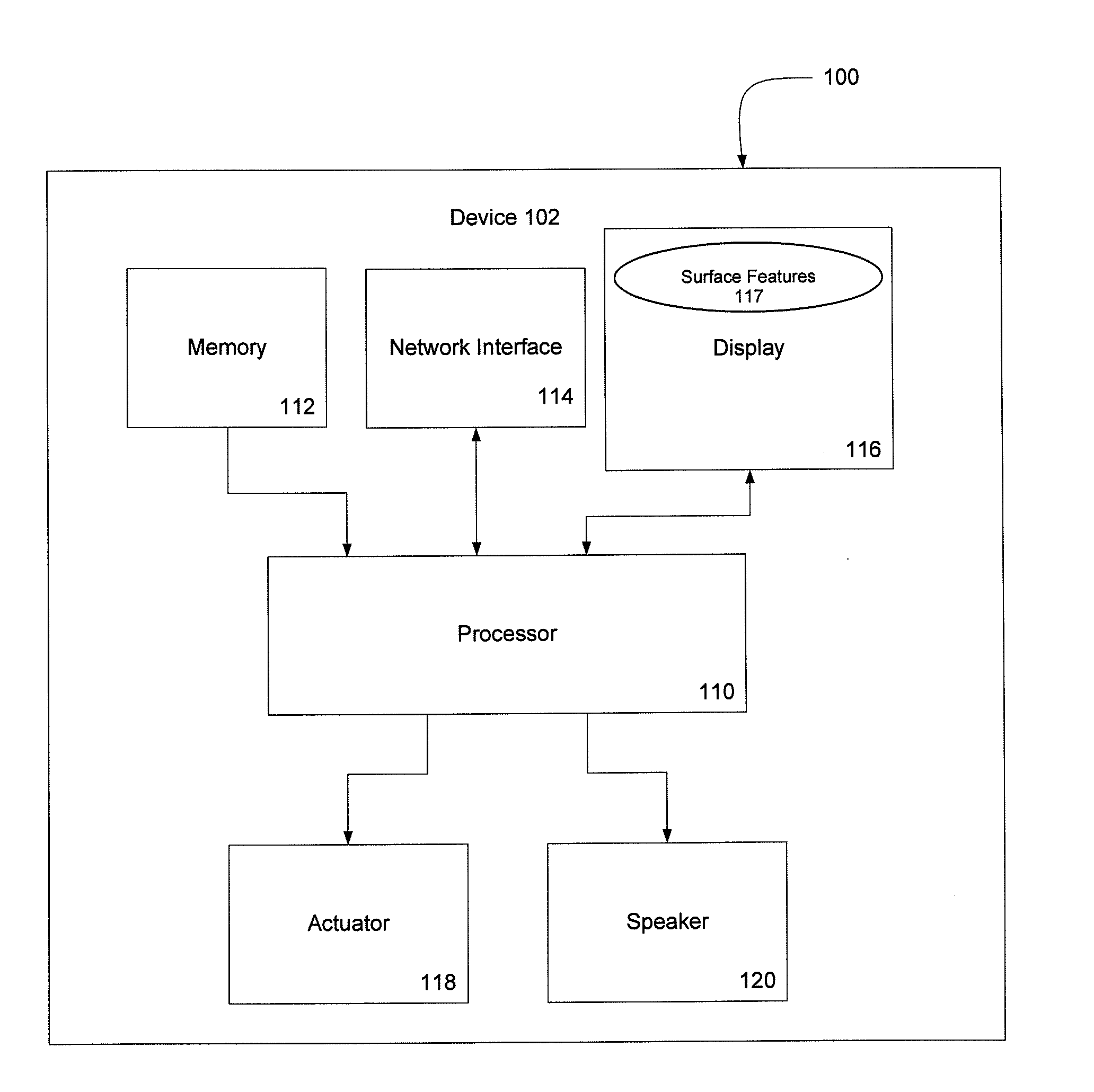

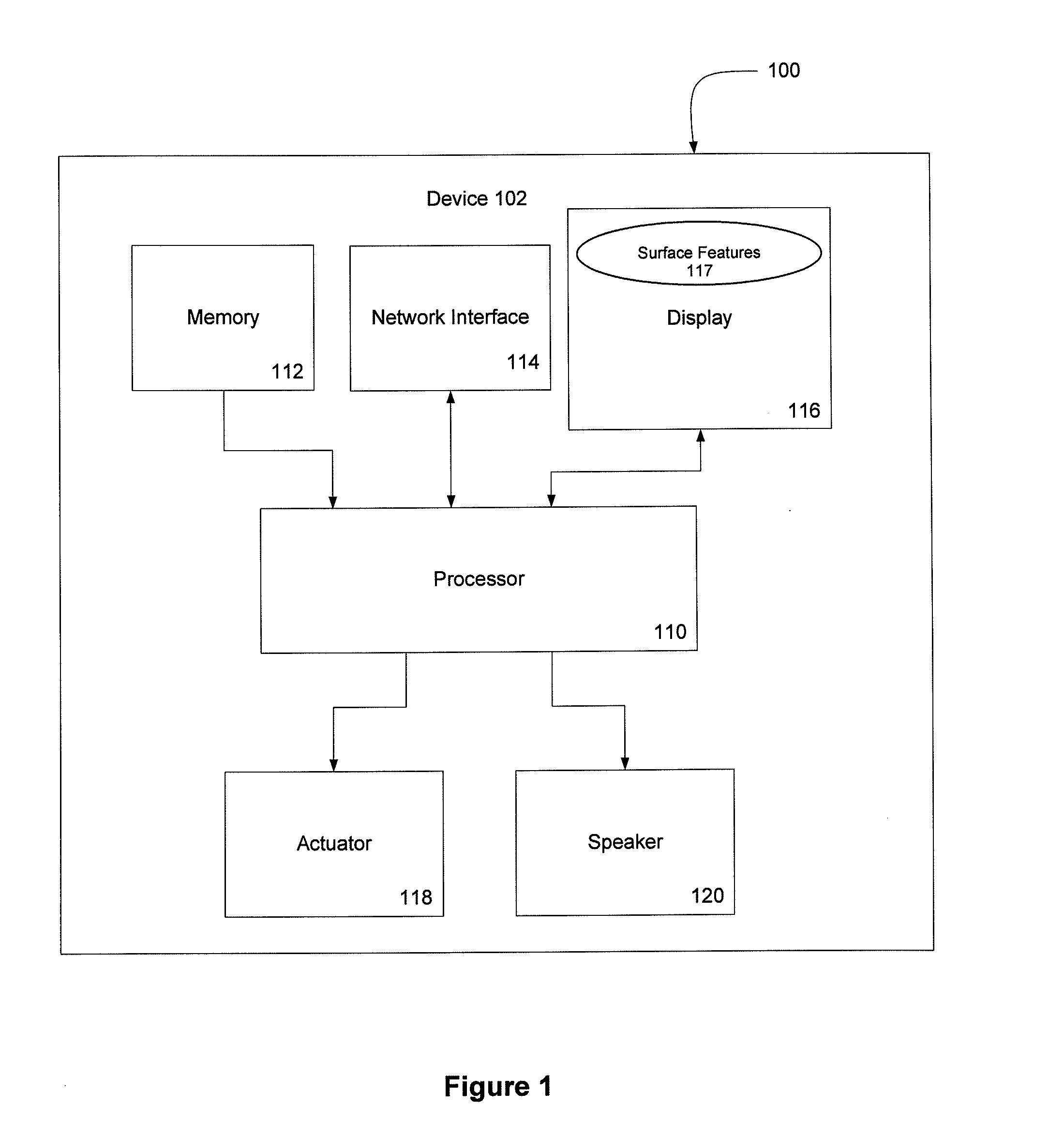

Systems and Methods For Compensating For Visual Distortion Caused By Surface Features On A Display

InactiveUS20110102462A1Compensation DistortionImage enhancementGeometric image transformationGraphicsDisplay device

Systems and methods for compensating for visual distortion caused by surface features on a display are disclosed. For example, one disclosed system includes: a display including one ore more surface features; a processor configured to: receive a display signal including graphical data; determine a location of the surface feature; transform the display signal based at least in part on the location of the surface feature; and cause the transformed display signal to be displayed.

Owner:IMMERSION CORPORATION

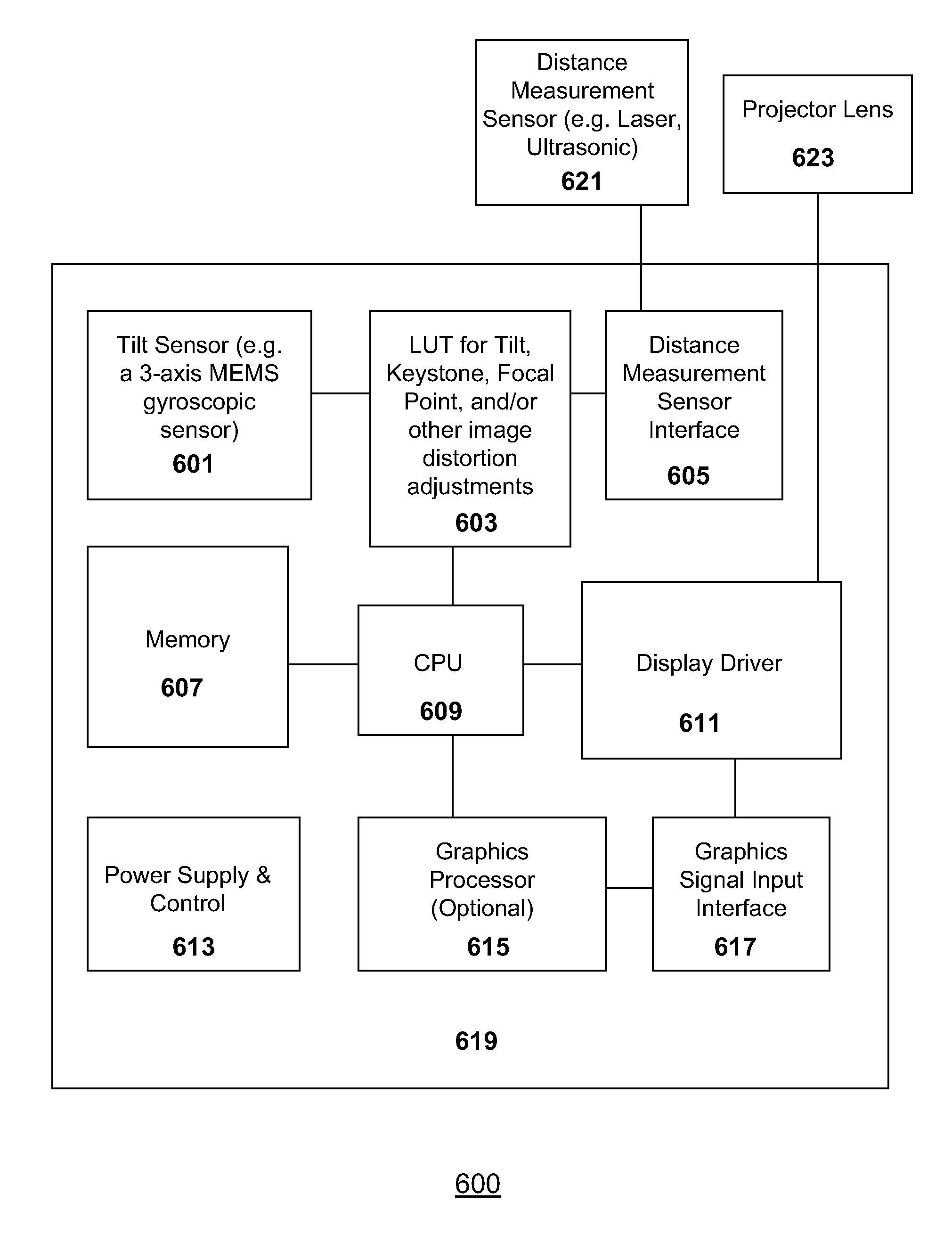

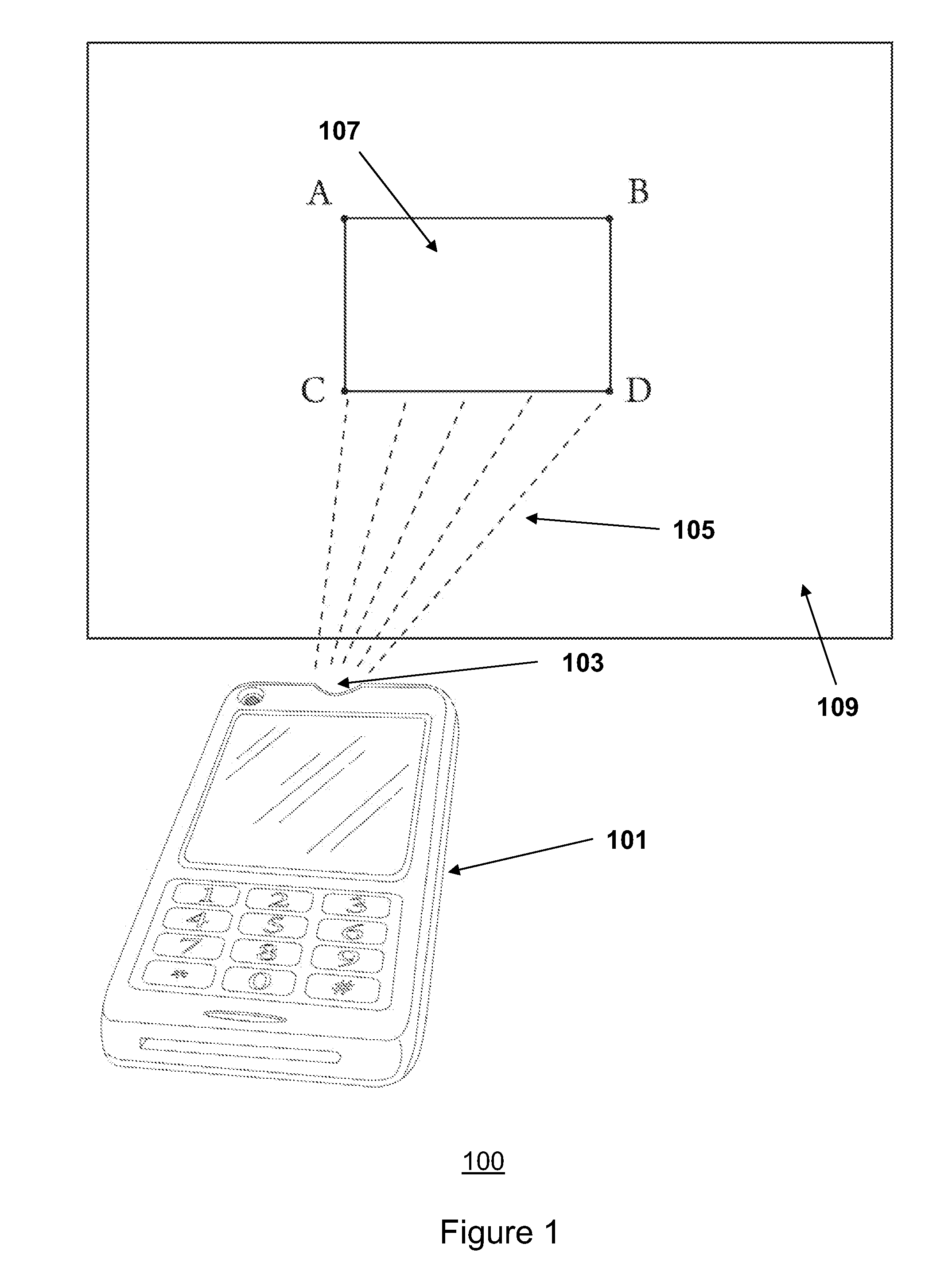

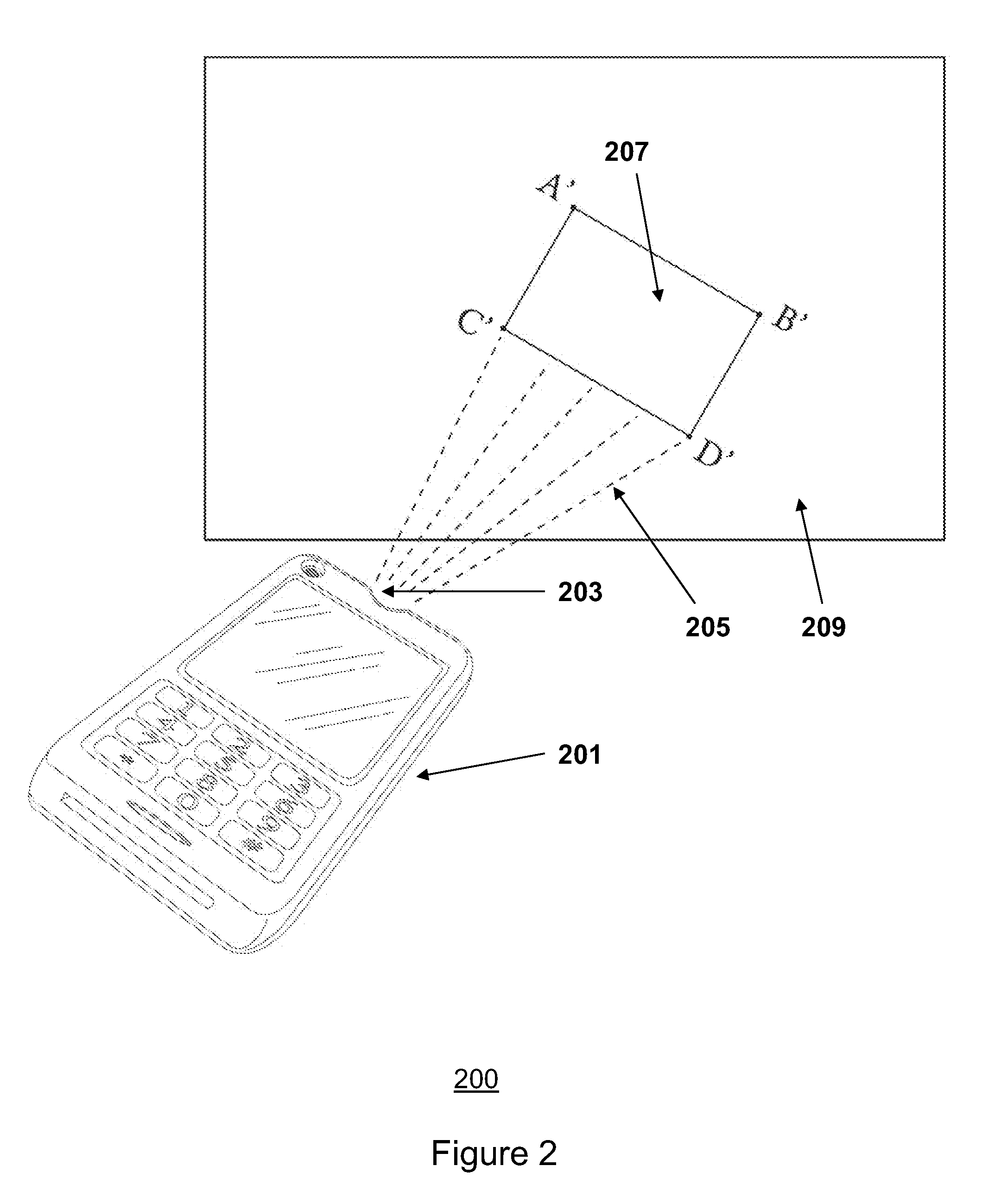

Apparatus and method for automated visual distortion adjustments for a portable projection device

An apparatus and a method are disclosed for automated projection image adjustments for a portable projection device. In one embodiment of the invention, the apparatus periodically polls a tilt sensor inside the portable projection device and uses the tilt sensor reading as a key to a lookup table which stores pre-computed visual distortion adjustment values. Furthermore, the apparatus can also poll a distance measurement sensor to measure a distance between a projector lens and a presumed projection surface periodically. The measured distance value can also be used as an additional parameter to the key for the lookup table to retrieve appropriate visual distortion adjustment values which are pre-computed and stored in the lookup table. The fast pre-computed adjustment value retrieval without real-time computation of graphical transformations to correct the visual distortions minimizes processor load, energy consumption, and processing delays for projection image corrections.

Owner:CHO SAMUEL SEUNGMIN +1

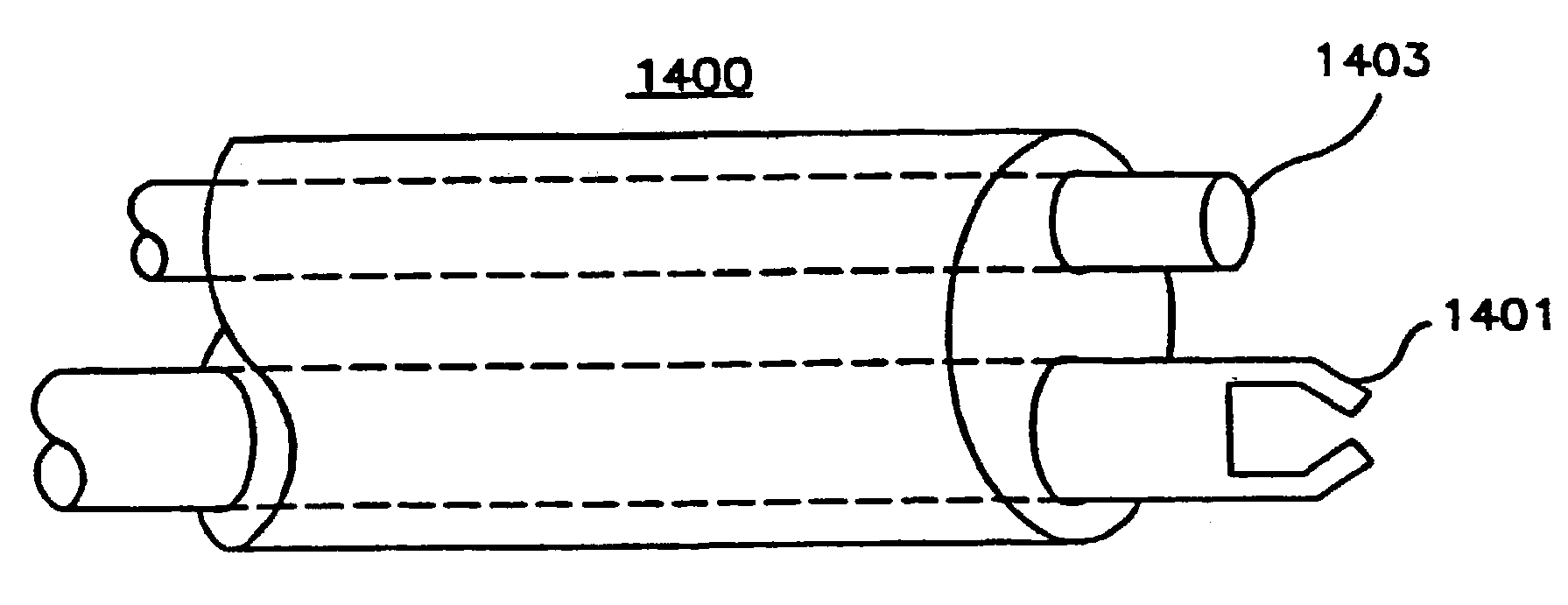

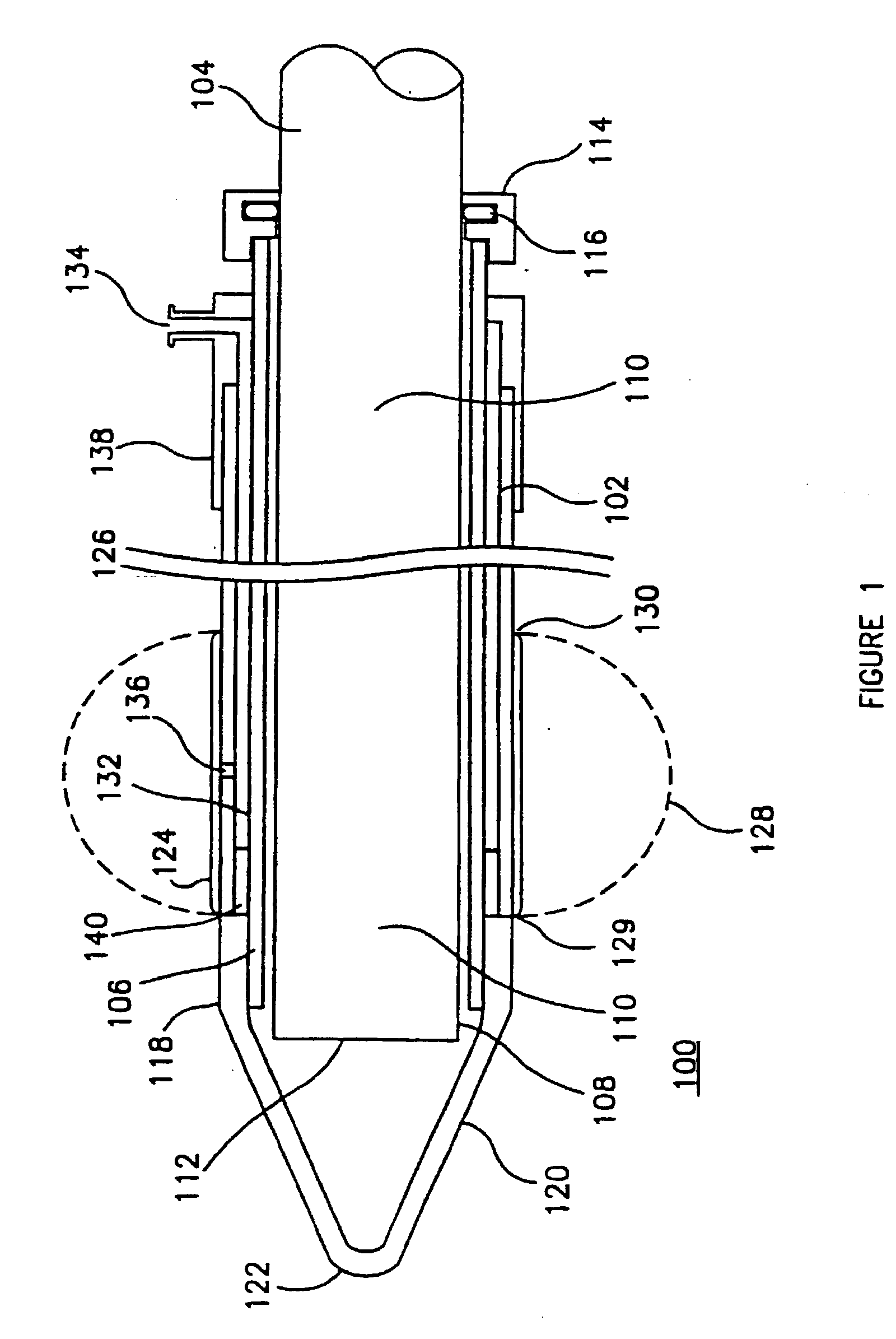

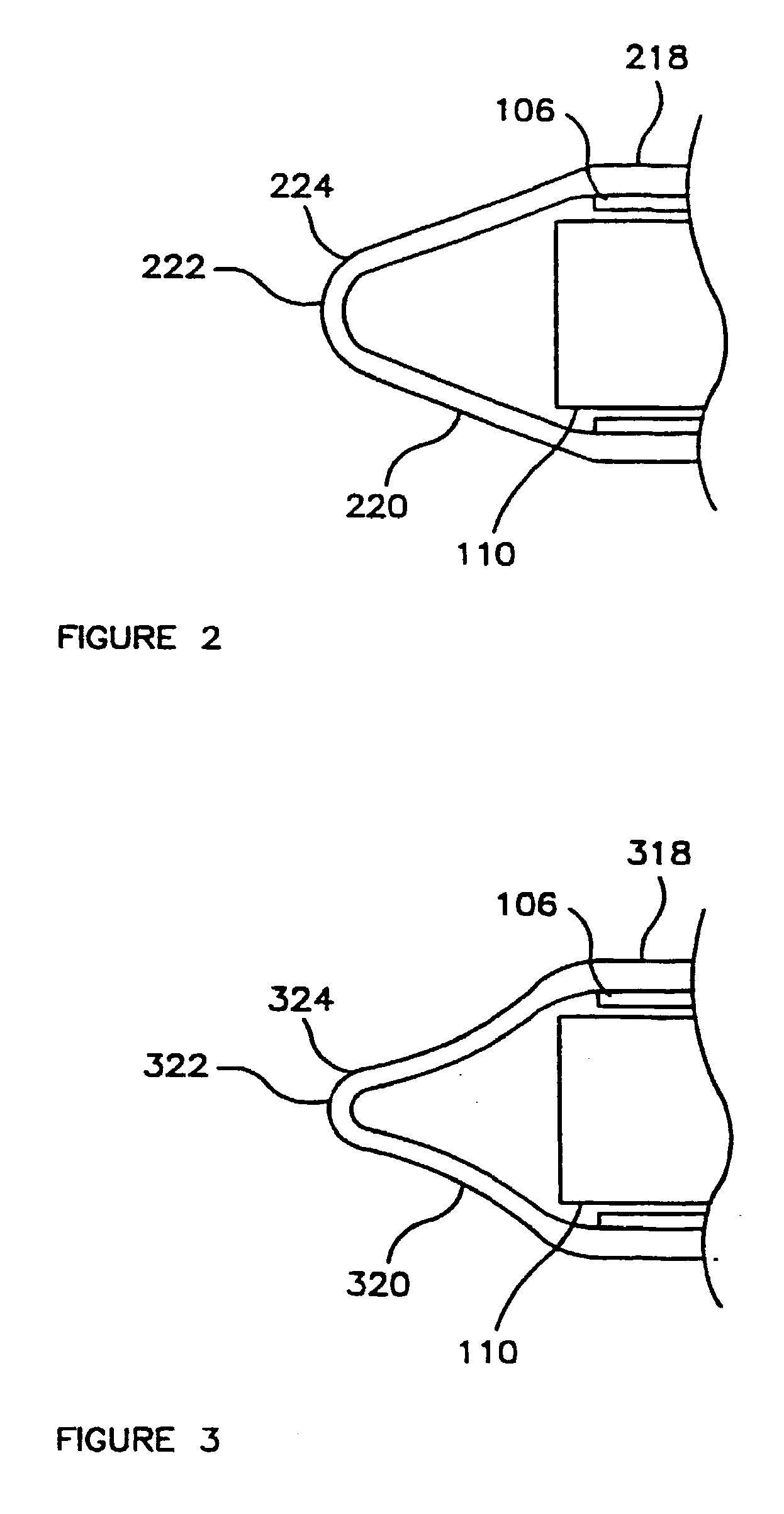

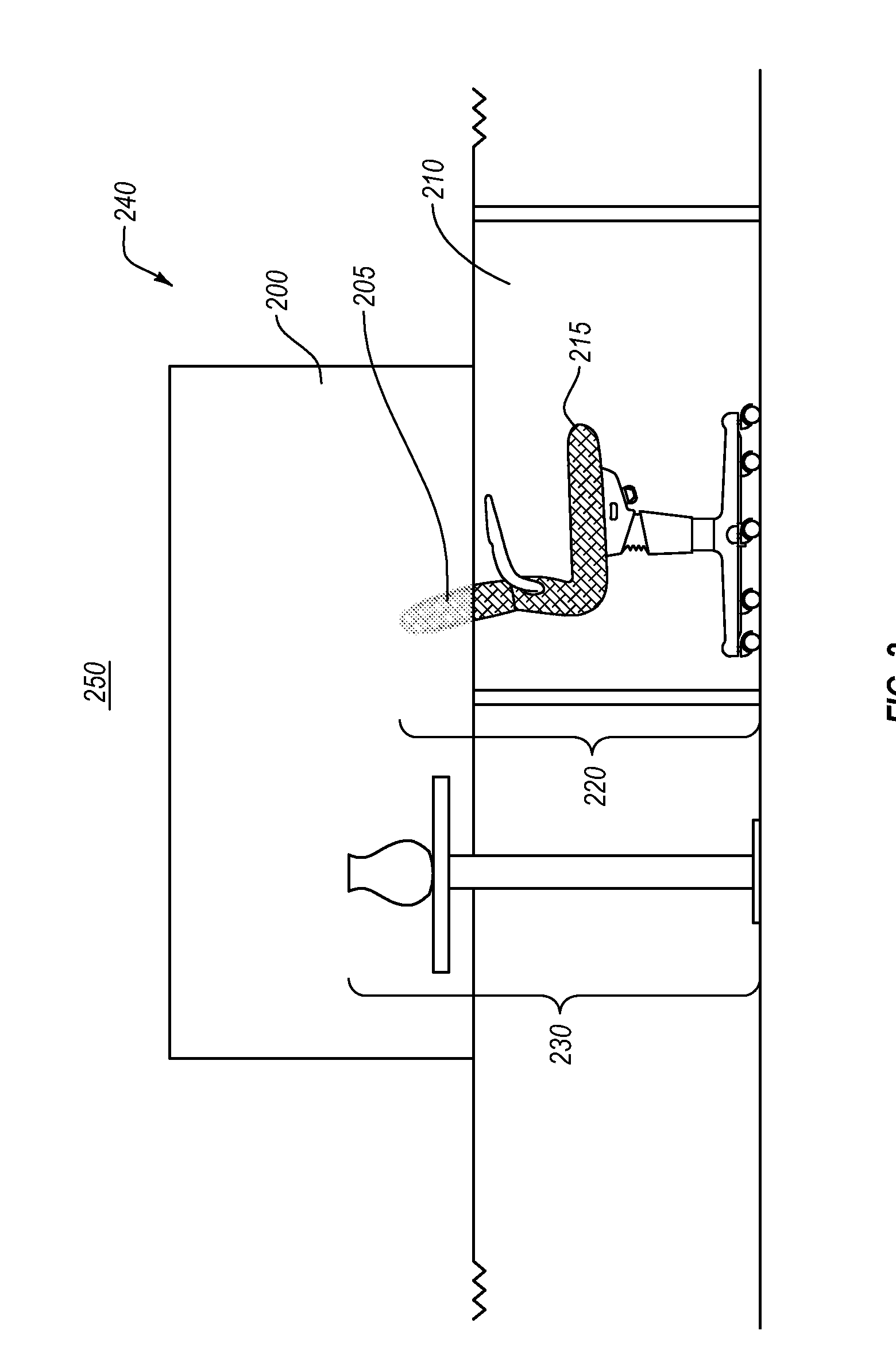

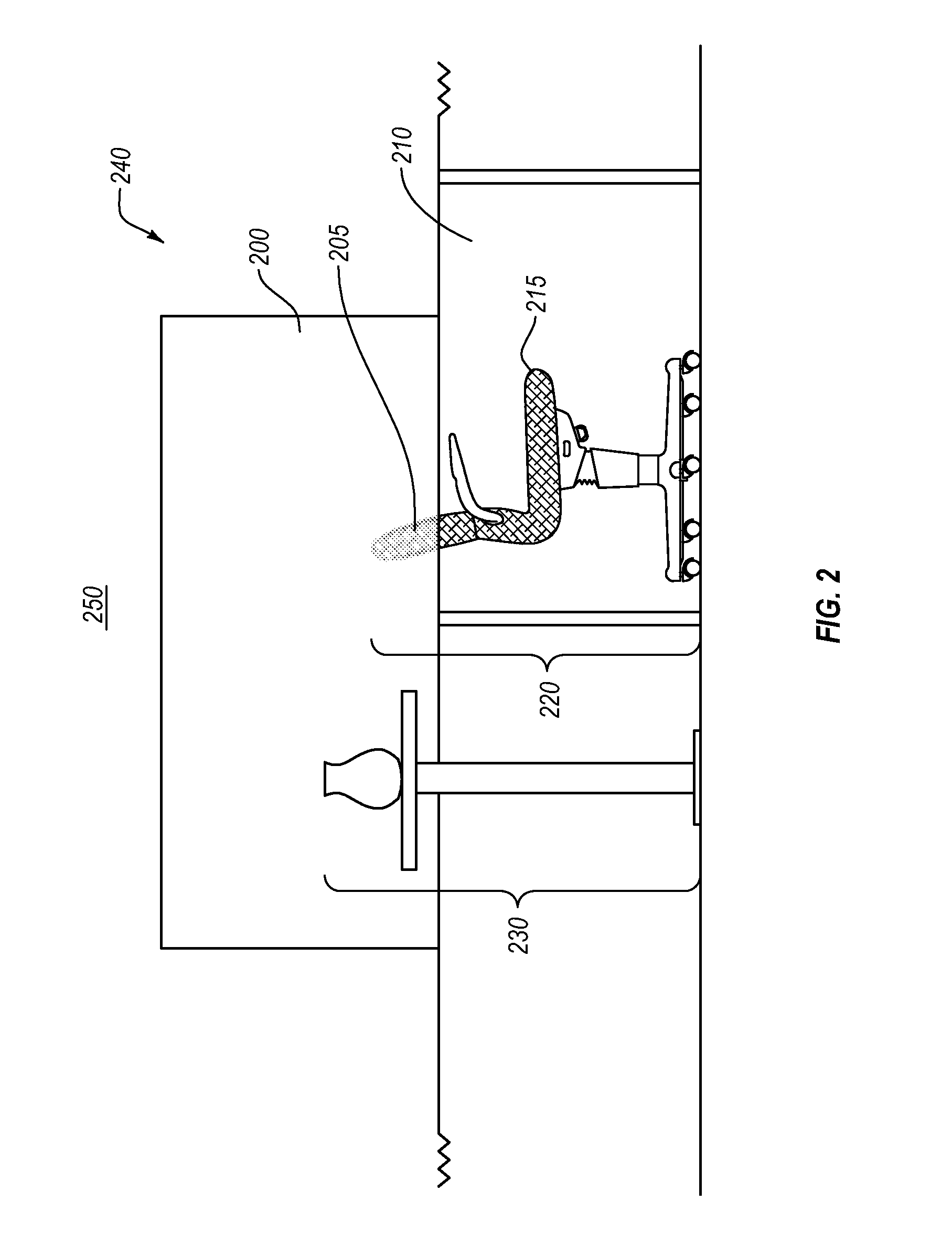

Tissue Dissection Method

InactiveUS20090024156A1Reduce distortion problemsIncision instrumentsSurgical needlesCoronary arteriesConnective tissue

A cannula includes a tubular body and an endoscope for viewing through a transparent, blunt, tissue-separating tip substantially covering the distal end of the body. Endoscopic viewing through the tip is enhanced by inner walls that taper to a cusp adjacent the blunt tip in order to reduce visual distortion. Alternatively, a cannula includes a dissection probe and a removable or deflectable tip for exposing the probe and endoscope to facilitate viewing and the dissection of connective tissue and lateral vessels along the dissected cavity. Methods of using such cannulas produce an elongated cavity along the course of a vessel for subsequent harvesting or other treatment of the isolated vessel. Lateral branch vessels of a main vessel to be harvested are doubly clipped or otherwise doubly occluded, and then severed to isolate the main vessel for use, for example, in revascularizing the coronary artery.

Owner:MAQUET CARDIOVASCULAR LLC

Stereo image stitching method based on content of images

InactiveCN105678687AEfficient splicingNo artificial ghostingGeometric image transformationParallaxImaging processing

The invention belongs to the technical field of stereo images, being able to realize effective stitching of stereo images, avoiding local deformation and reasonably reducing the vertical parallax. The invention relates to a stereo image stitching method based on content of images. The method comprises the steps: utilizing a consistent homography matrix after optimization to perform pre-deformation on the left and right images; utilizing an image tuning and warping method based on contents to optimize image stitching and avoid distortion of vision; and at last, utilizing a lookup algorithm based on kerf and a multi-tape mixed algorithm to acquire the final image stitching result. The stereo image stitching method based on content of images is mainly used for image processing.

Owner:TIANJIN UNIV

Video coding-decoding processing method

ActiveCN1710959AHigh precisionGood error concealmentPulse modulation television signal transmissionDigital video signal modificationComputer hardwareTransmission channel

The method includes steps: carrying out subprocess of transforming subblocks for each block inside each macro group respectively; sorting process is carried out for all subblocks after transform process inside each macro group; sending party sends encoded transformation coefficients of header information of each macro group, header information of macro block and each class of sub block group; receiving party carries out decoding proves for corrected received code stream respectively in order to recover image information of corresponding sub block; base on image information of relevant sub blocks, the receiving party carries out image information process in insertion approach algorithm for each sub block of containing error code. The invention is capable of carrying out process of anti error code more precisely for stream of error code caused by quality of transmission channel. Features are: lowering visual distortion of video image and raising effect of video communication.

Owner:TENCENT TECH (SHENZHEN) CO LTD

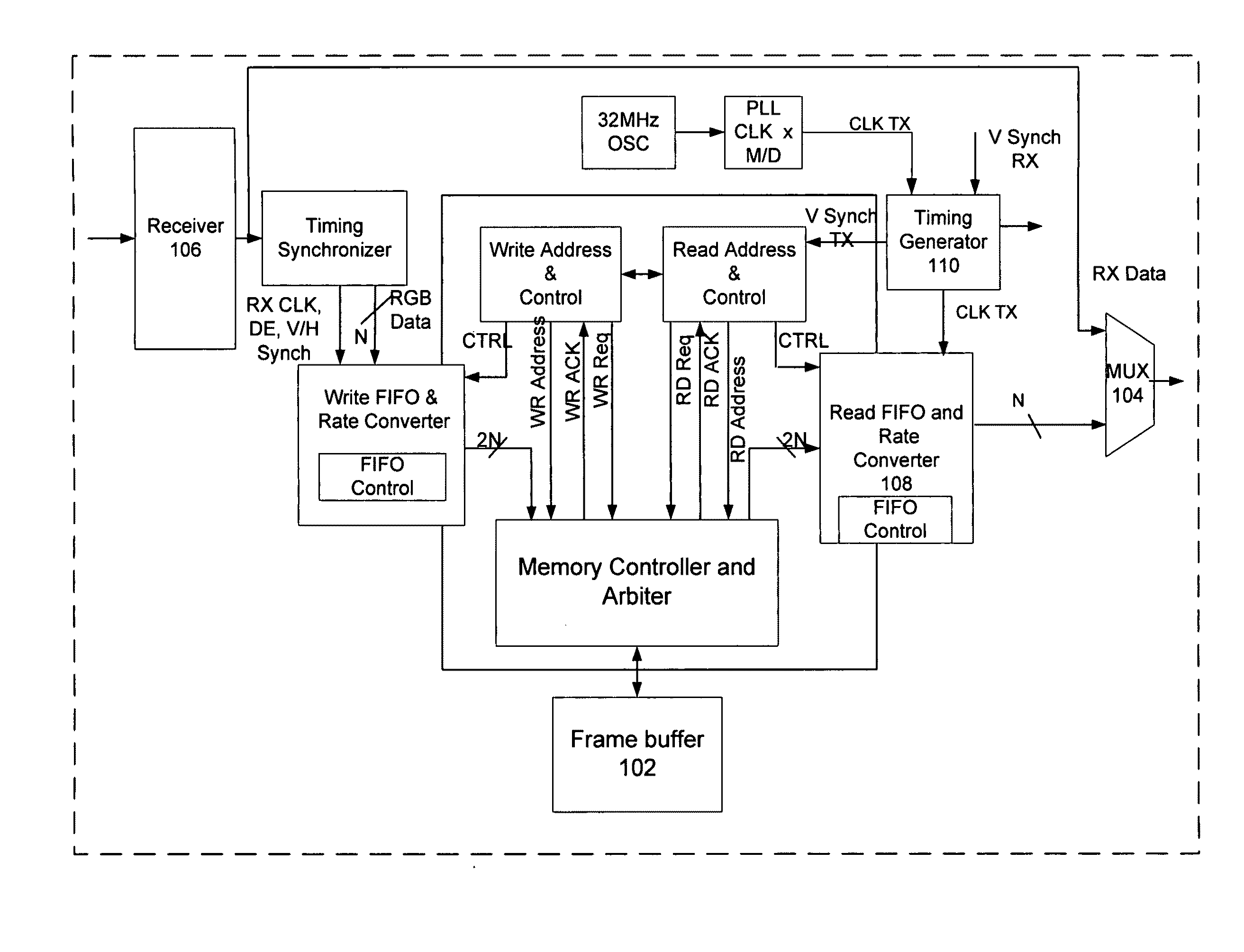

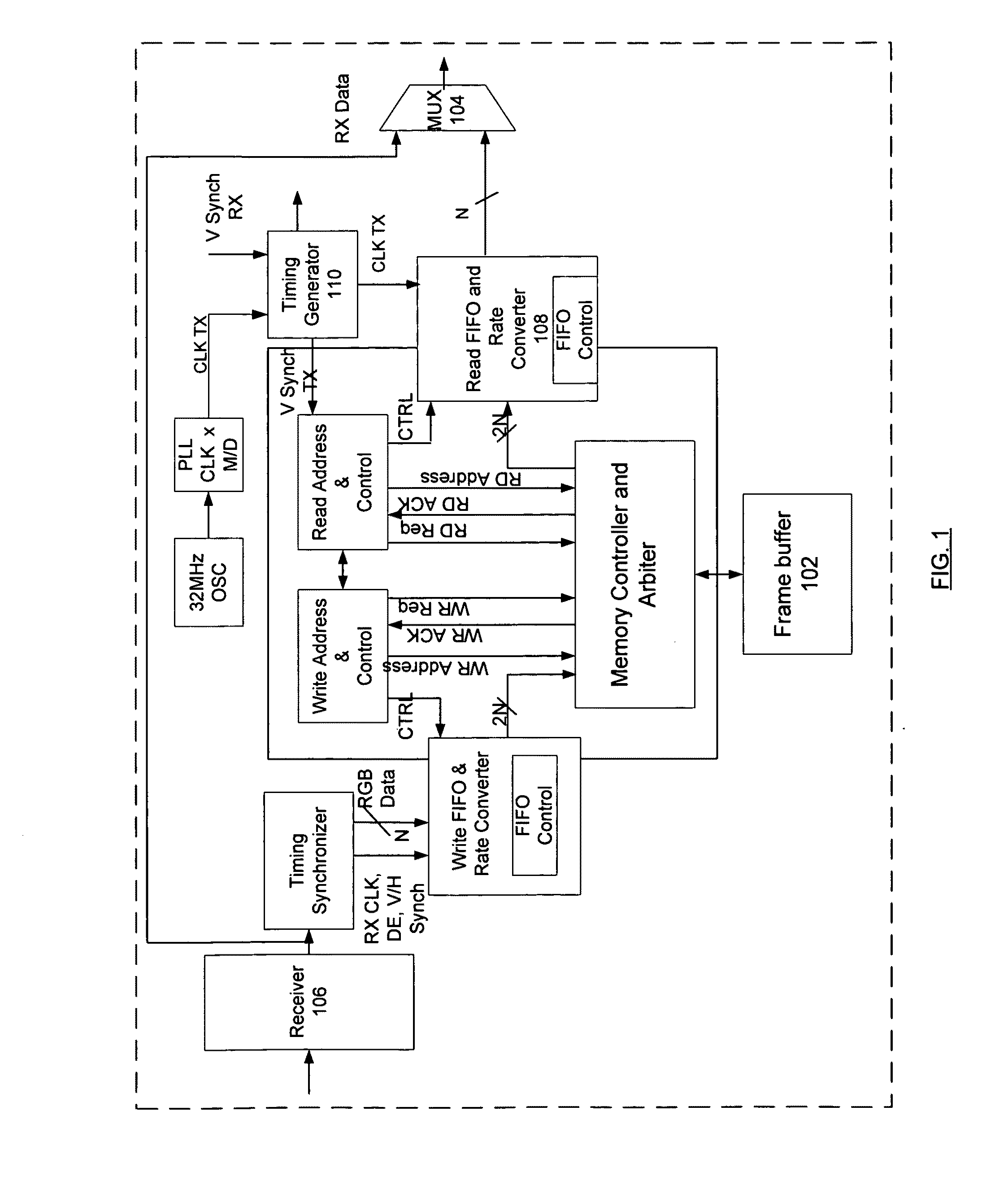

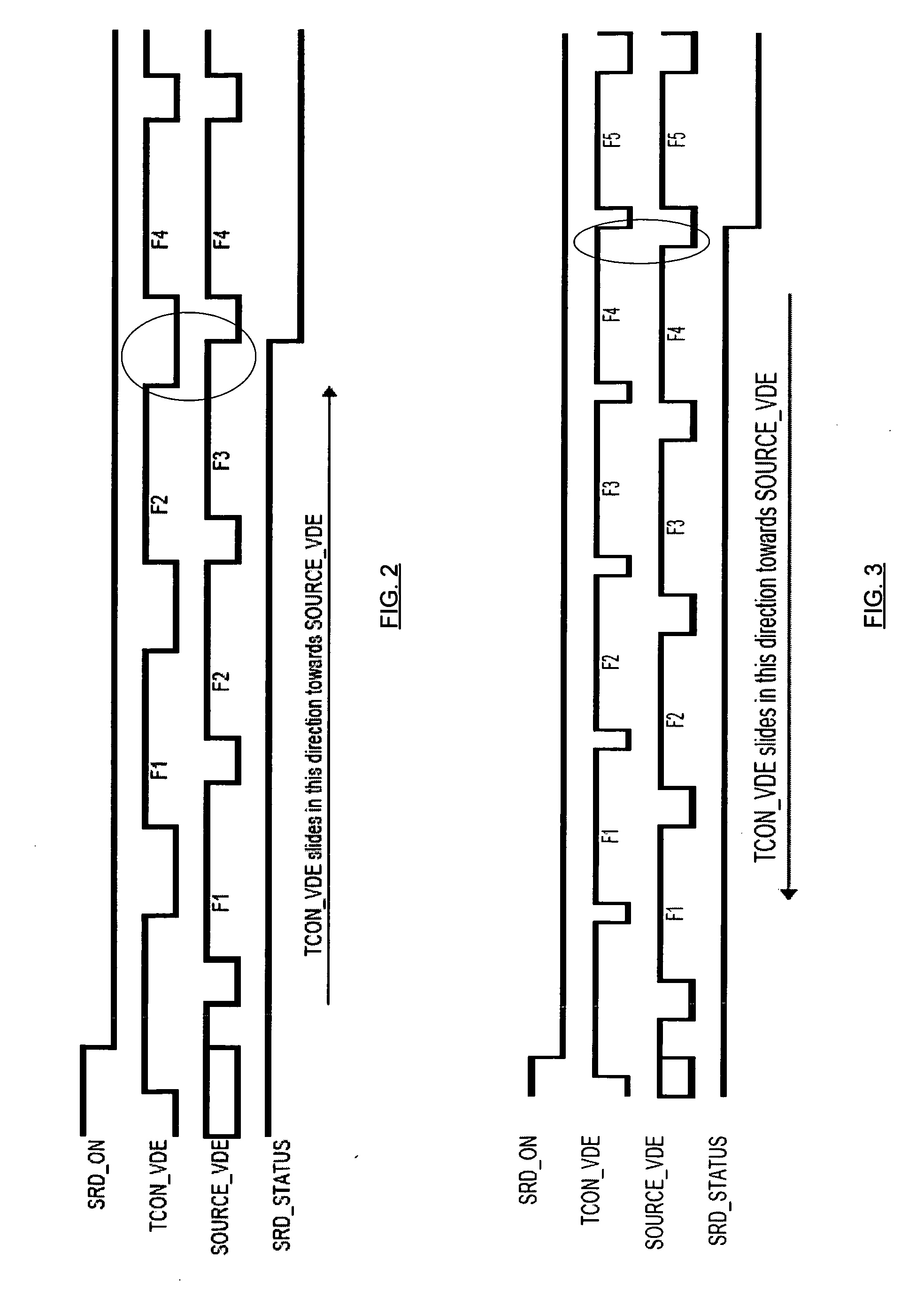

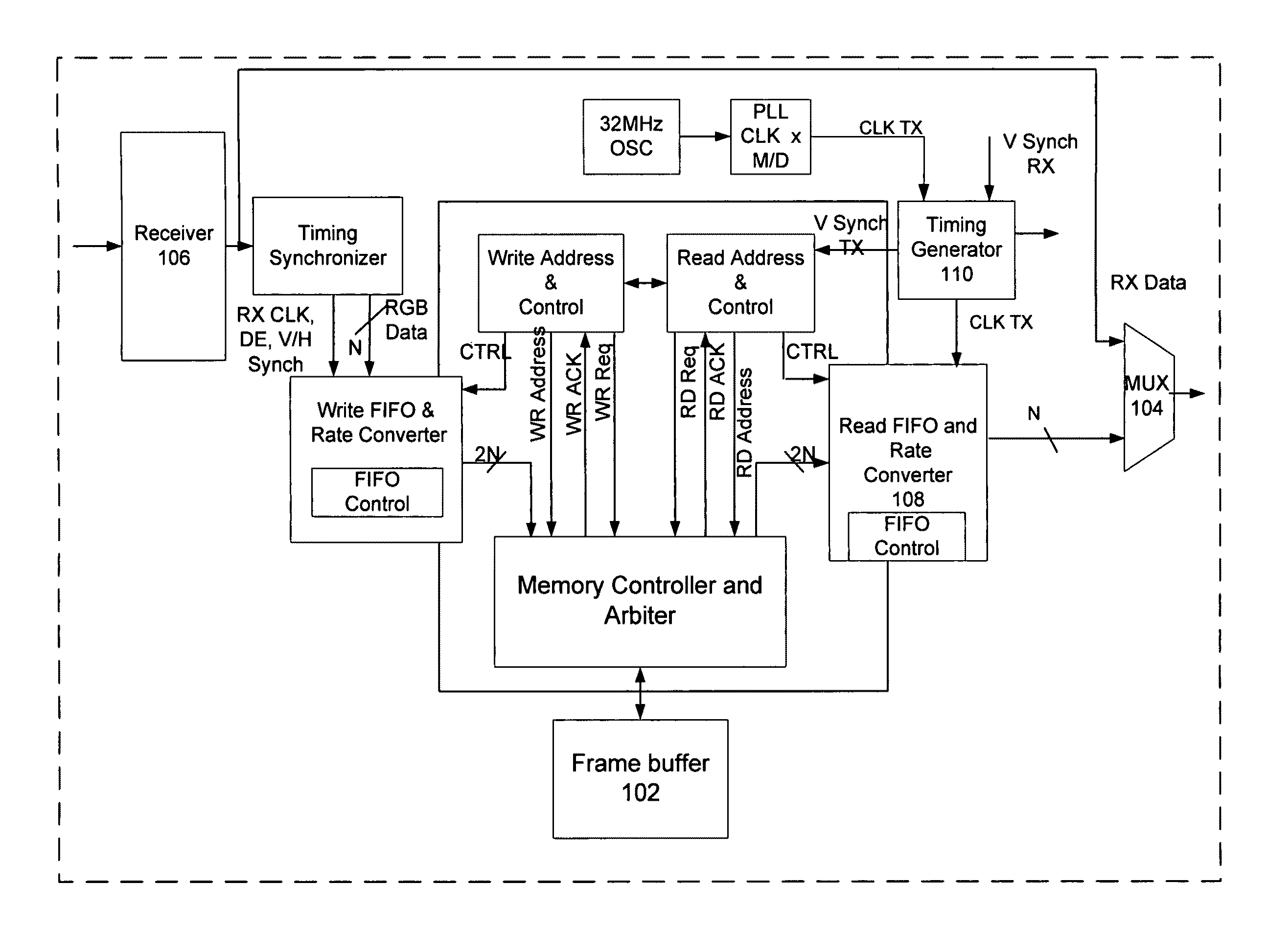

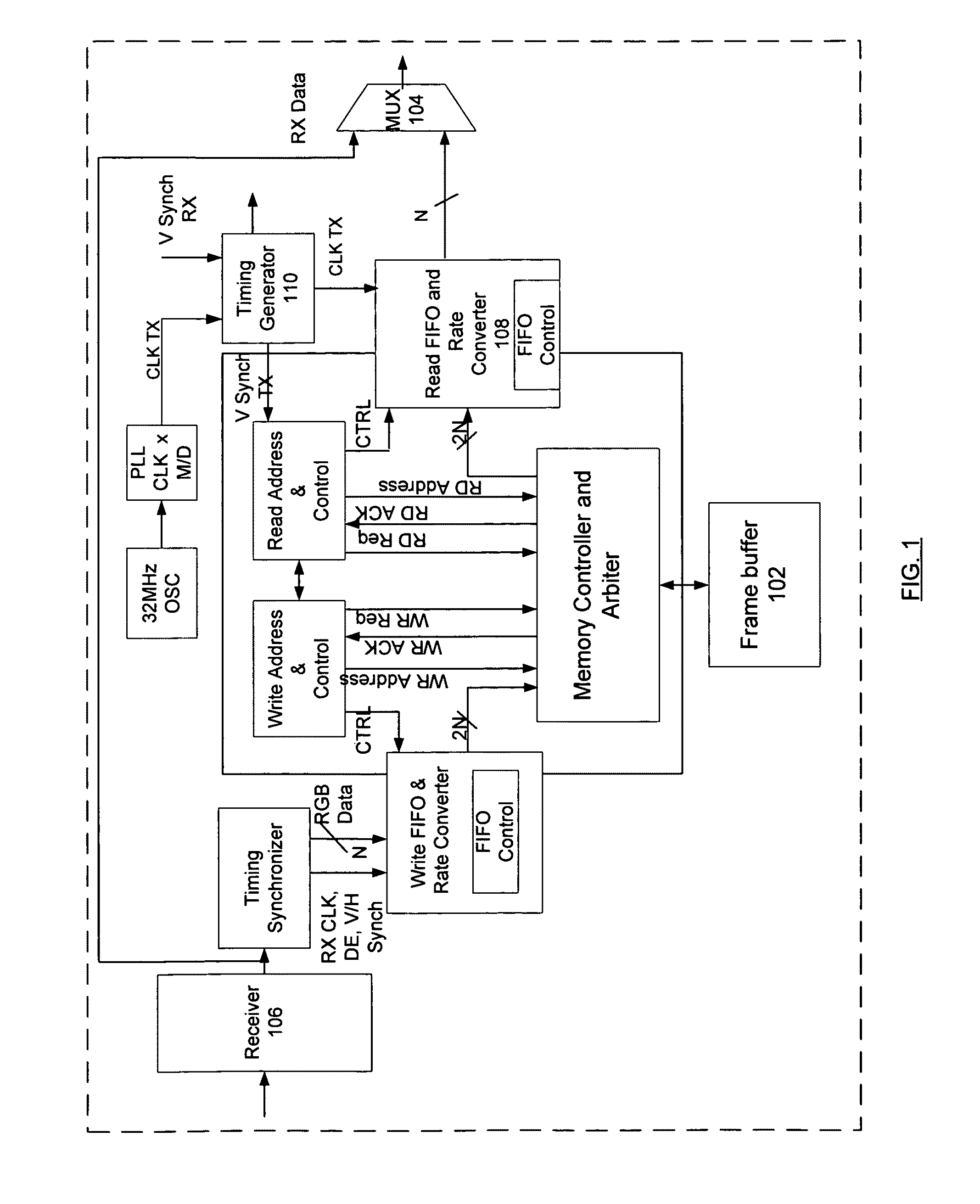

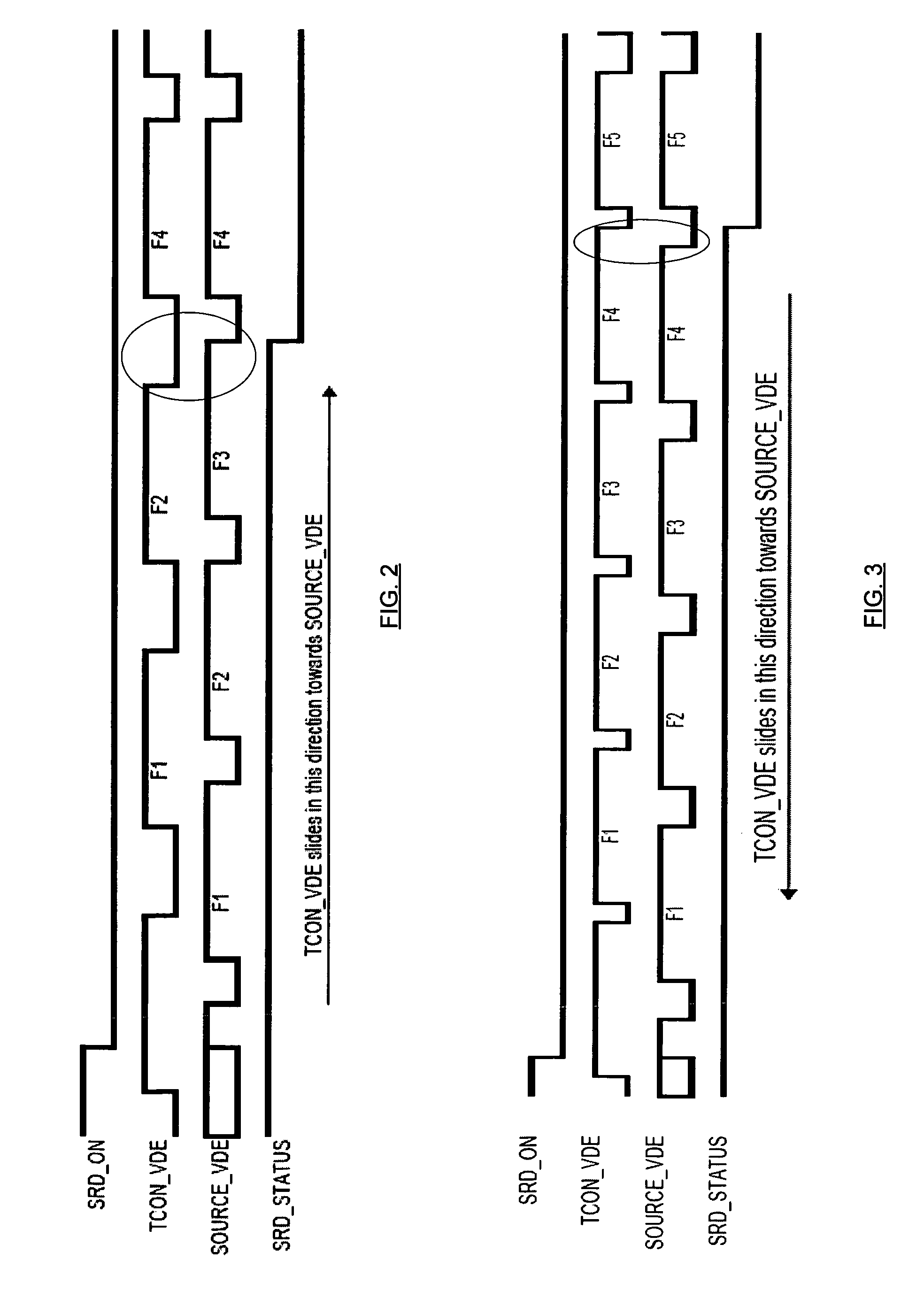

Techniques for aligning frame data

InactiveUS20110157198A1Cathode-ray tube indicatorsDigital output to display deviceComputer visionVisual distortion

Owner:INTEL CORP

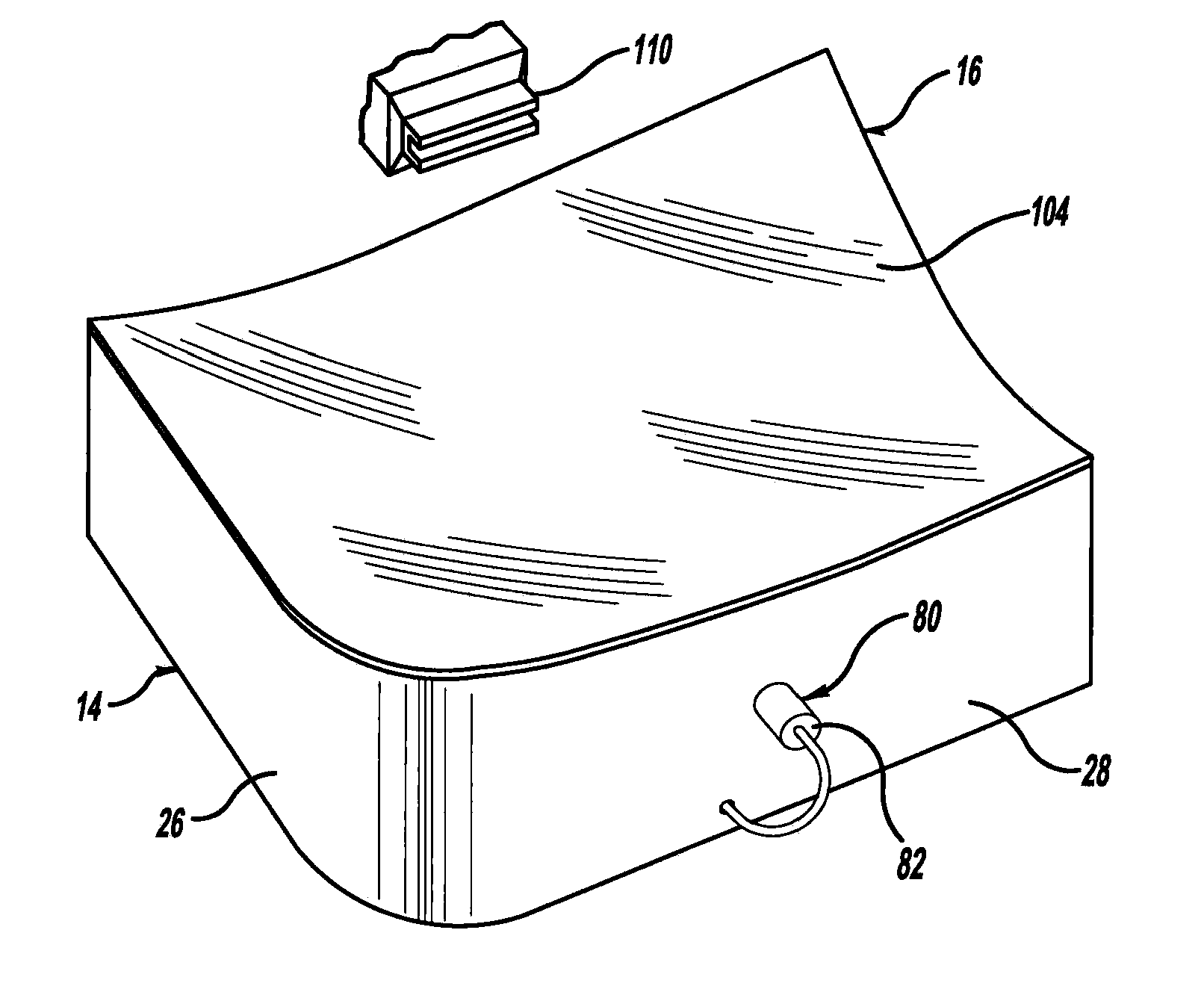

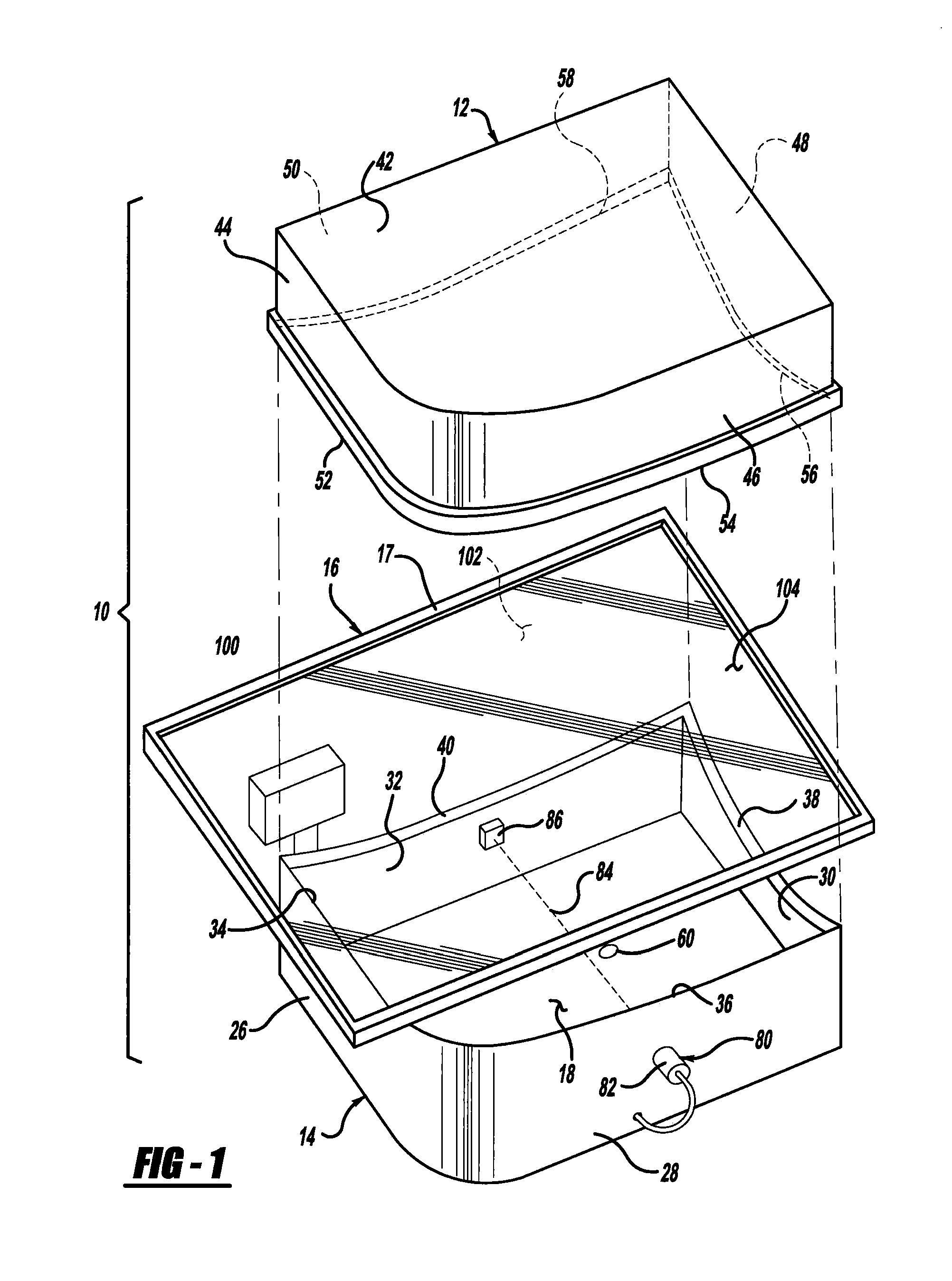

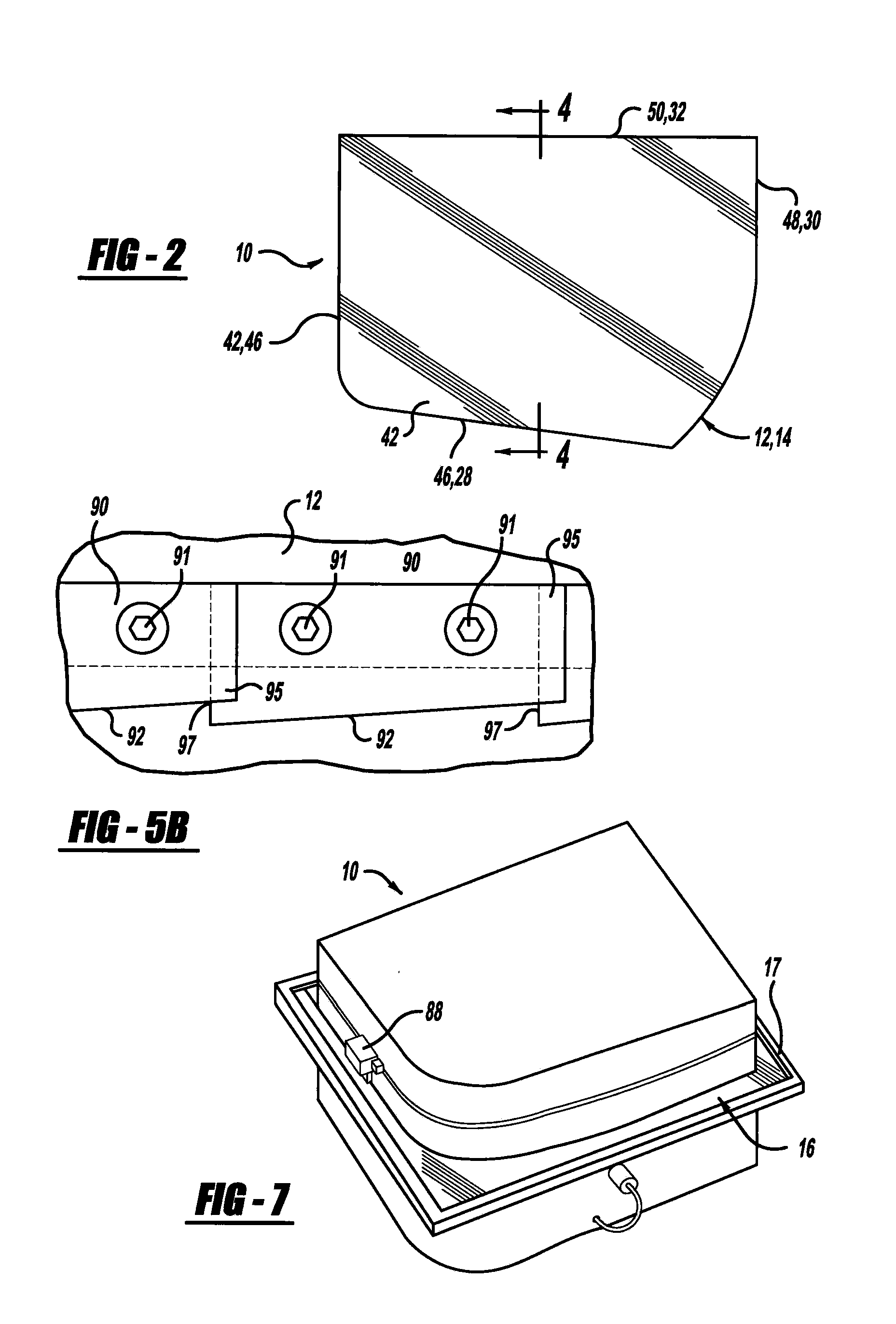

High-impact, transparent, distortion-free polymeric sheet and windshield

ActiveUS7425369B2Maintain good propertiesGood weather resistanceVehicle seatsConfectioneryDistortion freeUltraviolet

A base sheet of transparent polycarbonate material has a formed shape including a center portion and a peripheral portion. The center portion is formed by a non-contact forming operation occurring at a temperature above the glass transition temperature and below the melt temperature of the transparent polycarbonate material, thereby resulting in the center portion of the base sheet being free of visual distortion. A top coat layer is disposed over the base sheet. The top coat layer has a greater resistance to abrasion than the polycarbonate material and provides UV protection to the base sheet. A primer coating is disposed between the base sheet and the top coat layer to facilitate bonding therebetween. The peripheral portion can have a shape created by a contact forming operation occurring at a temperature above the glass transition temperature and below the melt temperature of the polycarbonate material.

Owner:CLEAR ARMOR LLC +1

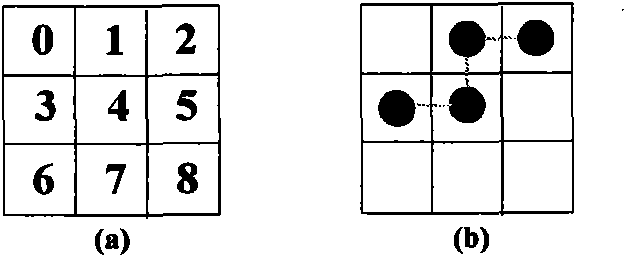

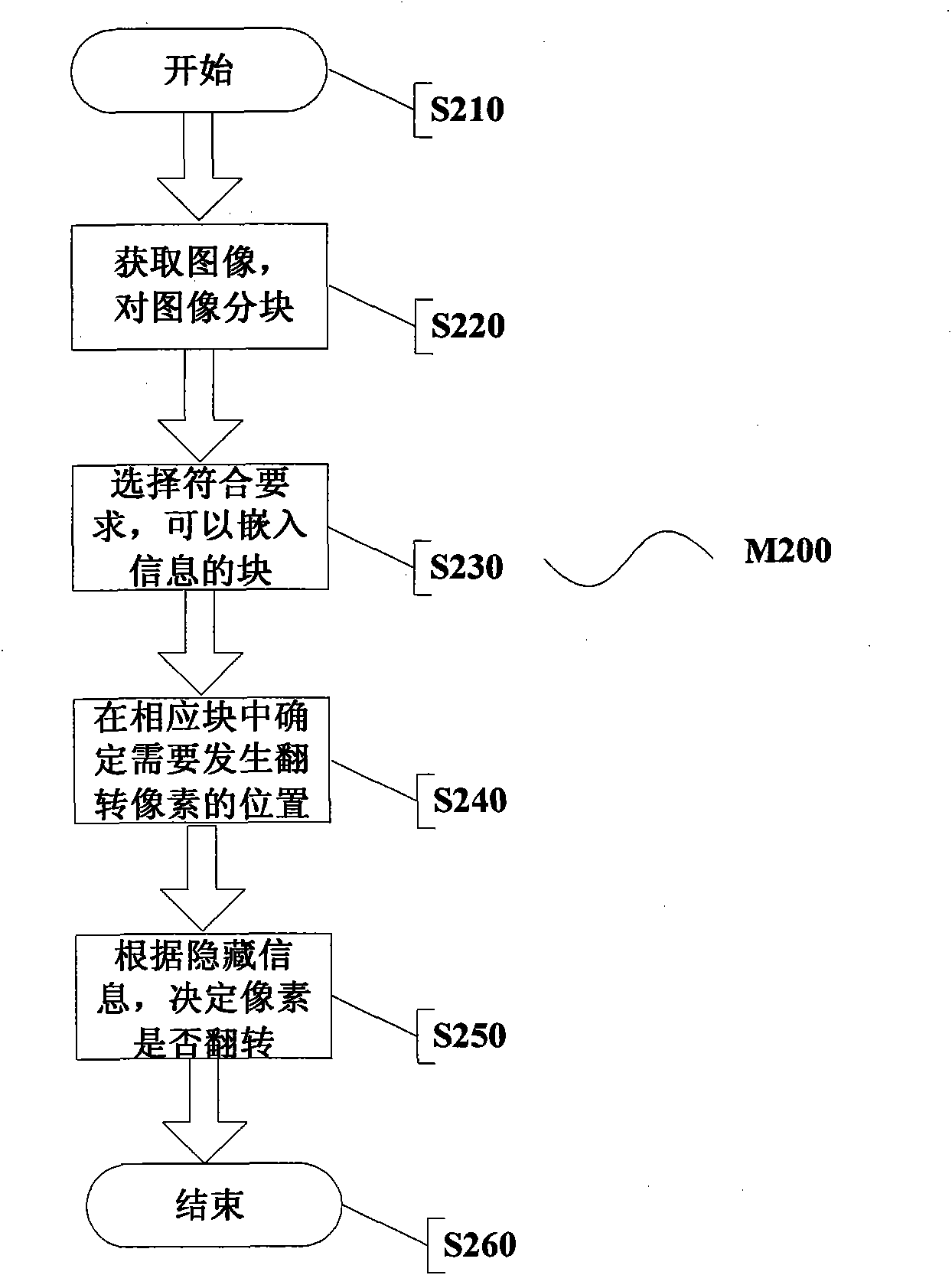

Binary image fragile watermark embedding and extraction method based on topology structure

InactiveCN101976428AHide fastQuick extractionImage data processing detailsPattern recognitionGraphics

The invention relates to a binary image fragile watermark embedding and extraction method based on a topology structure, comprising the following steps: blocking an original image, selecting hidden blocks capable of embedding information, turning white (or black) pixel points through a hidden method based on topology principle, and embedding hidden information required to be embedded to corresponding blocks. Through the invention, hidden information can be rapidly embedded and extracted, thus realizing required hidden information capacity and visual hidden effect. In the invention, blind extract can be realized, and more embedded hidden information capacity can be provided through the auxiliary of the original image under the condition of ensuring the same level of visual distortion effect. The invention also provides copyright protection at a certain security level, and further can provide strengthened security protection. By using the invention, copyright mark and integrity testing can be carried out on binary images in various types, such as calligraphy, woodblock prints, scanning images, handwritten signatures and the like, therefore, the invention can play roles in copyright protection, copyright control and certification at a certain level.

Owner:NANKAI UNIV

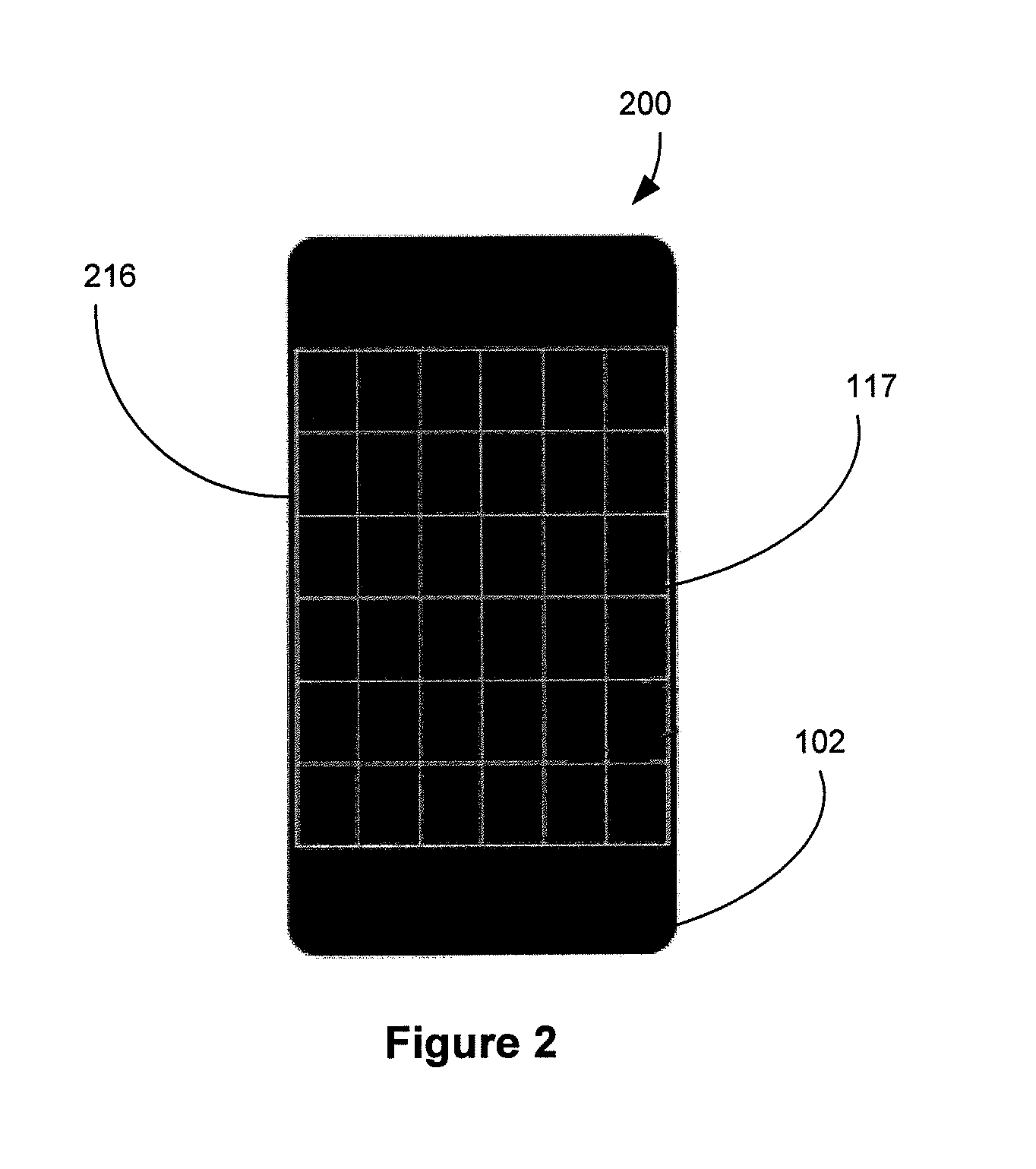

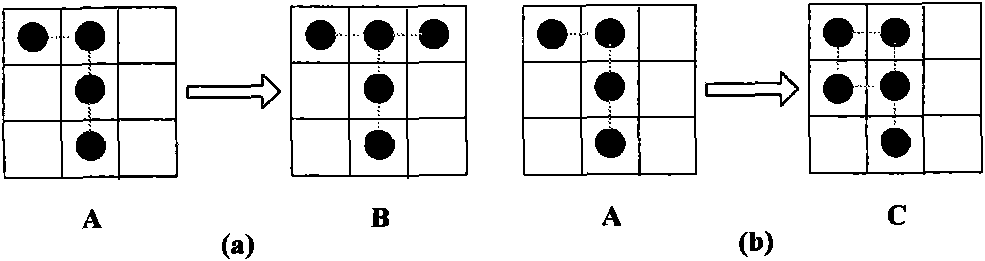

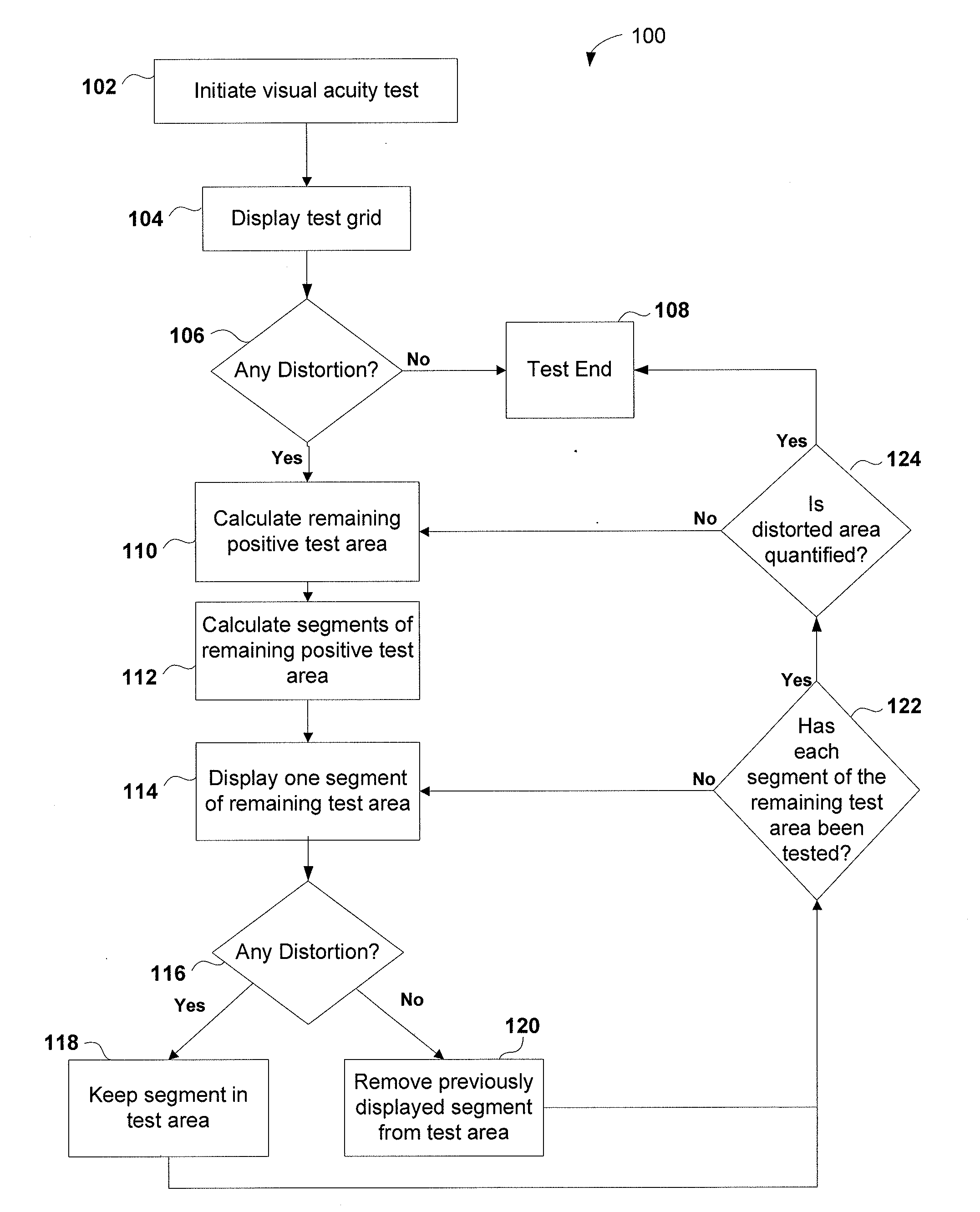

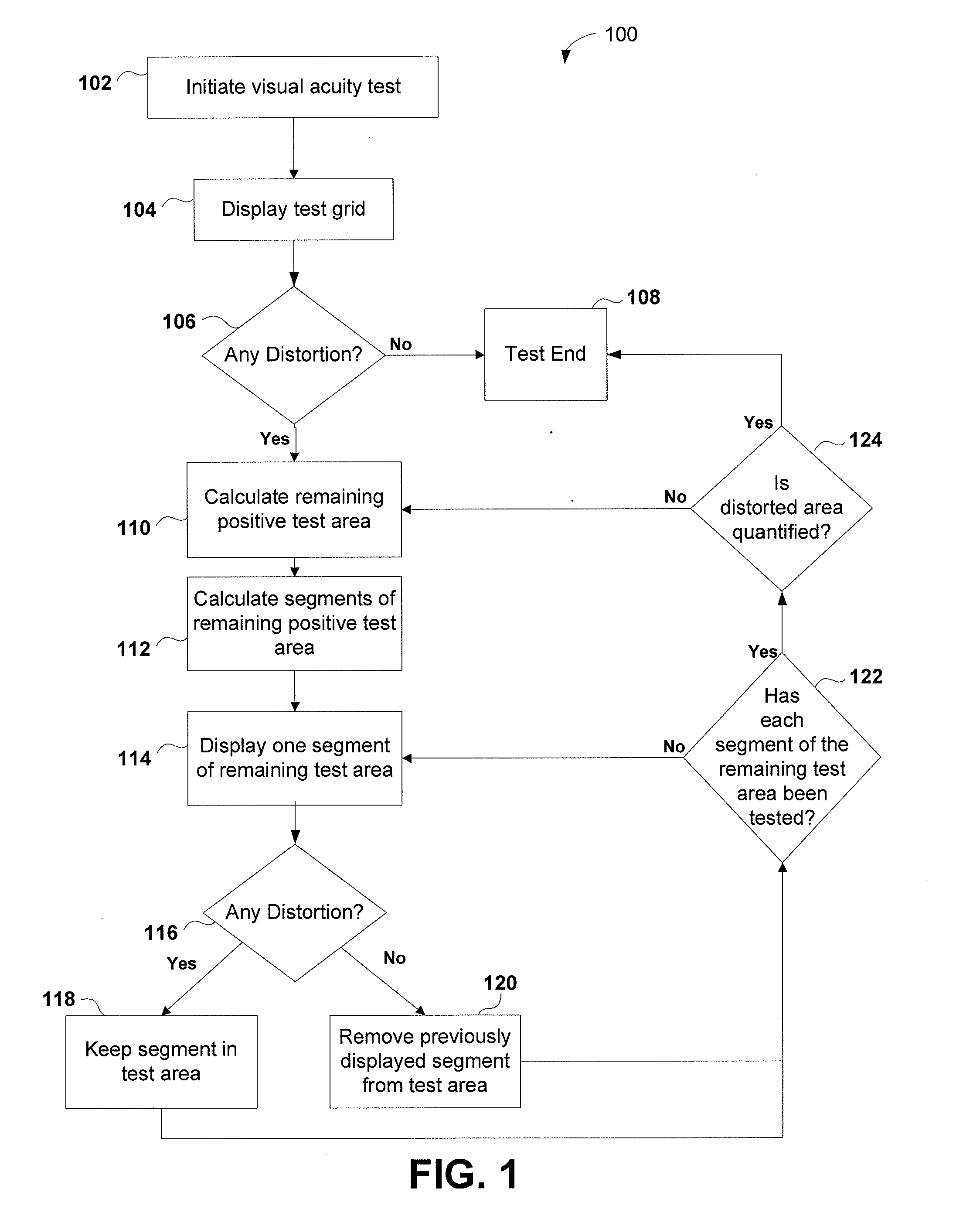

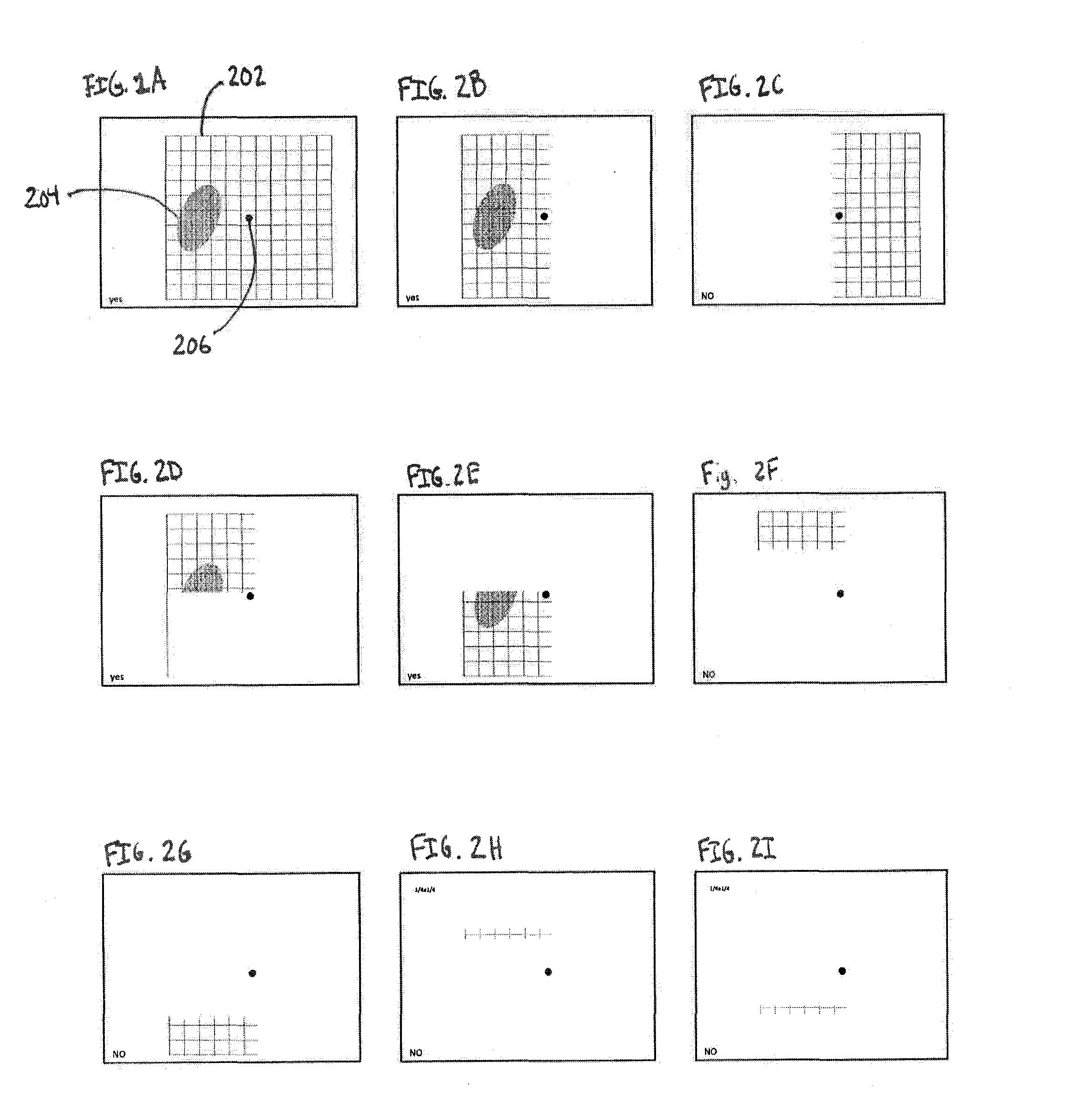

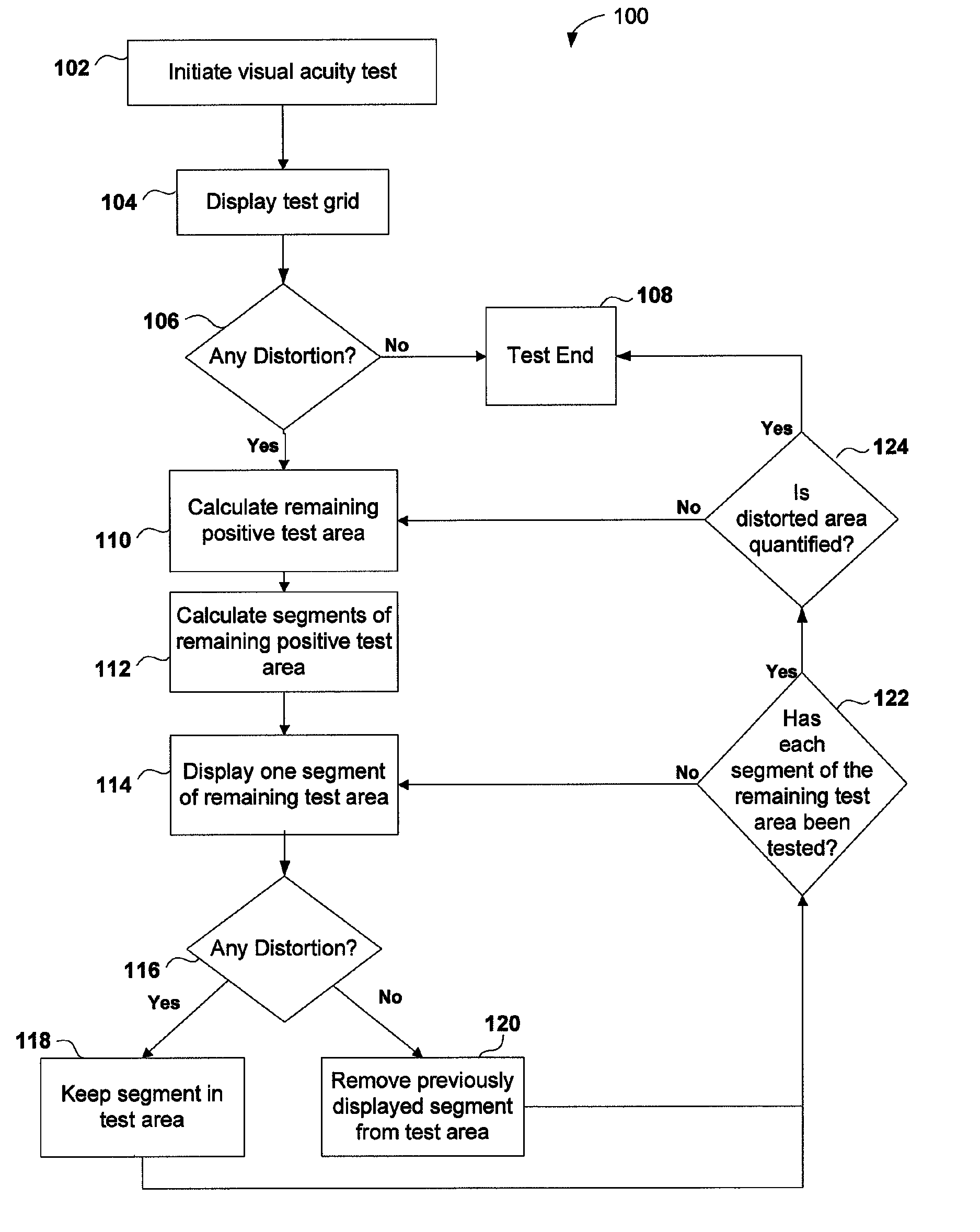

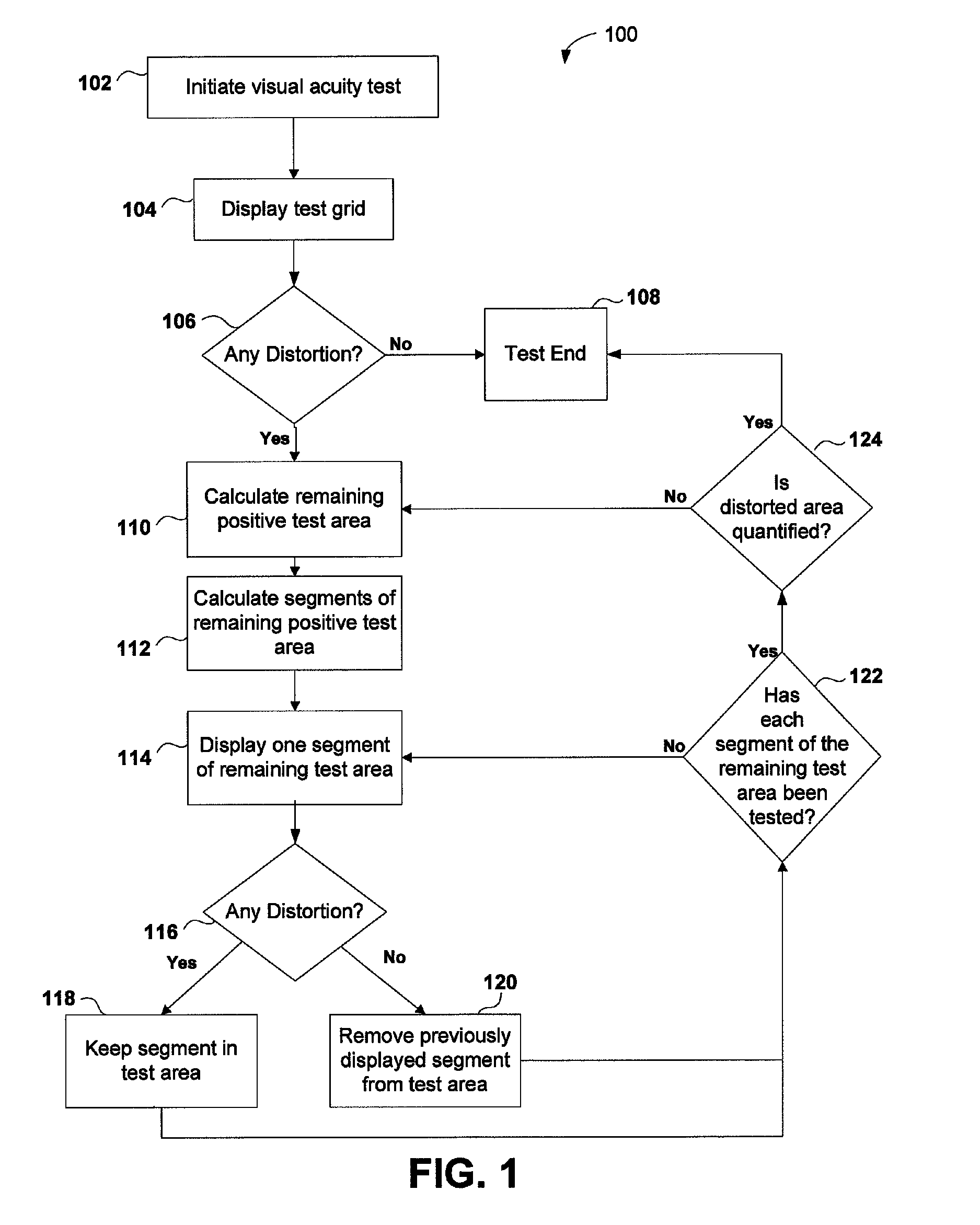

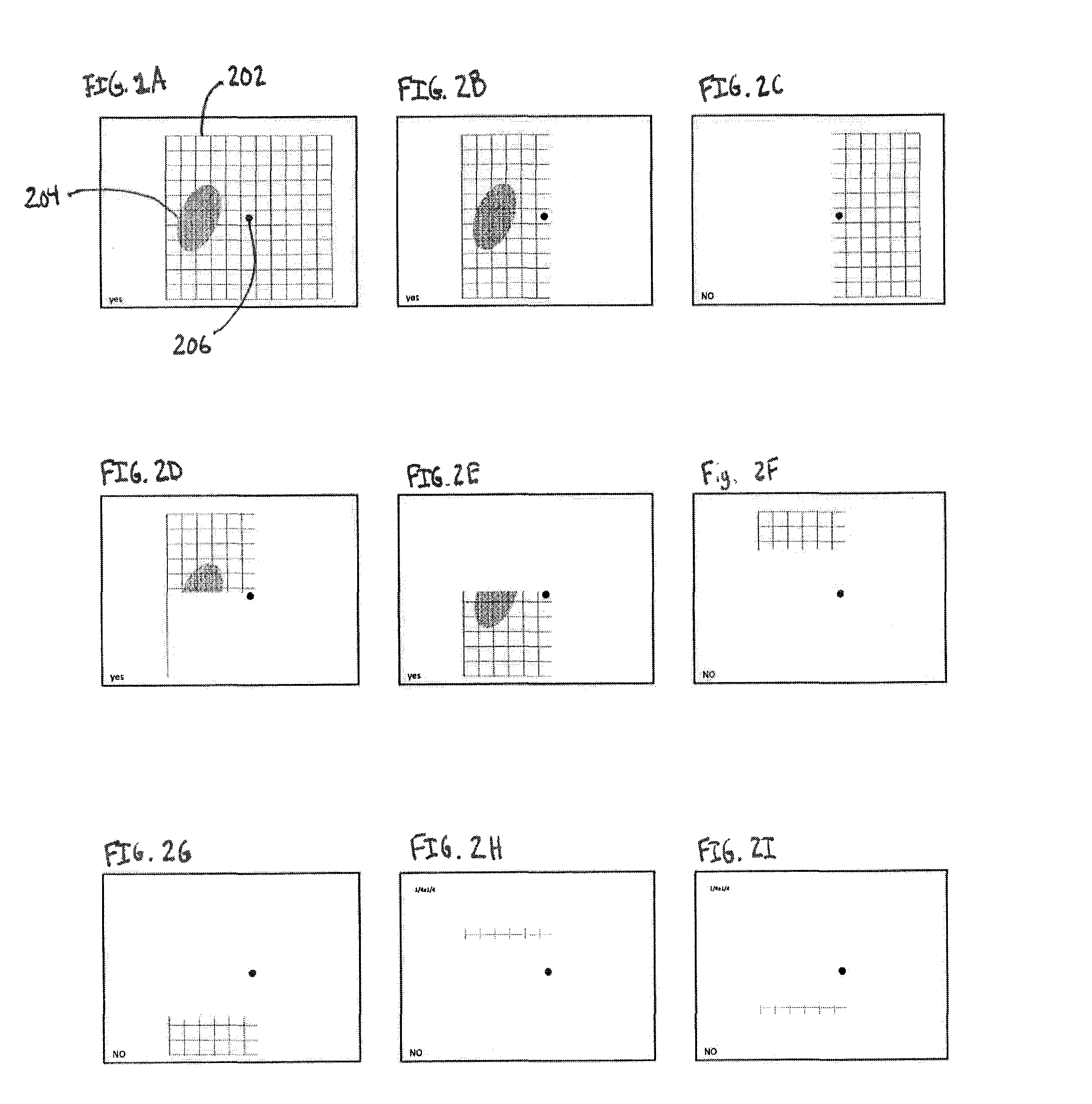

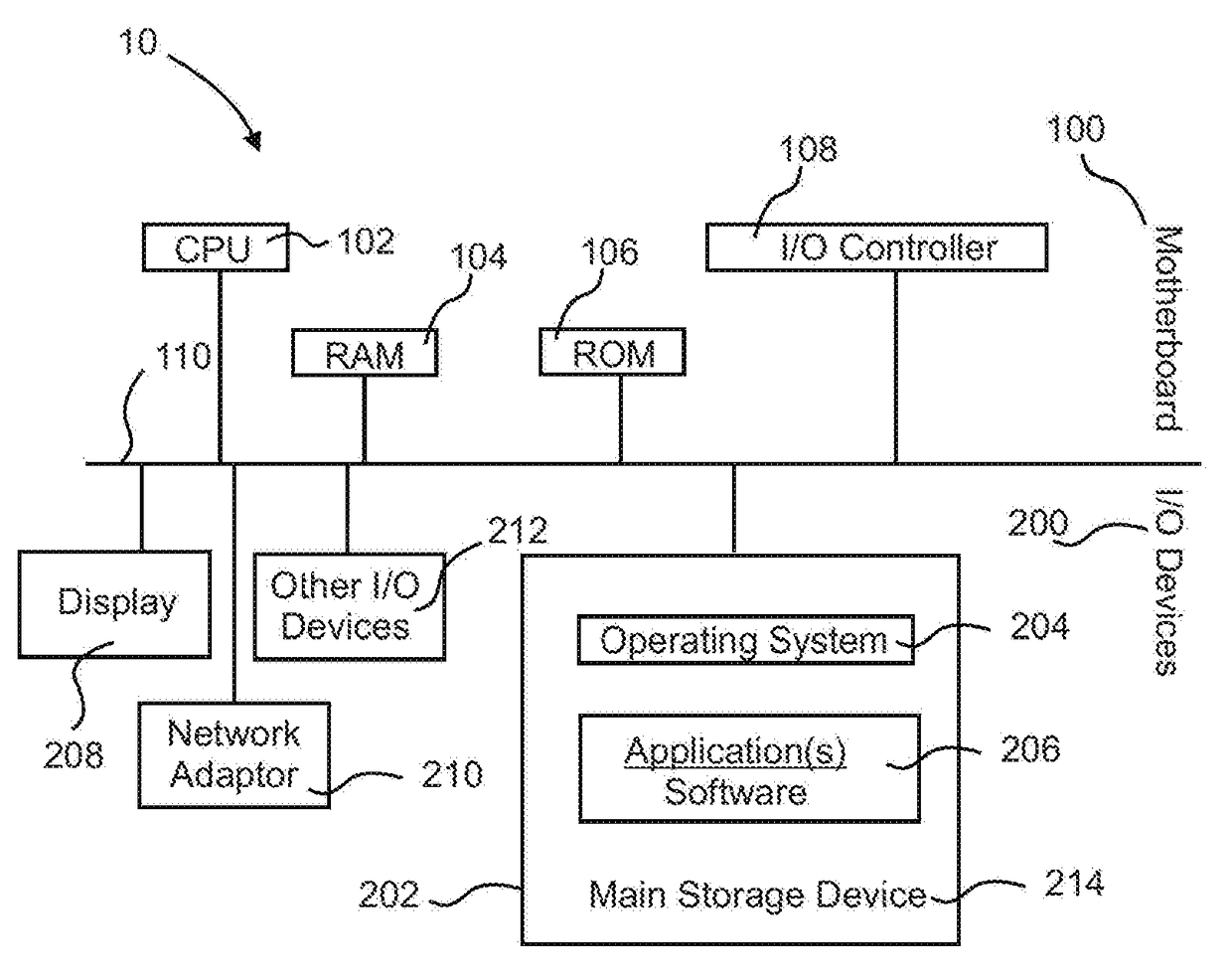

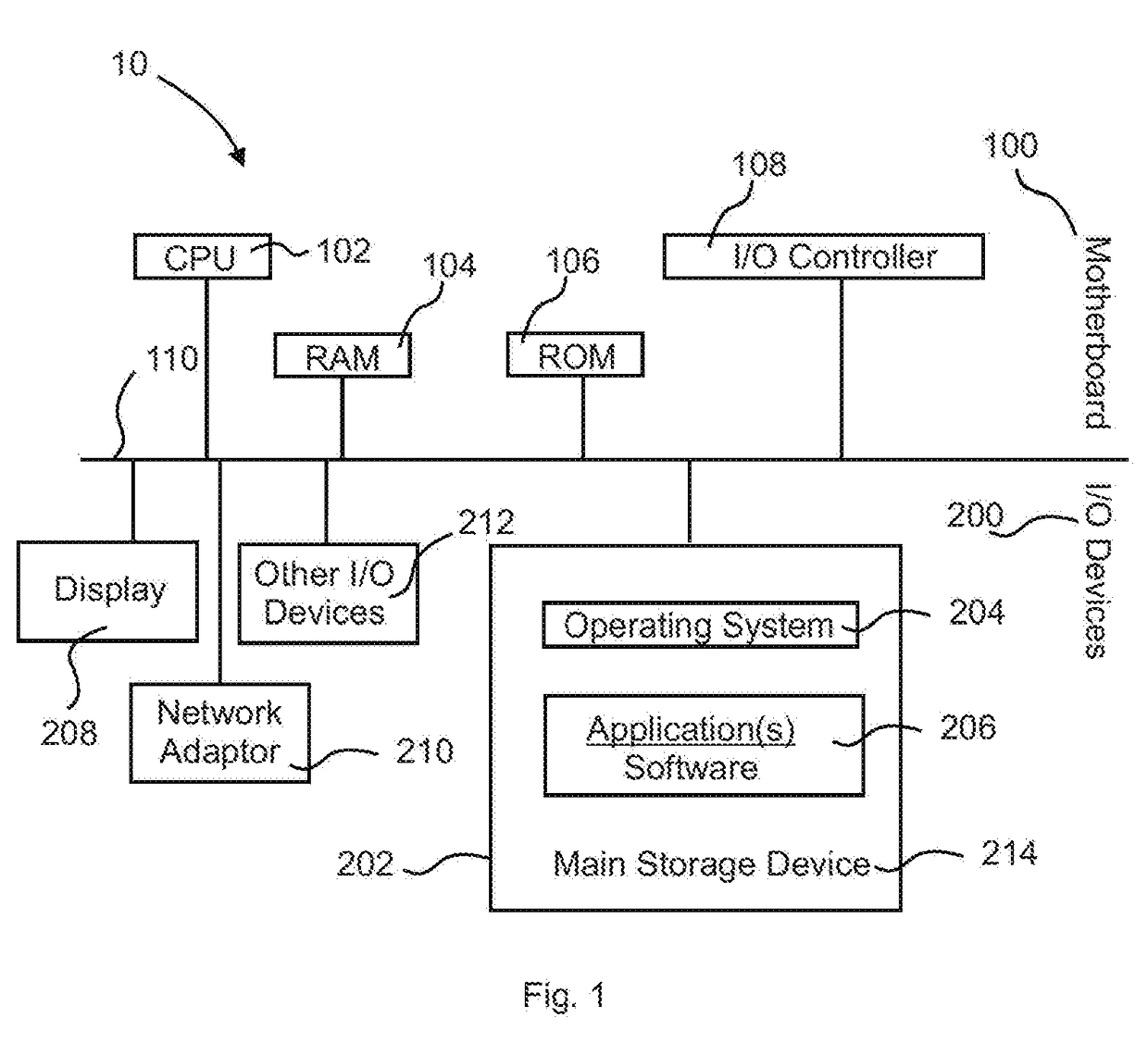

Metamorphopsia testing and related methods

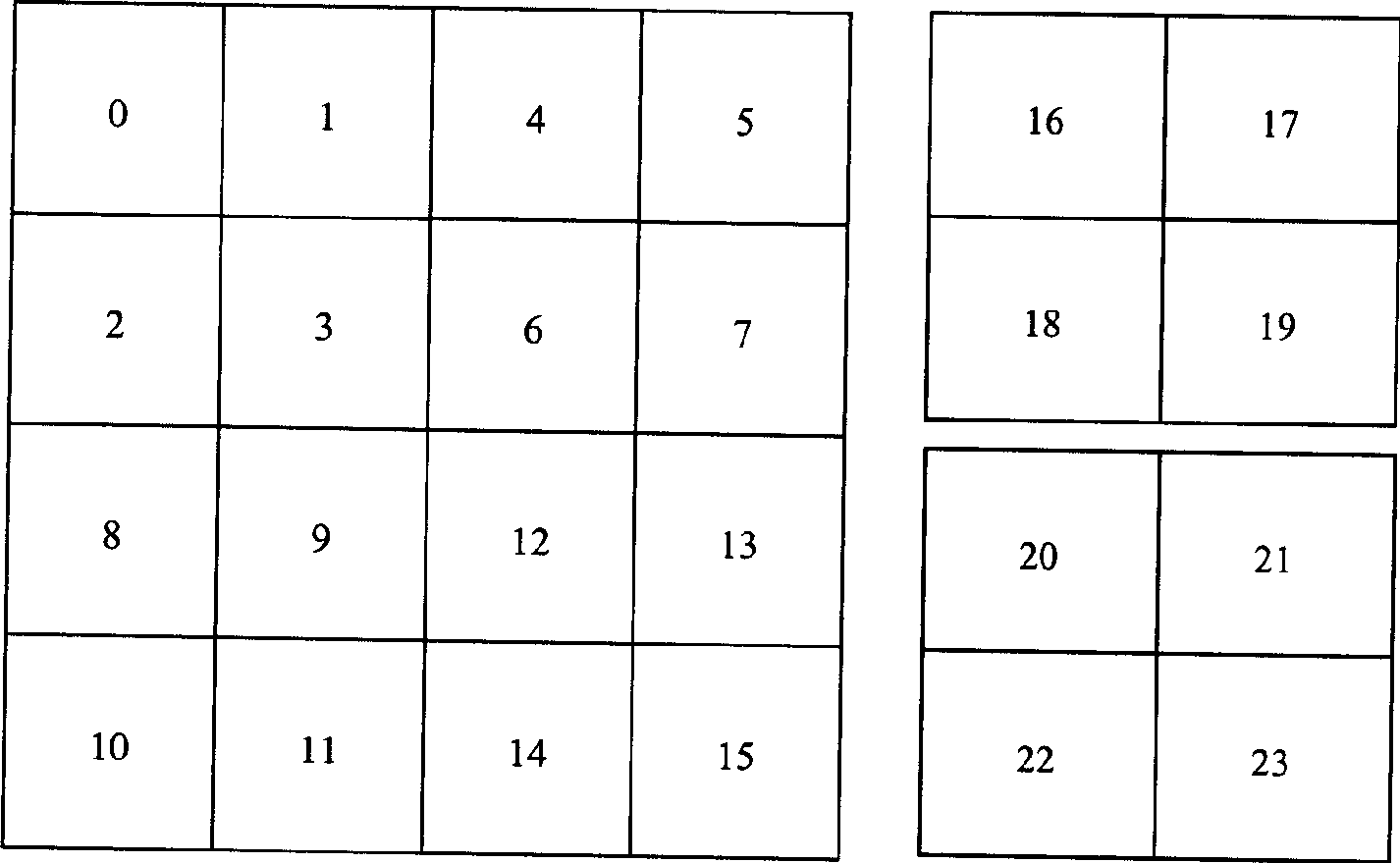

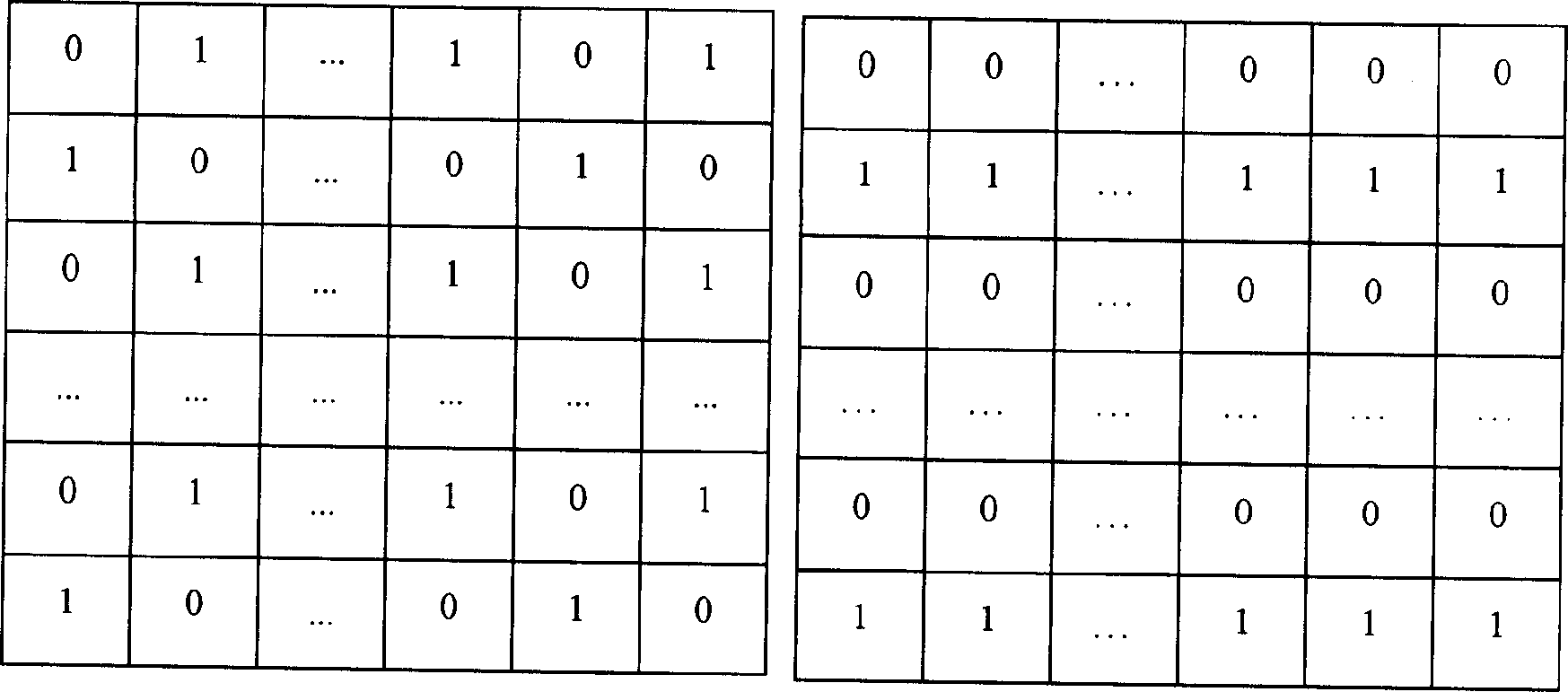

A visual distortion test is disclosed using a sequence of binary interactions with a mobile device, in which segments of the grid having no distortions are eliminated, and the segments with distortions are divided into smaller segments for further analysis. The test can quantify the visual distortion using a decreased number of steps, compared to sequential analysis of all the segments of the grid. The binary interaction or input to the mobile device is also easier for patients than graphic interactions with a conventional Amsler Grid. Early detection of changes in the visual distortion can enable the healthcare provider to individualize treatment, helping to prevent vision loss while minimizing visits to the office, discomfort, and expense.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

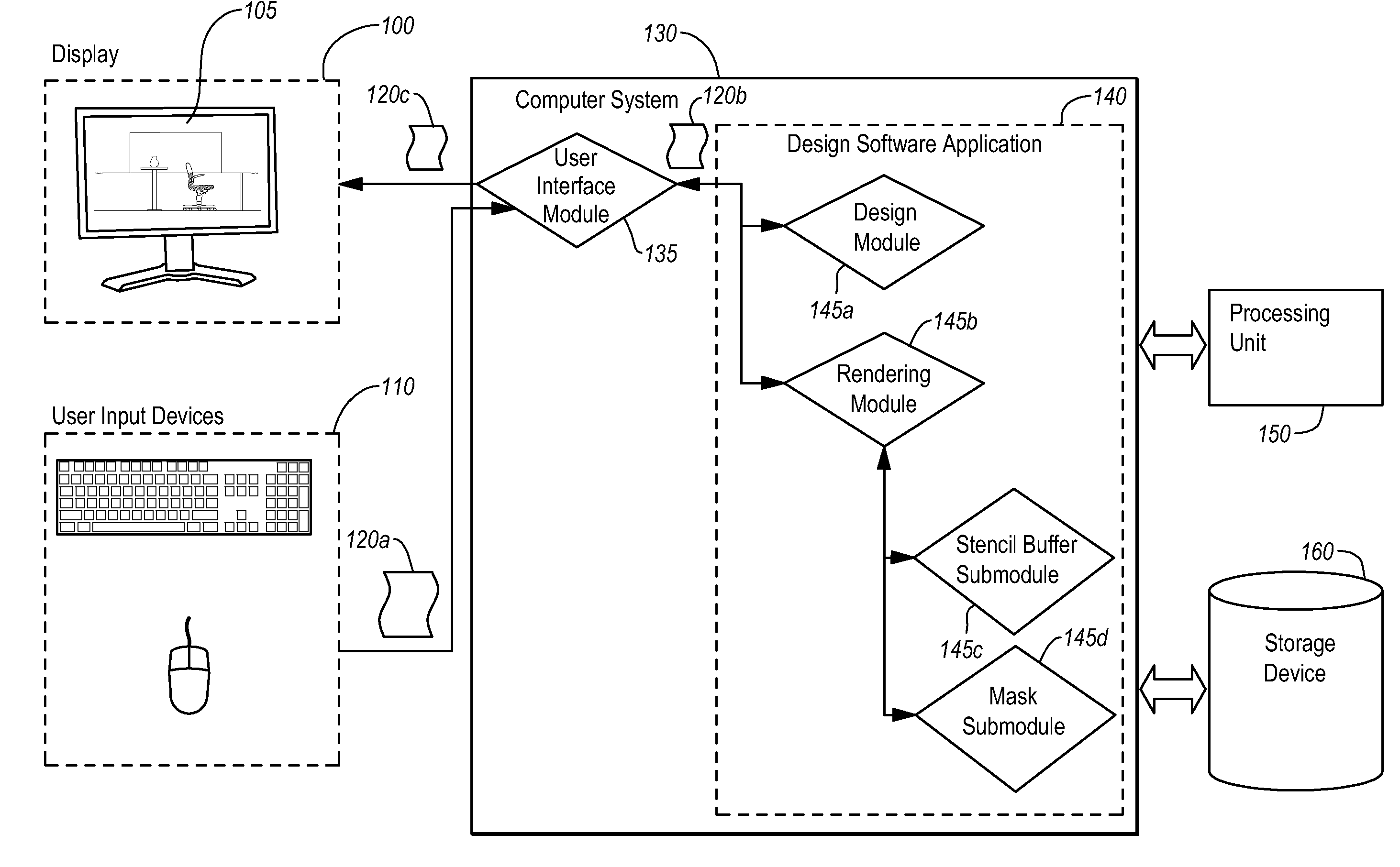

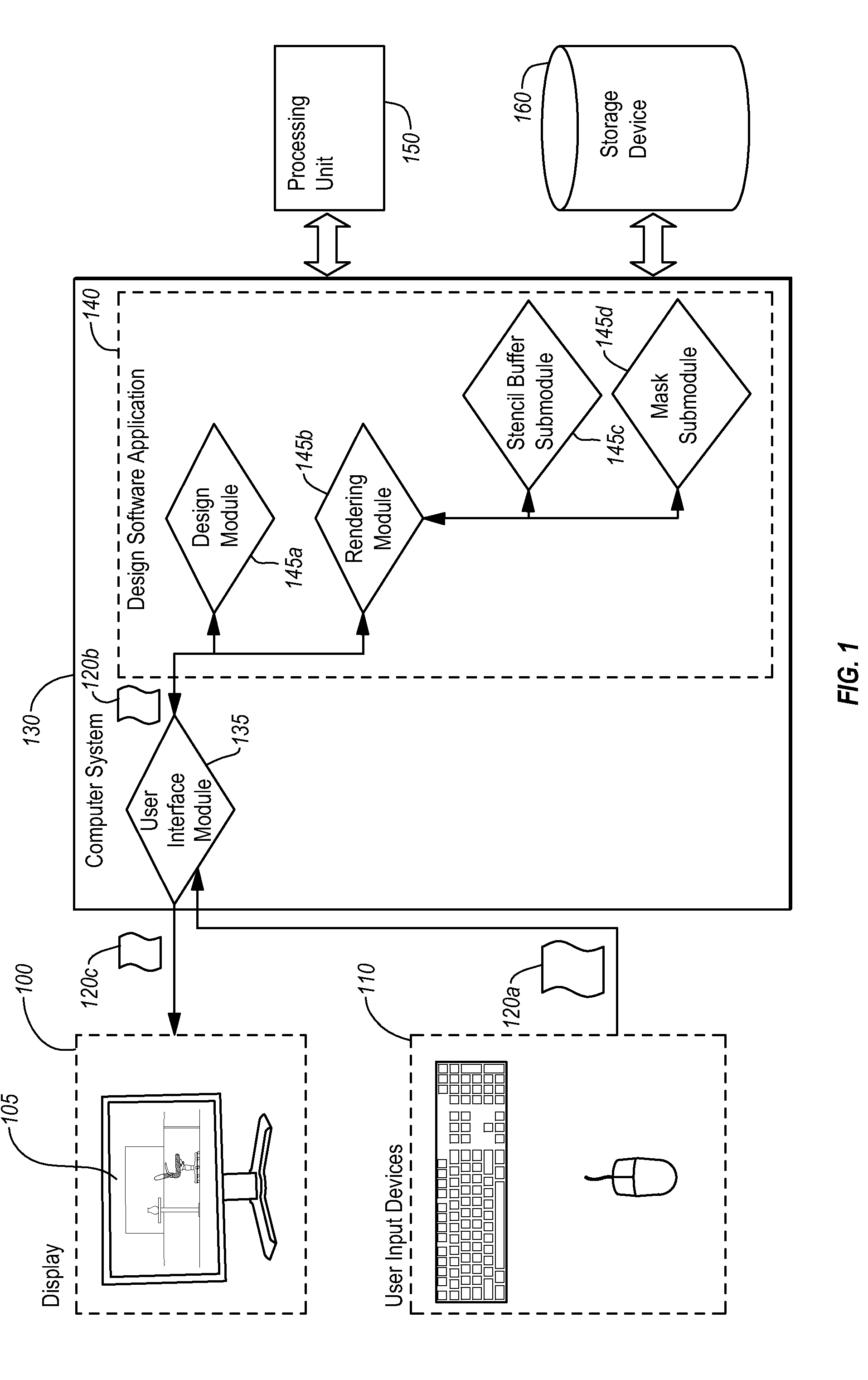

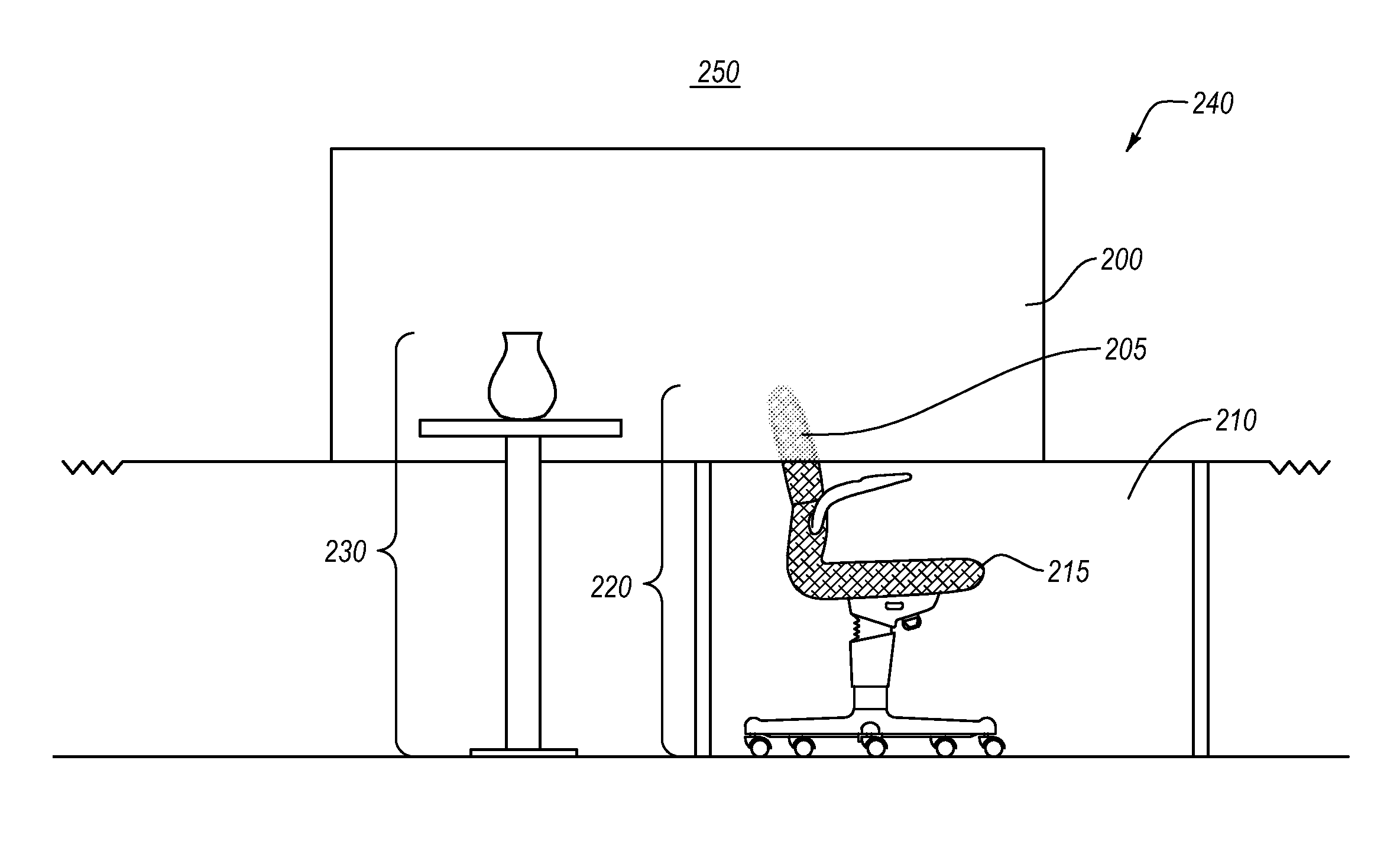

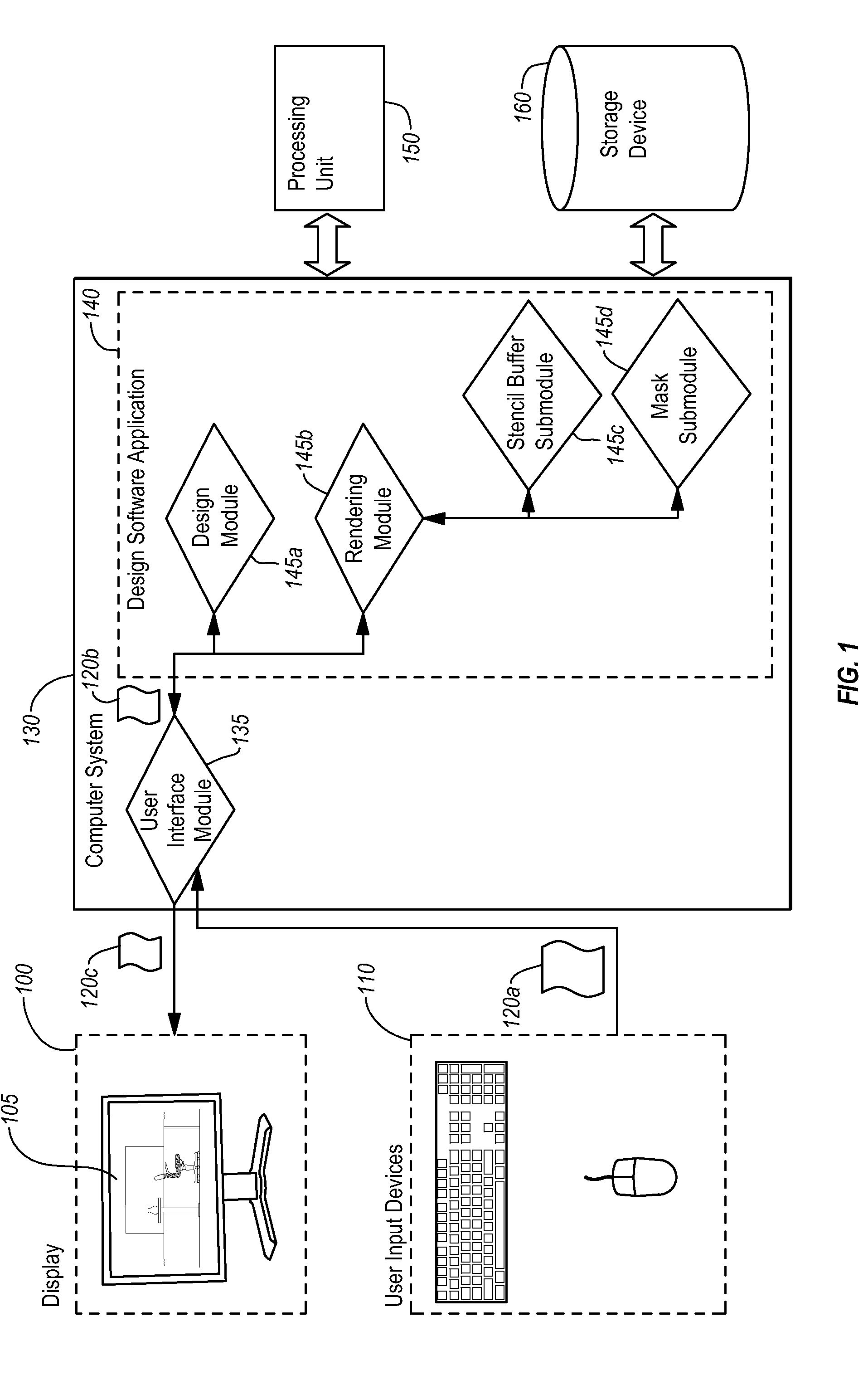

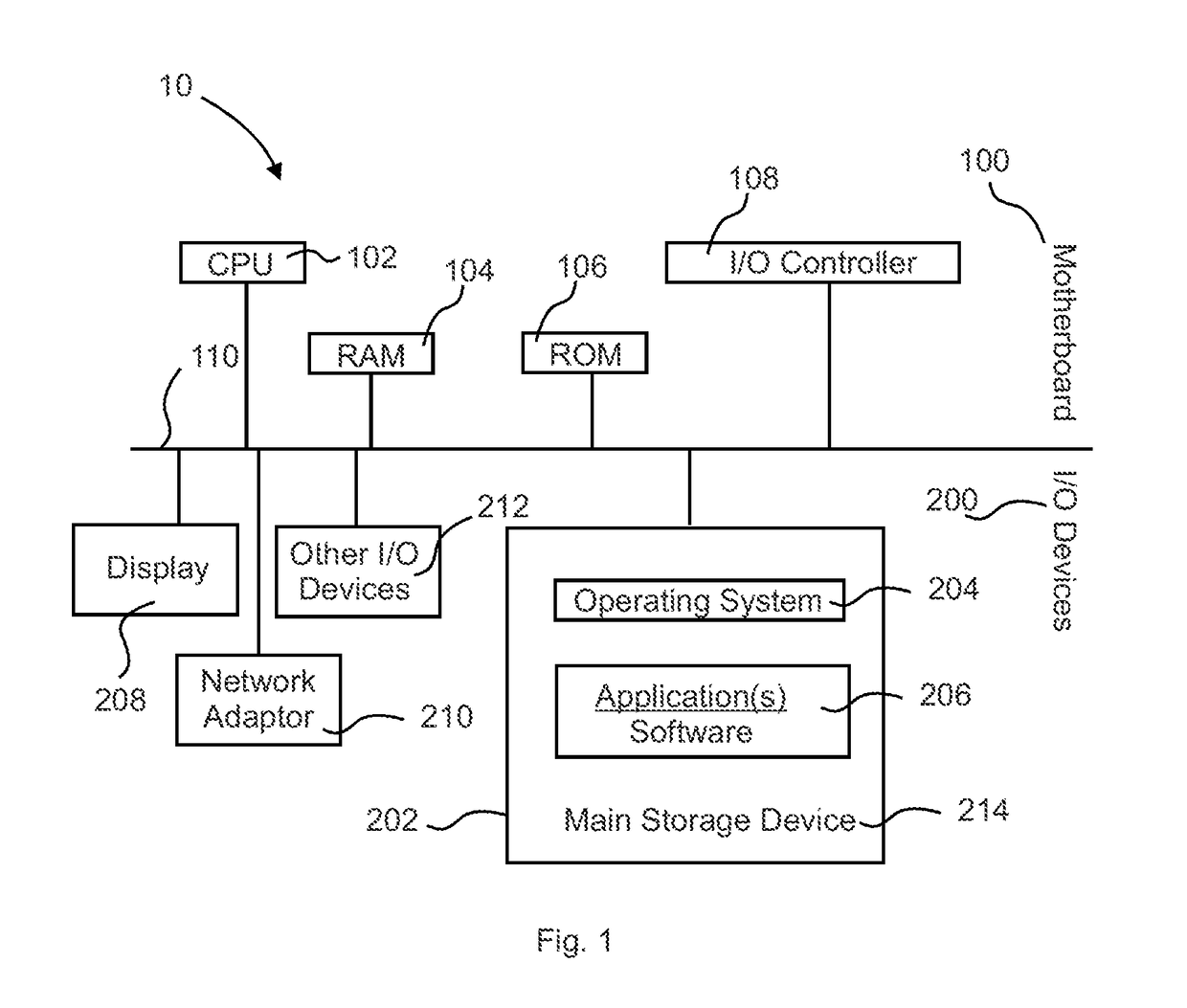

Visual distoration effects through translucent structures in design software

ActiveUS20140362075A1Realistic effectImage generation3D-image renderingVisual distortionThree dimensional model

System, methods, and apparatus allow for creating translucent surfaces within a three-dimensional model. One or more implementations render a three-dimensional model of a layout of a design space within an architectural design environment. Additionally, one or more implementations identify a first portion of the three-dimensional model that is positioned behind a translucent surface within the three-dimensional model. Furthermore, one or more implementations render a visual distortion effect for the identified first portion of the three-dimensional model. Further still, one or more implementations display on a display device the three-dimensional model comprising the translucent surface, such that the three-dimensional model is displayed behind the translucent surface in a distorted form based on the rendered distortion effect.

Owner:ICE EDGE BUSINESS SOLUTIONS

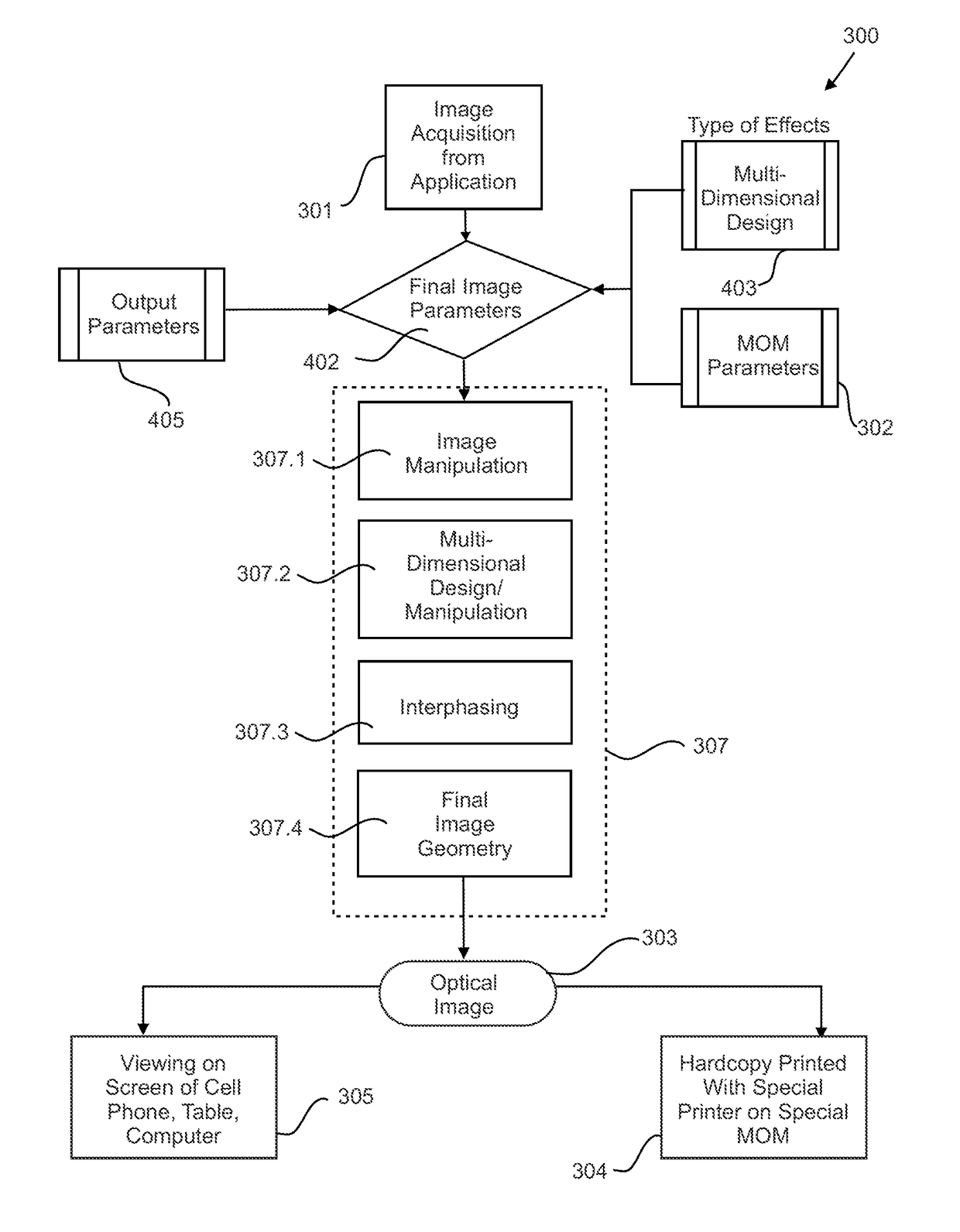

Digital multi-dimensional image photon platform system and methods of use

ActiveUS20160227184A1Quality improvementOvercome problemsAdditive manufacturing apparatusPattern printingParallaxOutput device

A systematic approach to producing multi-dimensional photon images on a computer platform having applications to input image(s) from various sources, and applications to coordinate and adjust numerous variables which determine the quality of the image, such as the size of the imported images, the output image size, the resolving power of the viewing screen and the width of the resolving elements, the dots per inch of the output device (or pixels per inch), the desired nearest object, the desired furthest object and the determination of the central or the “key subject”, rules of interphasing, the number of frames or layers, the minimum parallax, and the maximum parallax, and, thus, provide a digital multi-dimensional image without jumping images or fuzzy features or other visual distortions by creating high quality output images both in the form of a printed hardcopy or as a viewed image on an appropriate viewing device.

Owner:NIMS JERRY +2

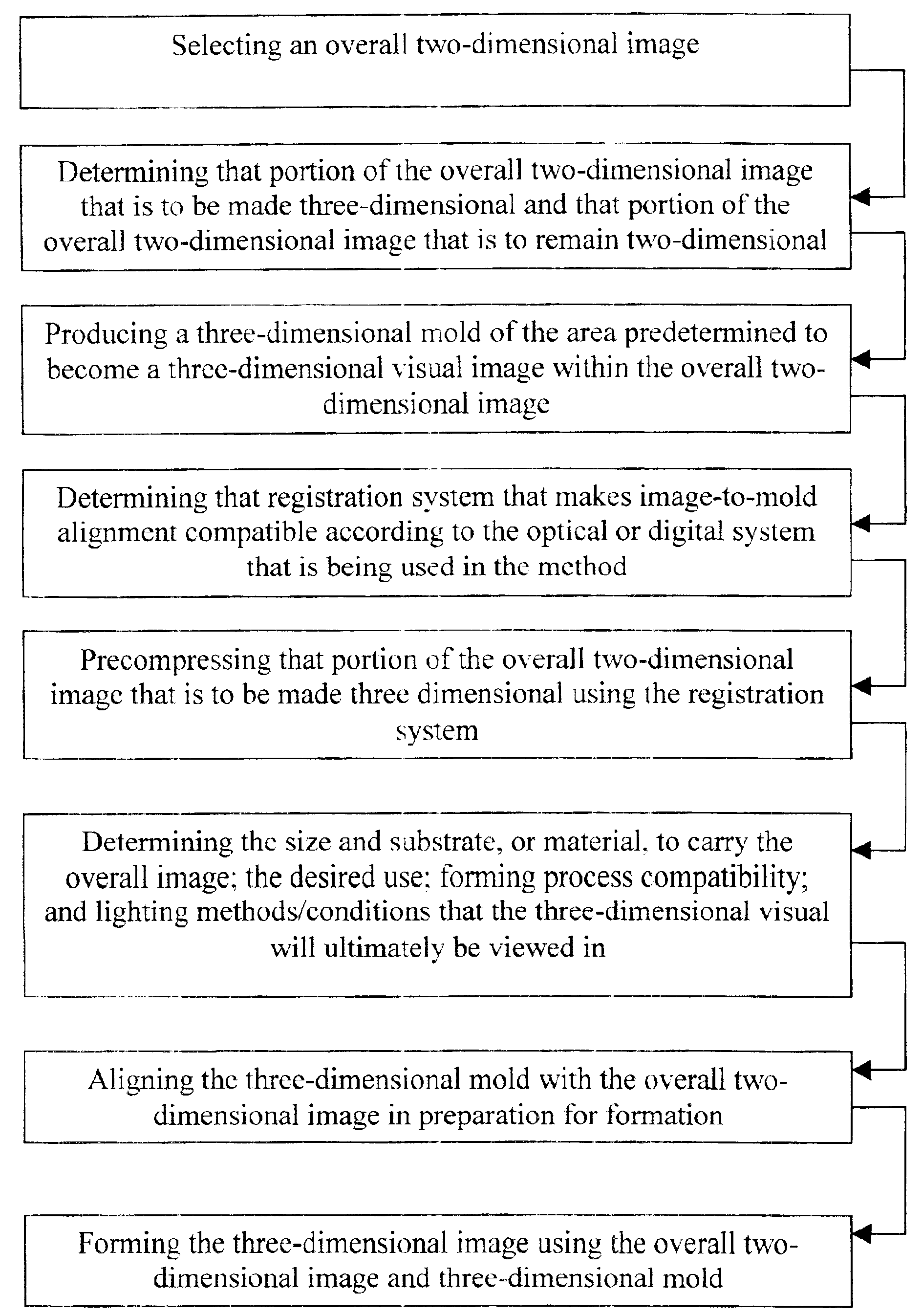

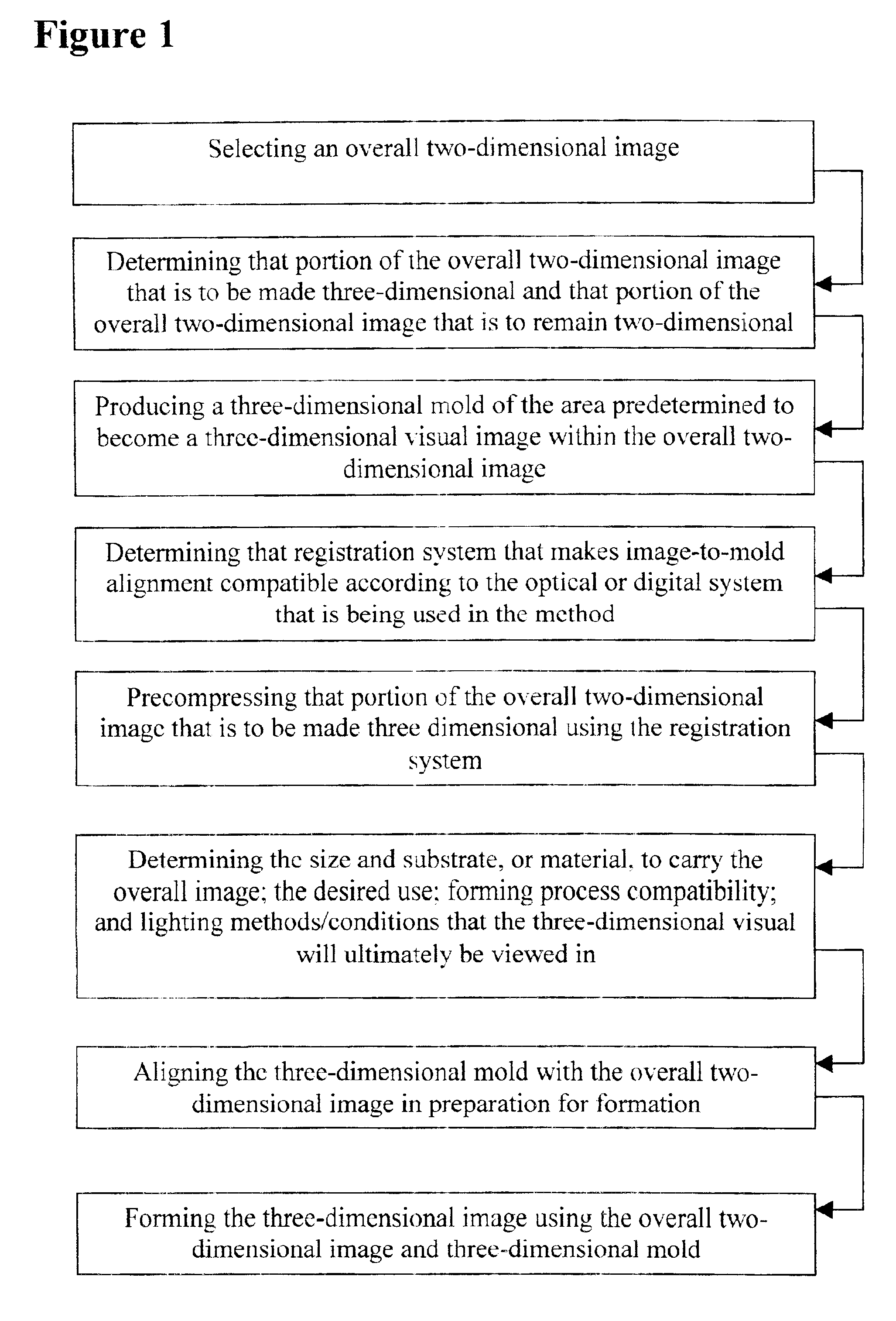

Method for producing quasi-three dimensional images

InactiveUS6916436B2Increase awarenessEnhance interestMeasurement devicesDecorative surface effectsSingle imageComputer science

A method to transform any portion of a two-dimensional visual image into a three-dimensional formed visual image device within the overall two-dimensional visual areas on a single image piece is provided. The resultant image has both two-dimensional and three-dimensional aspects in the same single image piece, or visual device. Furthermore, the present invention provides a method that offers fall control of the amount of visual distortion involved in the above processes.

Owner:TARABULA MICHAEL

Stereoscopic image redirecting method

The invention relates to a stereoscopic image redirecting method which comprises: firstly establishing an energy equation according to the texture similarity and parallax similarity of pixels; establishing a cost matrix M according to the established energy equation and selecting a line with the lowest energy cost by dynamic programming; combining depth information with a plane saliency map to obtain a stereoscopic saliency map; performing spatial coherence filtering on the saliency map to obtain a final importance image IM; allocating a scaling factor to a left view; finding out a corresponding relation between the pixels in the left view and a right view according to theparallax of left and right views, and obtaining the scaling factor of the pixels of the right view; according to the scaling factor of each, redirecting the image by using a pixel fusion algorithm to obtain a final redirected image. The stereoscopic image redirecting method can reduce visual distortion.

Owner:TIANJIN UNIV

Dual-color image blind watermarking method based on QR decomposition and compensation

InactiveCN103617591AThe method is simple and fastHigh watermark invisibilityImage data processing detailsPattern recognitionWatermark method

The invention discloses a dual-color image blind watermarking method based on QR decomposition and compensation, which aims to change the current situation that the current digital watermarking is mostly a binary or grayscale image and meet the requirement that a color digital image serves as digital watermarking. According to the technical key point, color image watermarking is embedded into an orthogonal matrix Q obtained by QR decomposition; visual distortion caused by watermarking embedding is compensated by utilizing a triangular matrix R; and assistance of the original watermarking or the original host image is not needed during watermarking extraction, so that blind detection is realized. The method is simple and quick, has the advantages of high watermarking invisibility, strong robustness and high capacity, and is applicable to copyright protection of the color digital image serving as the digital watermarking.

Owner:LUDONG UNIVERSITY

Visual distortion effects through translucent structures in design software

System, methods, and apparatus allow for creating translucent surfaces within a three-dimensional model. One or more implementations render a three-dimensional model of a layout of a design space within an architectural design environment. Additionally, one or more implementations identify a first portion of the three-dimensional model that is positioned behind a translucent surface within the three-dimensional model. Furthermore, one or more implementations render a visual distortion effect for the identified first portion of the three-dimensional model. Further still, one or more implementations display on a display device the three-dimensional model comprising the translucent surface, such that the three-dimensional model is displayed behind the translucent surface in a distorted form based on the rendered distortion effect.

Owner:ARMSTRONG WORLD IND INC

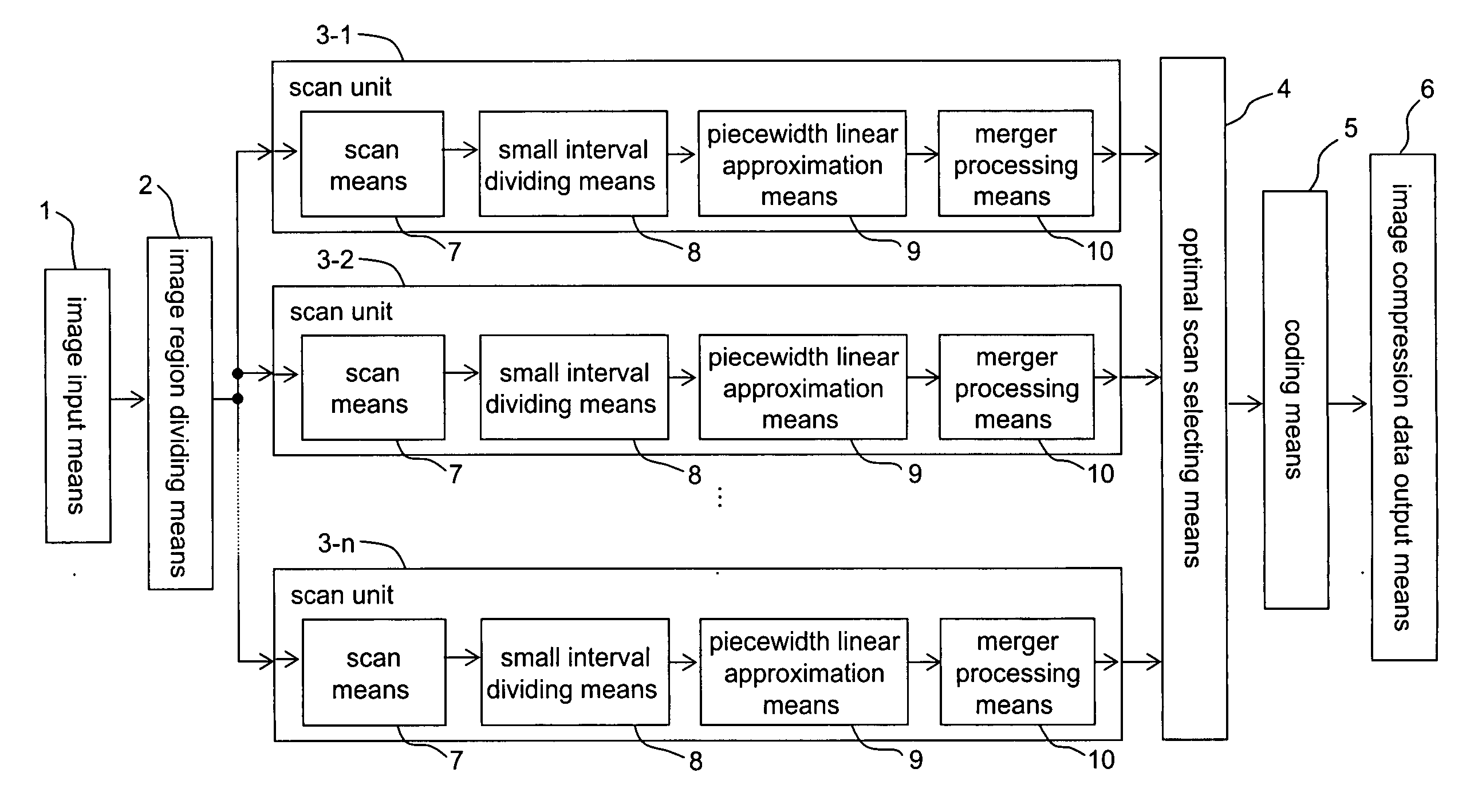

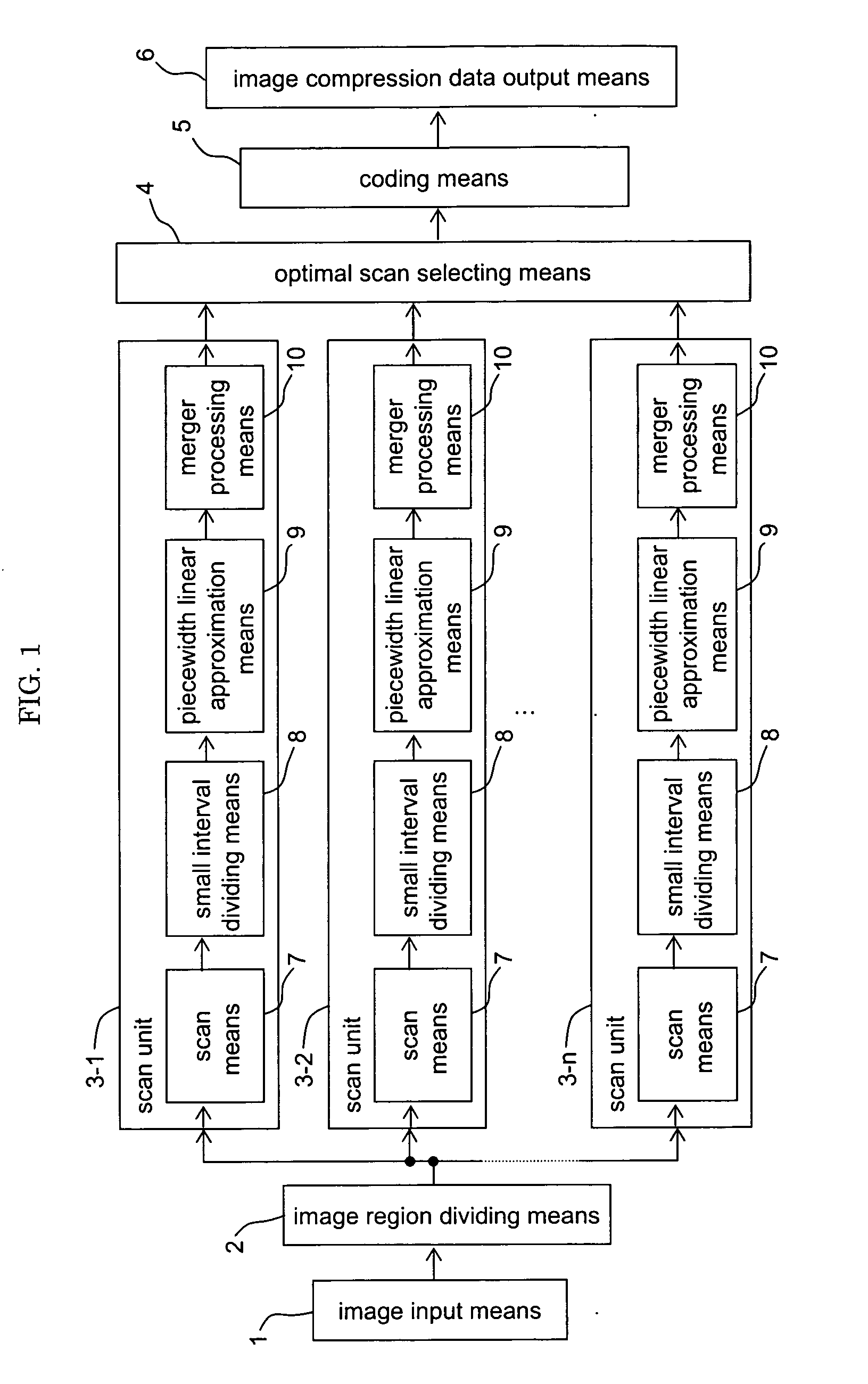

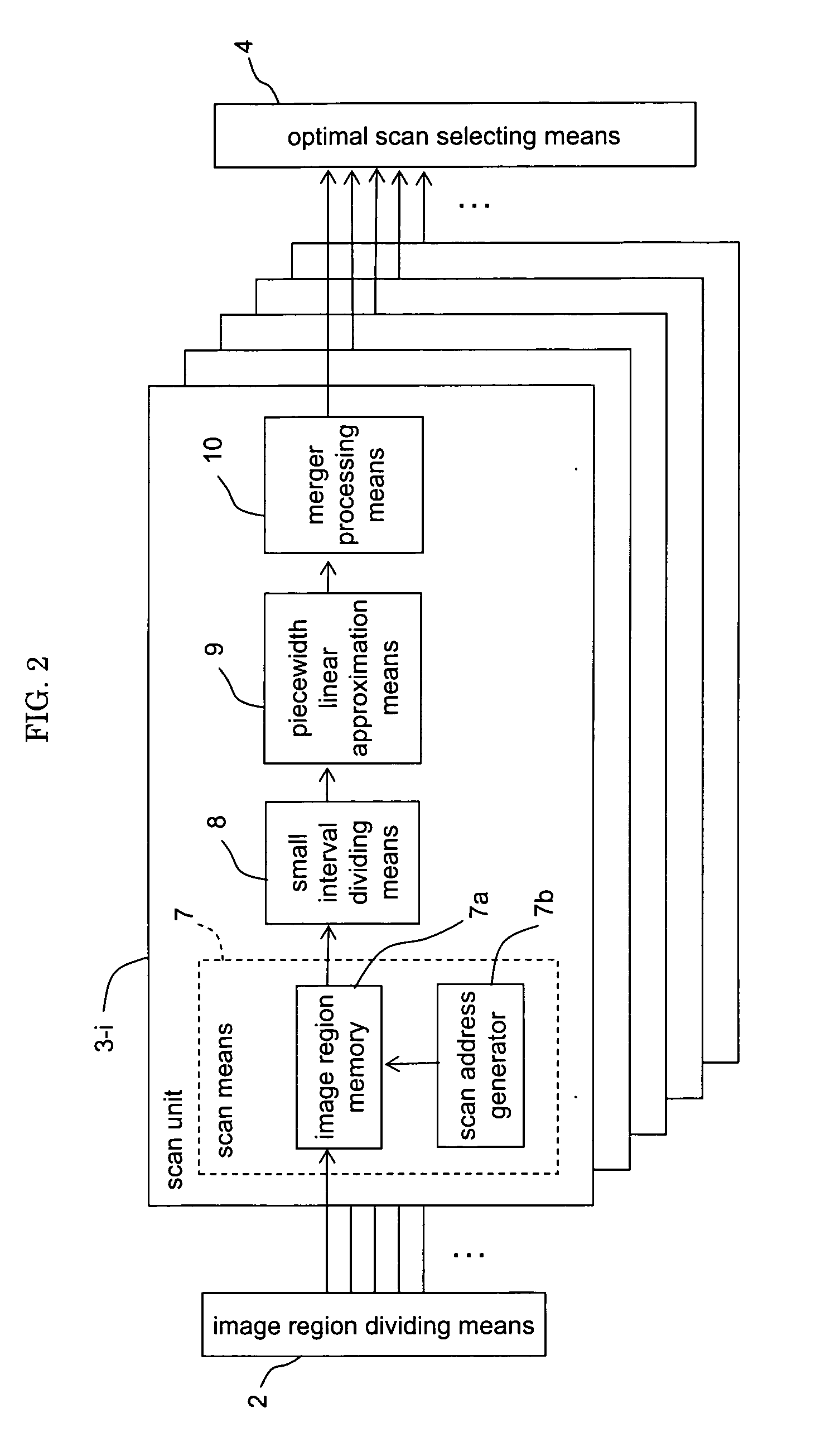

Apparatus and method for image coding

InactiveUS20070098271A1High speed machiningLess distortionCharacter and pattern recognitionSensing record carriersComputer graphics (images)Image segmentation

Provided is an image coding technique capable of realizing a high speed coding processing for a mixed image with less of a visual distortion. The image coding apparatus includes: plural scan units 3 each having scan means 7 scanning an original image to be encoded according to a prescribed scan sequence and piecewidth linear approximation means 9 dividing a one-dimensional original image generated by scanning the original image with the scan means 7 into plural intervals so that accumulated square error or a dispersion of pixel values in each interval is a prescribed threshold value or less to generate one-dimensional approximation image data obtained by approximation of pixel values by the average value of pixel values in the intervals, which correspond to each of plural scan sequences different from one another; and optimal scan selecting means 4 comparing the numbers of intervals obtained by dividing of the piecewidth linear approximation means 9 of the scan units 3 to thereby select one dimensional approximation image data having a minimum number of intervals.

Owner:KITAKYUSHU FOUND FOR THE ADVANCEMENT OF IND

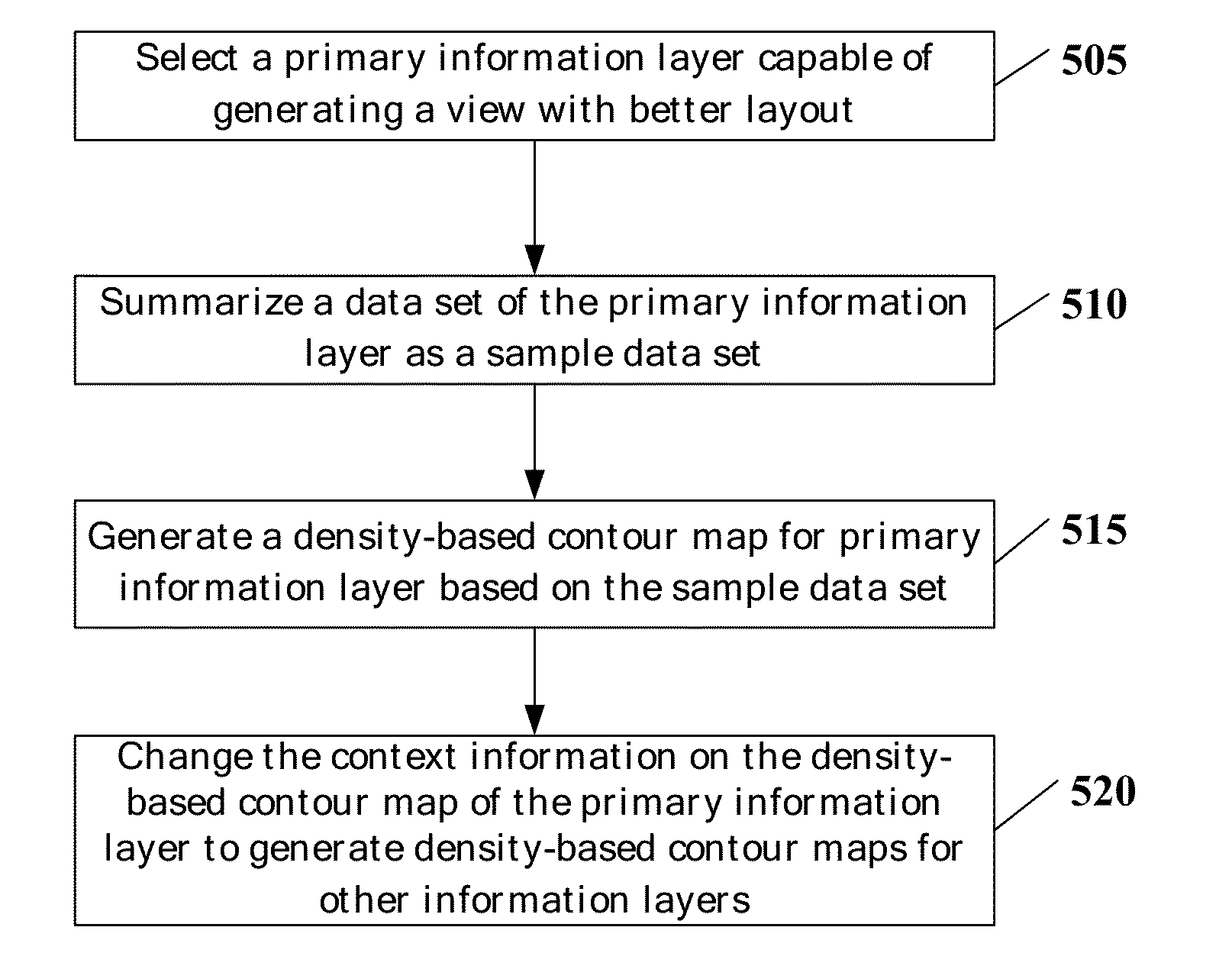

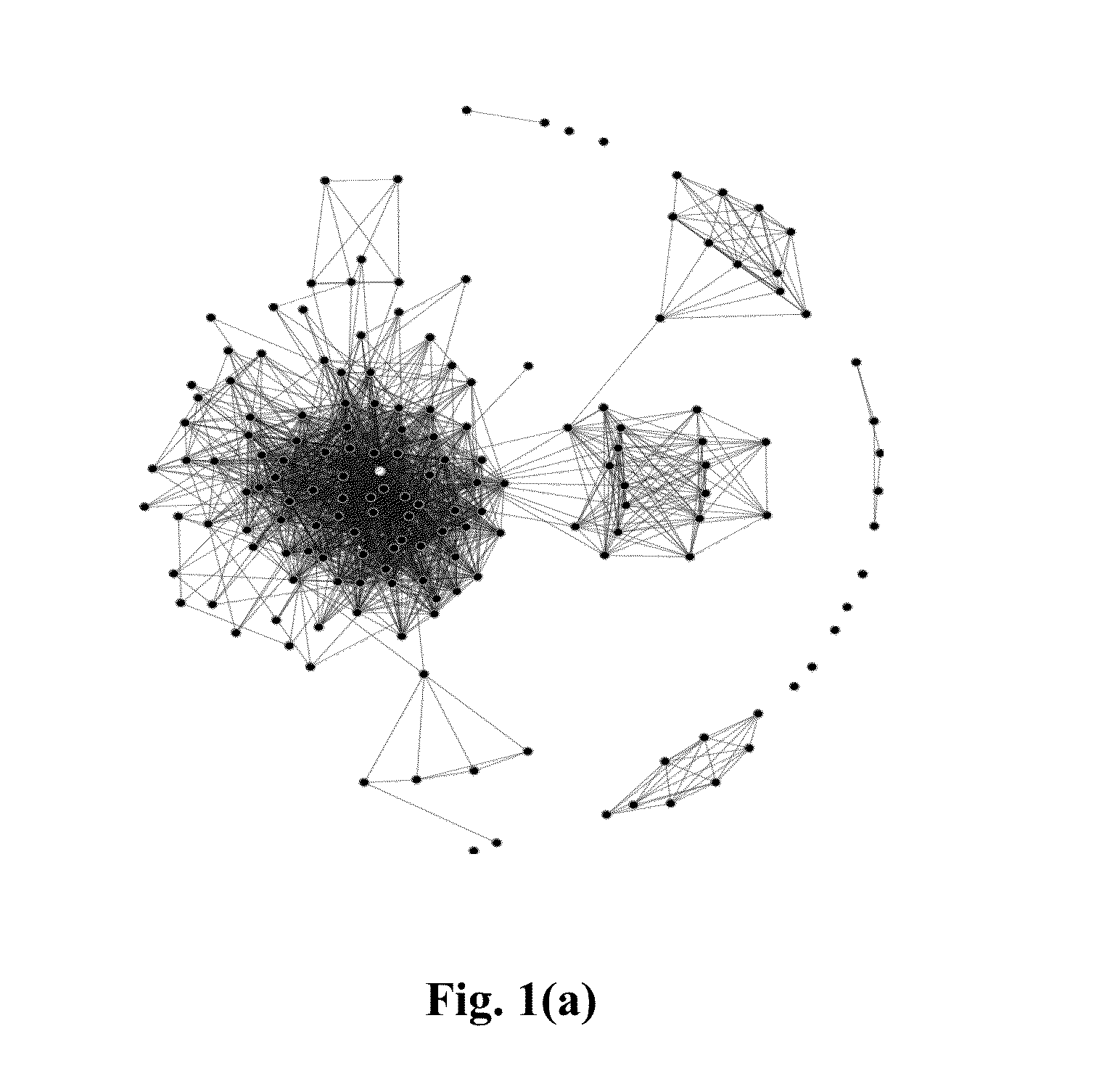

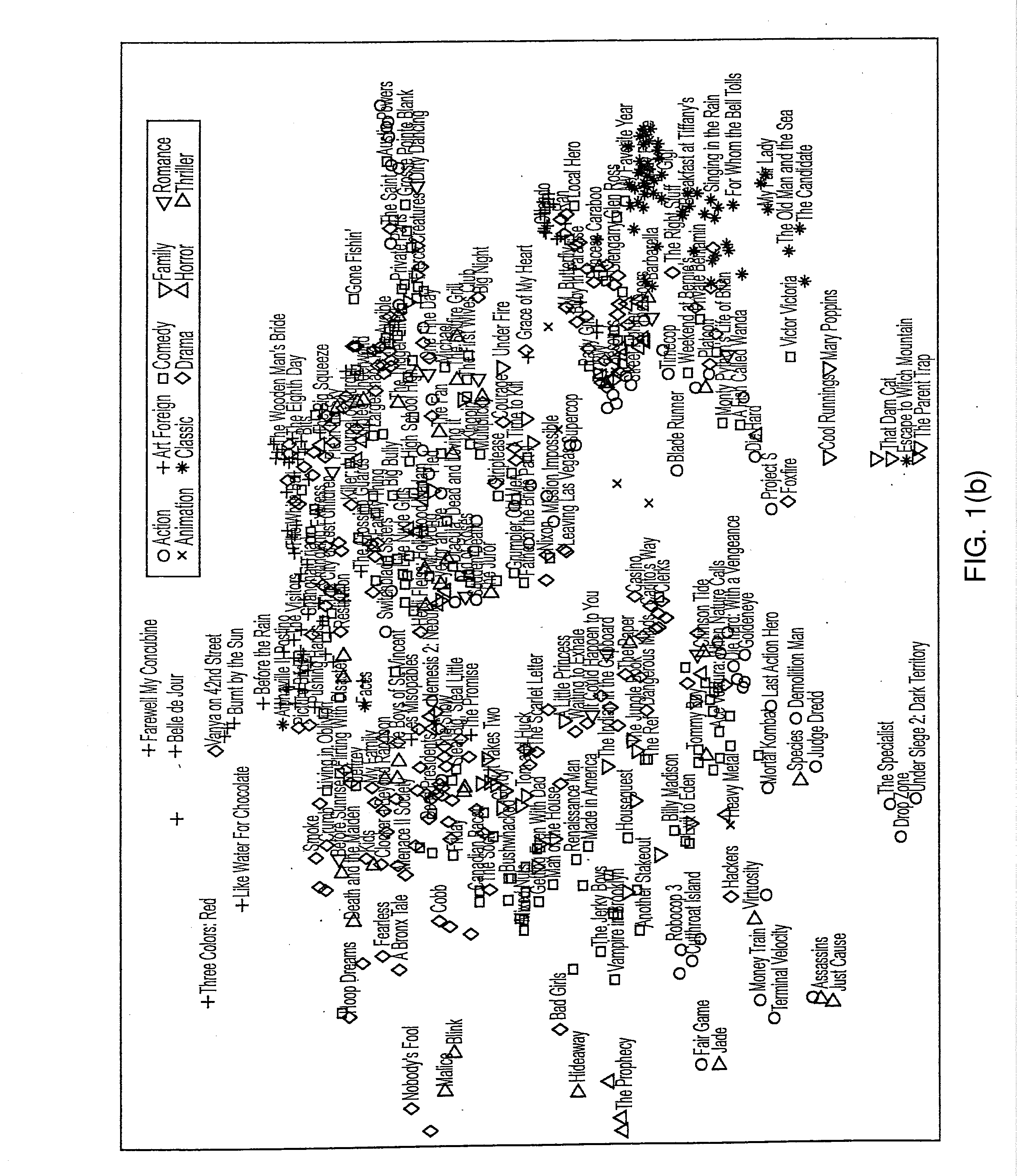

Method and system for visualization of data set

InactiveUS20140082024A1Avoid distortionDigital data processing detailsVisual data miningInformation layerData set

The invention provides a method and system for visualization of a data set, the method comprises: dividing the data set into a plurality of information layers based on different information dimensions; and visually processing the plurality of information layers based on different information dimensions, respectively, in order to present respective views of the plurality of information layers. In the present invention, by visualizing the data set through presenting different overviews of the data set from different information dimensions, respectively, the presentation of comprehensive information of the data set to a data set analyst is ensured while distortion of presented contents as well as visual clutter are prevented.

Owner:IBM CORP

Techniques for aligning frame data

InactiveUS8823721B2Television system detailsColor signal processing circuitsDisplay deviceComputer vision

Owner:INTEL CORP

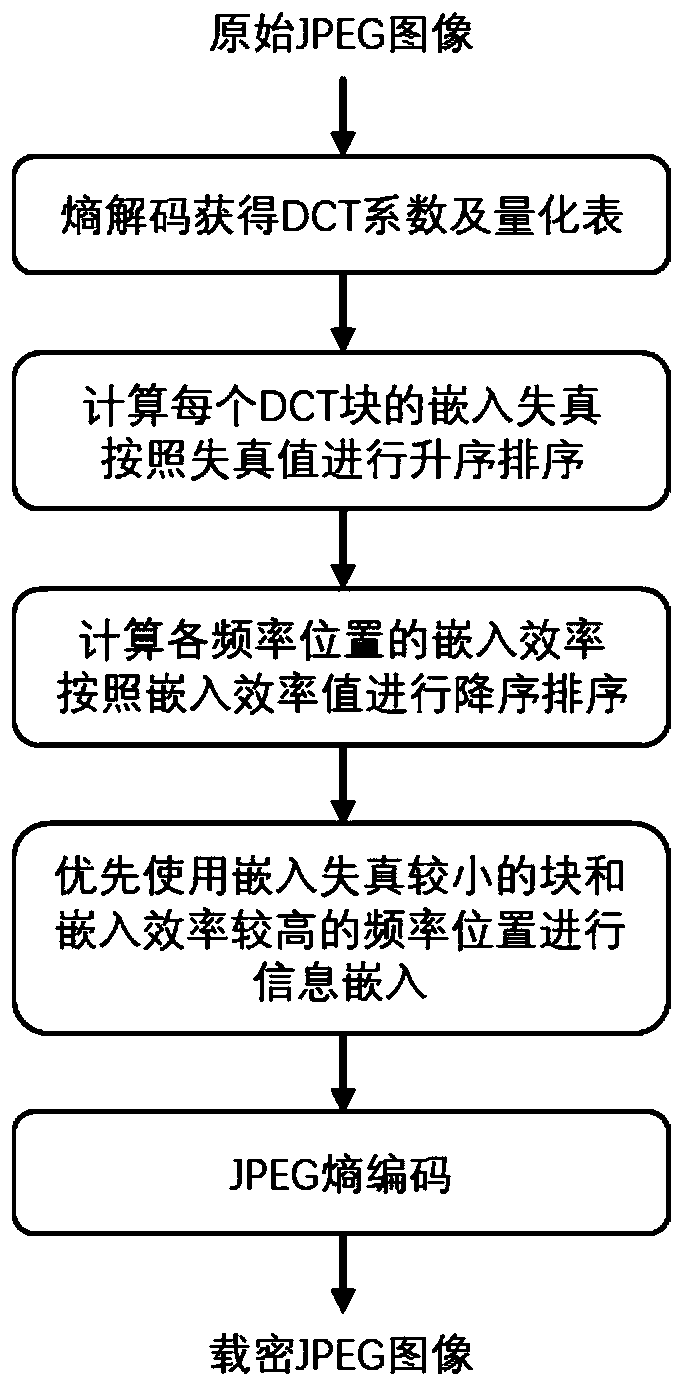

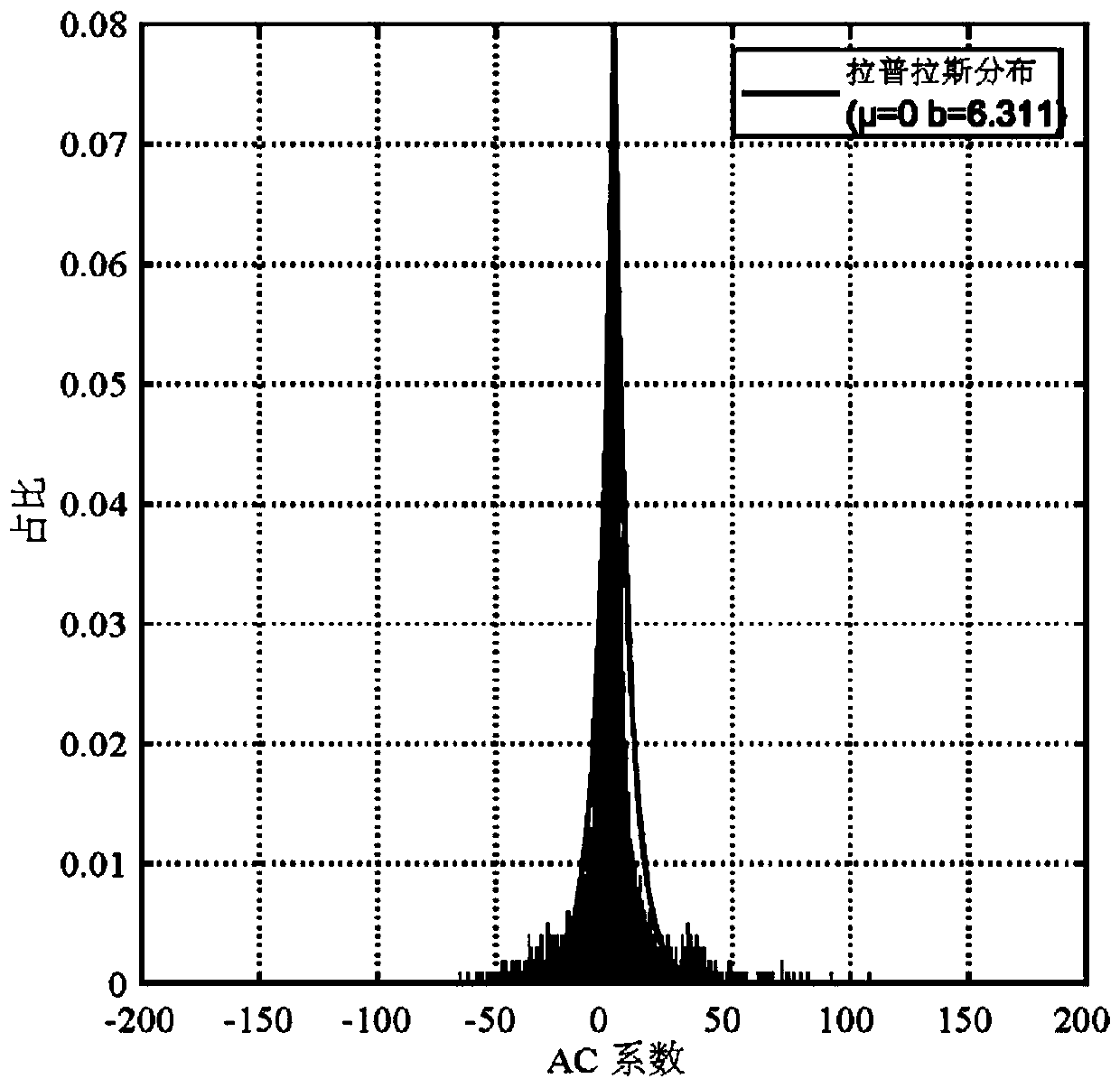

JPEG image reversible information hiding method

ActiveCN110933438AReduce visual distortionReduce recordsDigital video signal modificationInformation embeddingJPEG

The invention discloses a JPEG image reversible information hiding method. The method includes: carrying out entropy decoding on the original JPEG image, converting DCT image, and obtaining a quantized DCT coefficient and a quantized table; calculating an embedded distortion value of each DCT block; carrying out information embedding on the DCT block, wherein the embedding sequence is that embedding distortion values are embedded from small to large; and carrying out entropy coding on the modified DCT coefficient, and obtaining a secret-carrying JPEG image. According to the method, the DCT blocks are selected and reversible information hiding is carried out according to distortion value sorting, so that the visual distortion of the secret-carrying JPEG image is effectively reduced.

Owner:SOUTH CHINA UNIV OF TECH

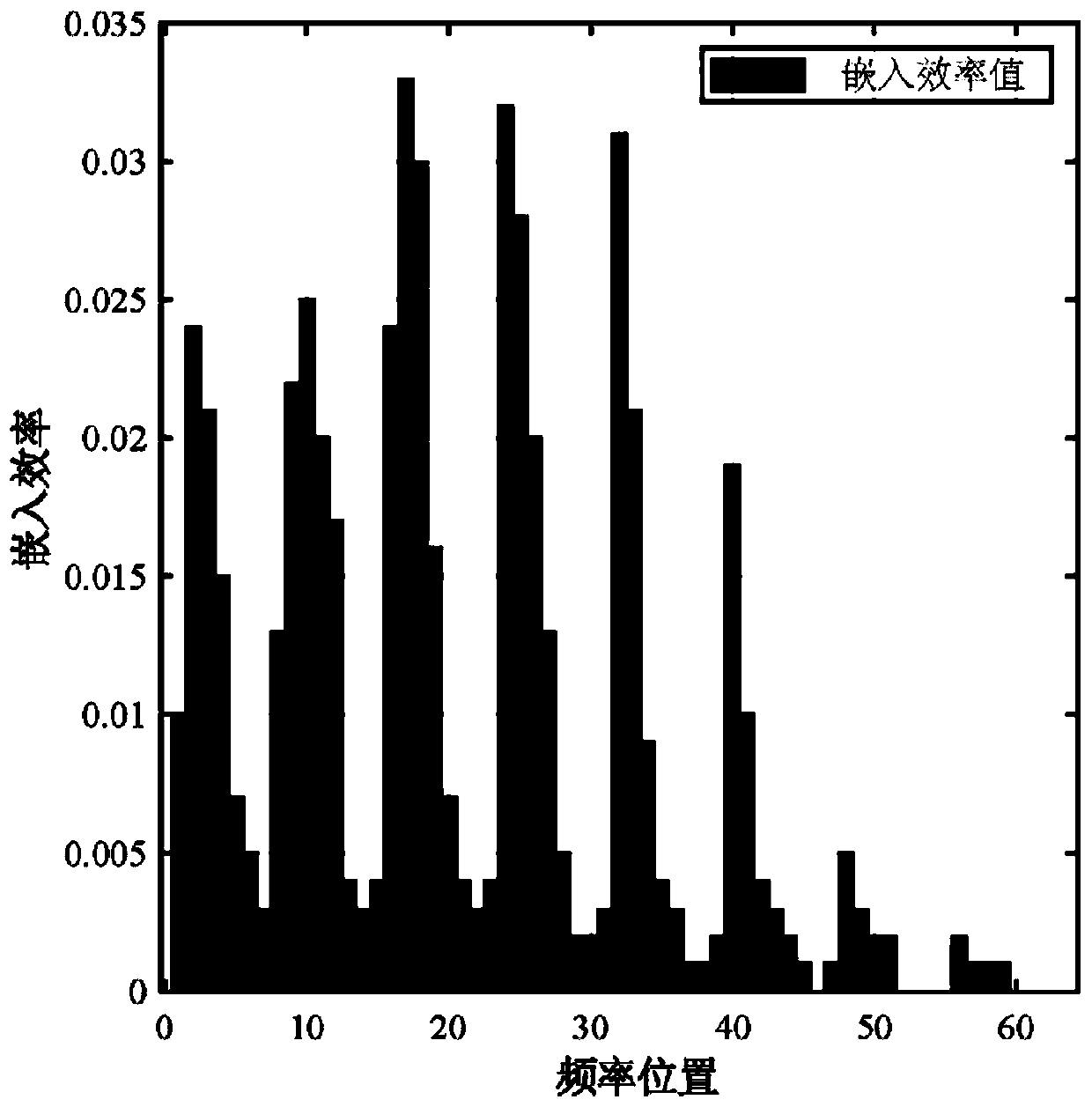

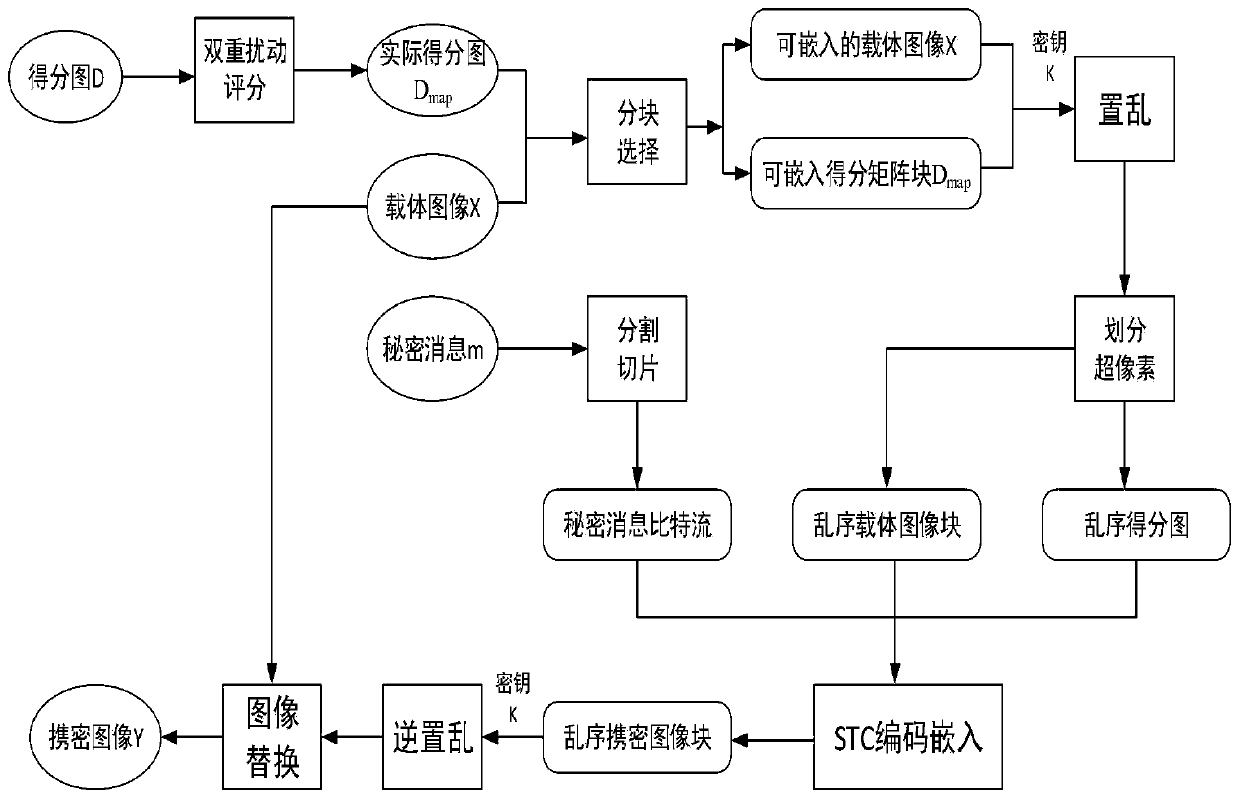

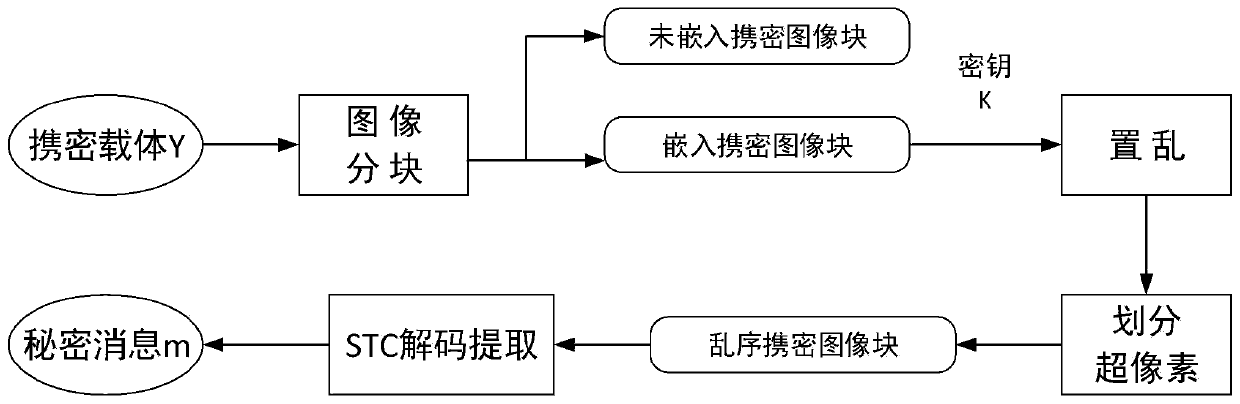

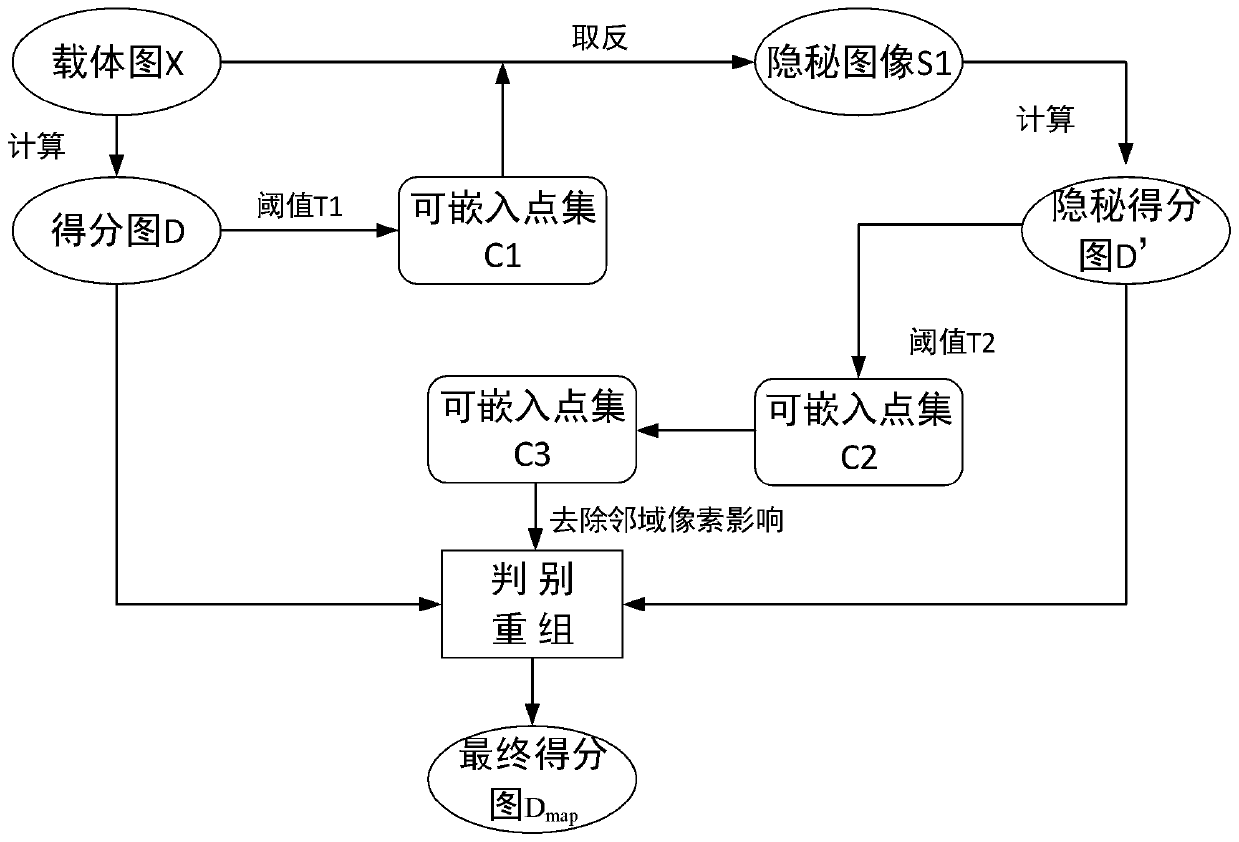

Information steganography algorithm of binary image double disturbance scoring based on STC coding

ActiveCN109963159ALow embedding distortionGood visual quality of imagesDigital video signal modificationAlgorithmImaging quality

The invention provides a binary image double disturbance scoring information steganography algorithm based on STC coding. According to the algorithm, disturbance scoring is conducted on an image through an improved crmiLTP distortion measurement method, the influence of pixel point overturning before steganography and pixel point overturning after steganography on a disturbance mapping graph is considered, secret information is embedded through efficient STC coding on the basis of block hiding, and finally the steganography algorithm small in visual distortion and high in safety is designed. According to the invention, the carrier image property is considered; a double disturbance scoring criterion is set, bidirectional evaluation analysis is carried out on reversible points of an image edge area, and STC coding is combined, so that the algorithm has high image quality, small visual distortion and certain anti-steganography analysis and detection performance, and has a very large effect on secure secret communication.

Owner:SUN YAT SEN UNIV

Digital multi-dimensional image photon platform system and methods of use

ActiveUS10178247B2Quality improvementOvercome problemsOptical articlesStereoscopic photographyOutput deviceMulti dimensional

Owner:NIMS JERRY +2

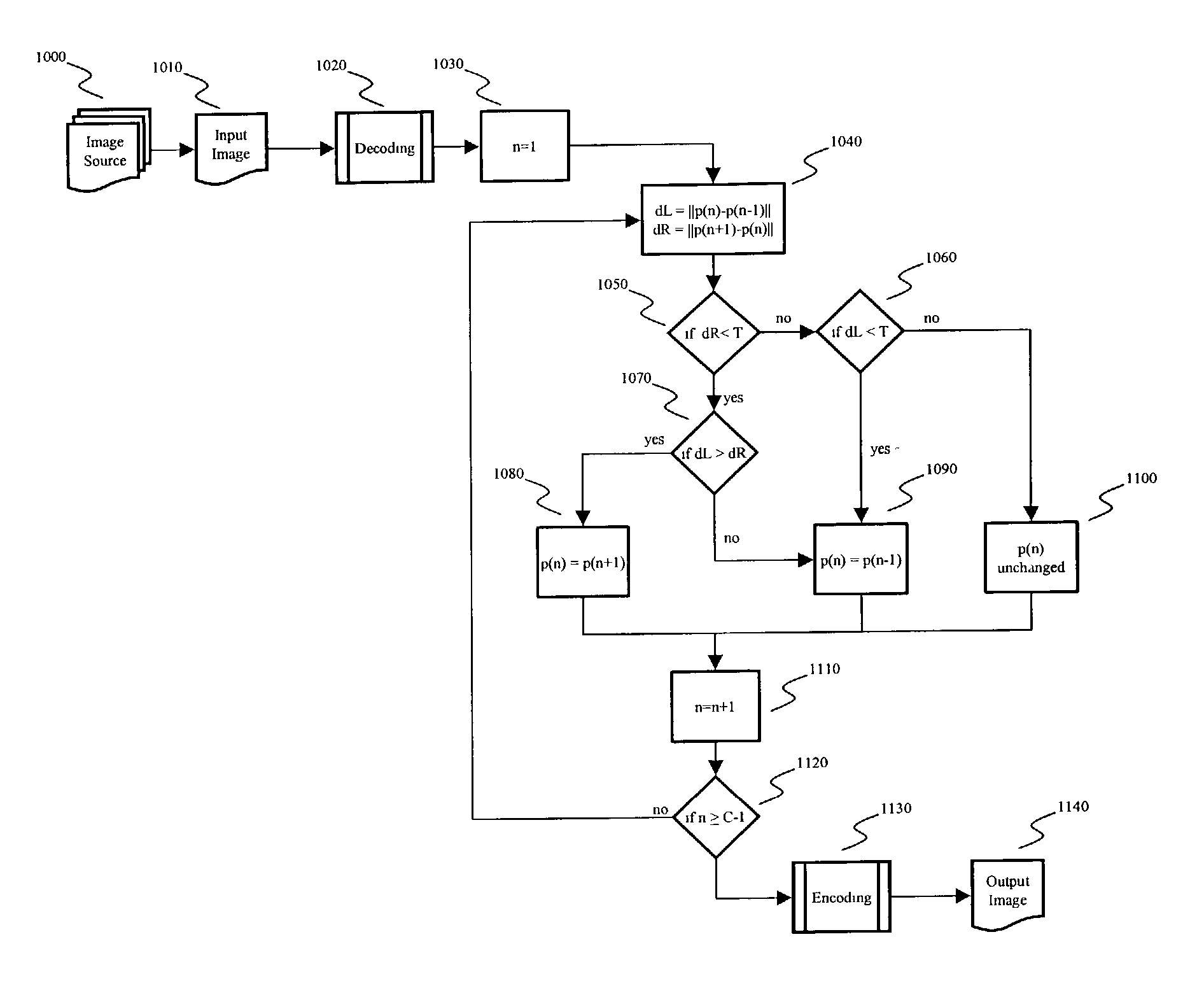

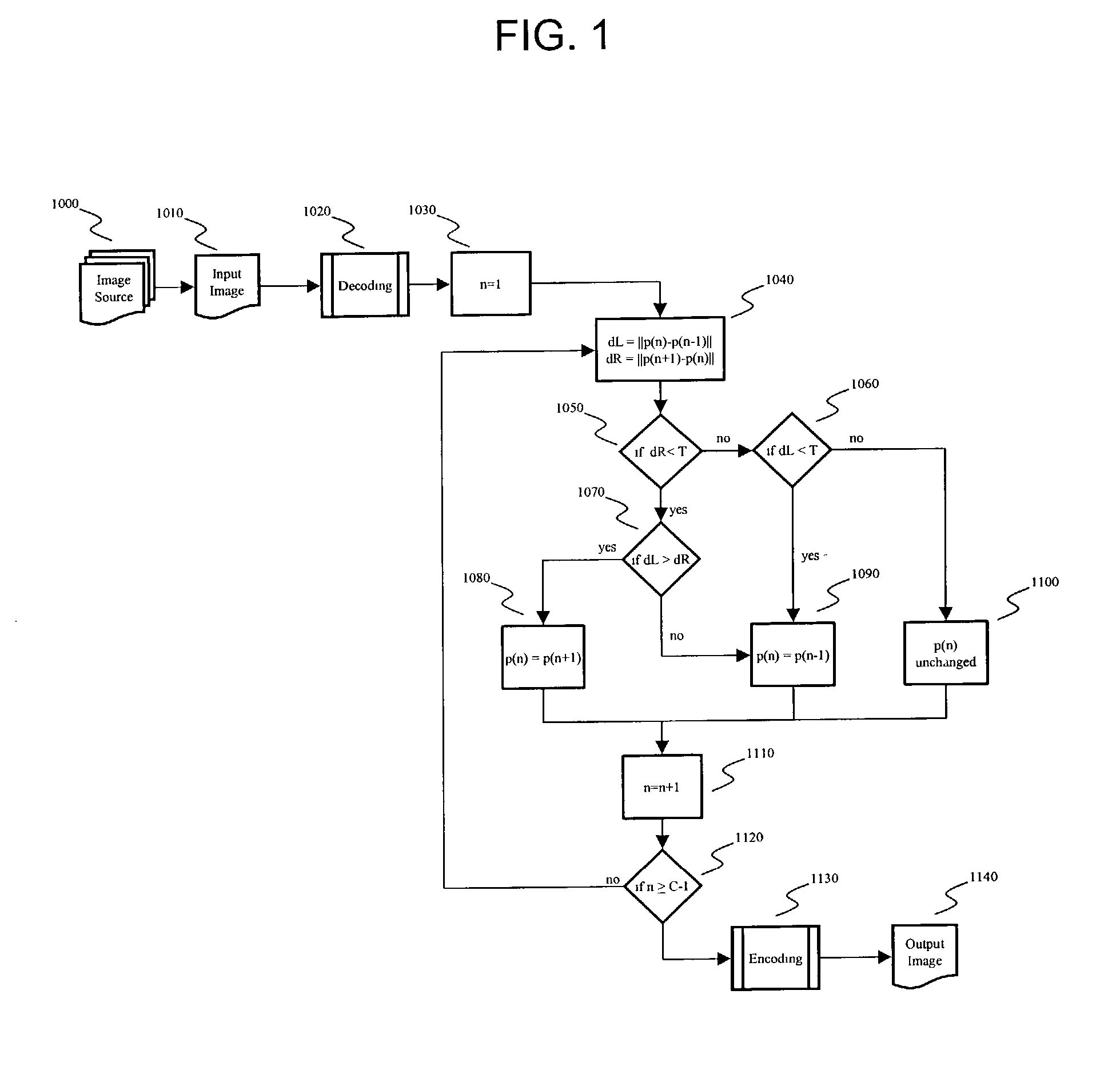

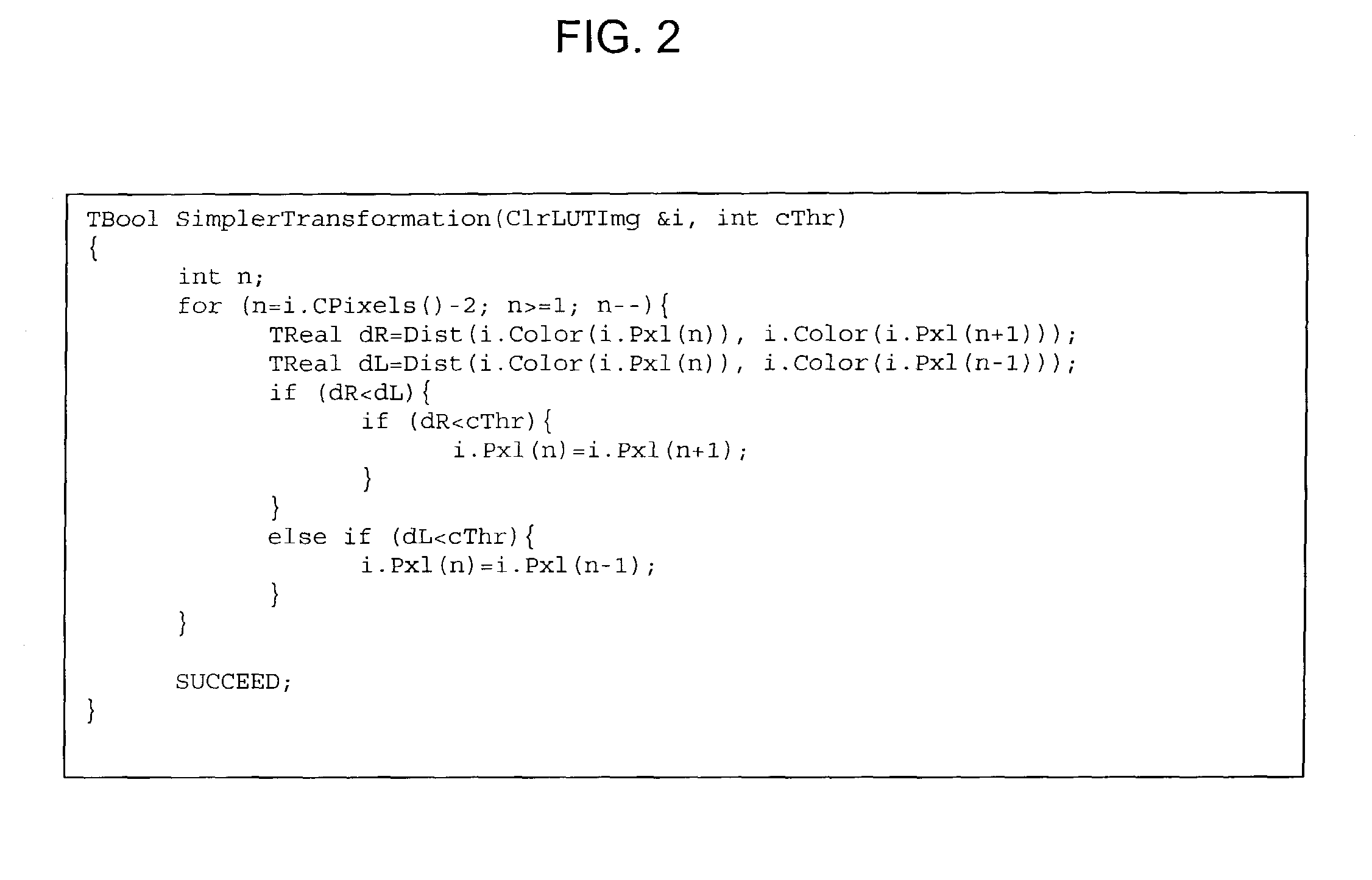

Transformation to increase the lempel-ziv compressibility of images with minimal visual distortion

ActiveUS7031540B2Improve compression performanceIncreases length and frequencyCode conversionImage codingCompressibilityDigital image

A transformation system for increasing the compressibility of digital images. In one embodiment, the pixels of a digital image are examined, one at a time. The color of the examined pixel is compared to that of its neighbors. If the difference in color from either of the neighboring pixels is below a threshold, the color of the neighbor that is closer to the color of the examined pixel is copied to the examined pixel. If neither of the neighbors is close enough in color, the color of the examined pixel is unchanged. The pixels are examined in a single pass. After each pixel has been examined, and possibly changed, the compressibility of the image using a dictionary-based technique, such as one of the Lempel-Ziv techniques, is typically improved.

Owner:TIVO CORP

Digital multi-dimensional image photon platform system and methods of use

ActiveUS10033990B2Quality improvementOvercome problemsSteroscopic systems3D modellingOutput deviceVisual perception

A systematic approach to producing multi-dimensional photon images on a computer platform having applications to a plurality of input image(s) from various sources, and applications to coordinate and adjust numerous variables which determine the quality of the image, such as the size of the imported images, the output image size, the resolving power of the viewing screen and the width of the resolving elements, the dots per inch of the output device (or pixels per inch), the desired nearest object, the desired furthest object and the determination of the central or the “key subject”, rules of interphasing, the number of frames or layers, the minimum parallax, and the maximum parallax, and, thus, provide a digital multi-dimensional image without jumping images or fuzzy features or other visual distortions by creating high quality output images both in the form of a printed hardcopy or as a viewed image on an appropriate viewing device. The digital multi-dimensional image platform based system controls the position and path of light from the original object to the human visual system.

Owner:NIMS JERRY +2

Digital multi-dimensional image photon platform system and methods of use

ActiveUS20160227185A1Quality improvementOvercome problemsSteroscopic systemsOutput deviceMulti dimensional

A systematic approach to producing multi-dimensional photon images on a computer platform having applications to a plurality of input image(s) from various sources, and applications to coordinate and adjust numerous variables which determine the quality of the image, such as the size of the imported images, the output image size, the resolving power of the viewing screen and the width of the resolving elements, the dots per inch of the output device (or pixels per inch), the desired nearest object, the desired furthest object and the determination of the central or the “key subject”, rules of interphasing, the number of frames or layers, the minimum parallax, and the maximum parallax, and, thus, provide a digital multi-dimensional image without jumping images or fuzzy features or other visual distortions by creating high quality output images both in the form of a printed hardcopy or as a viewed image on an appropriate viewing device. The digital multi-dimensional image platform based system controls the position and path of light from the original object to the human visual system.

Owner:NIMS JERRY +2

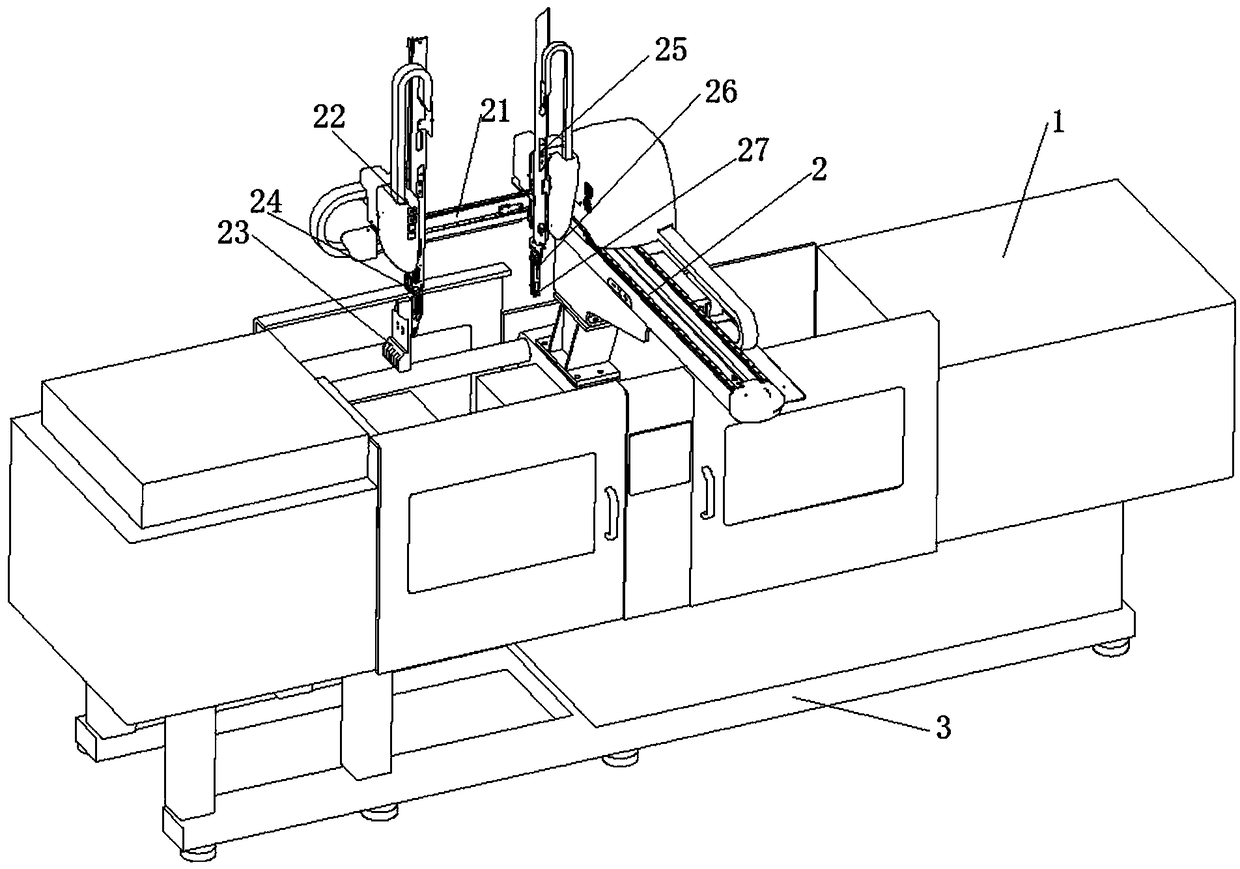

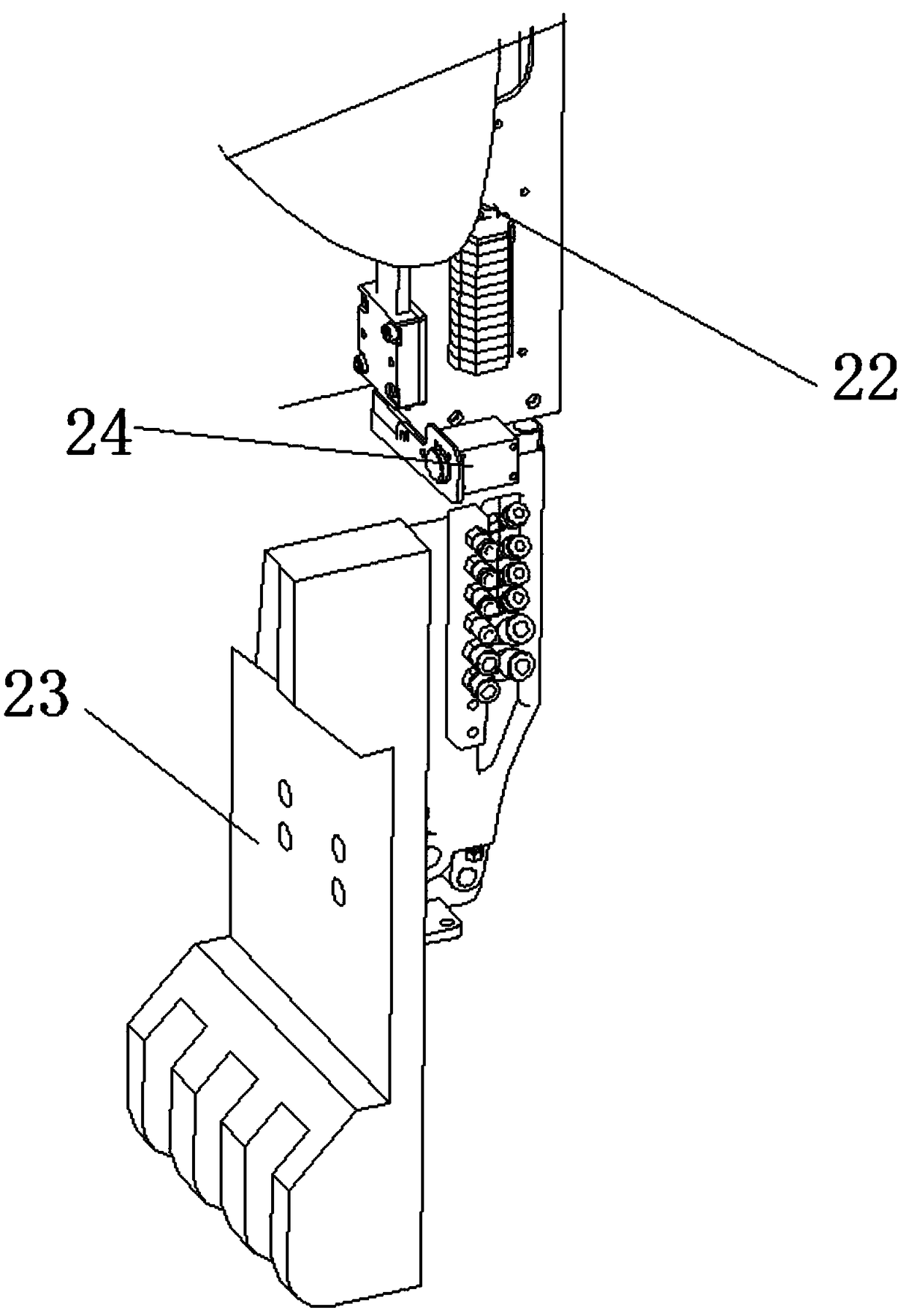

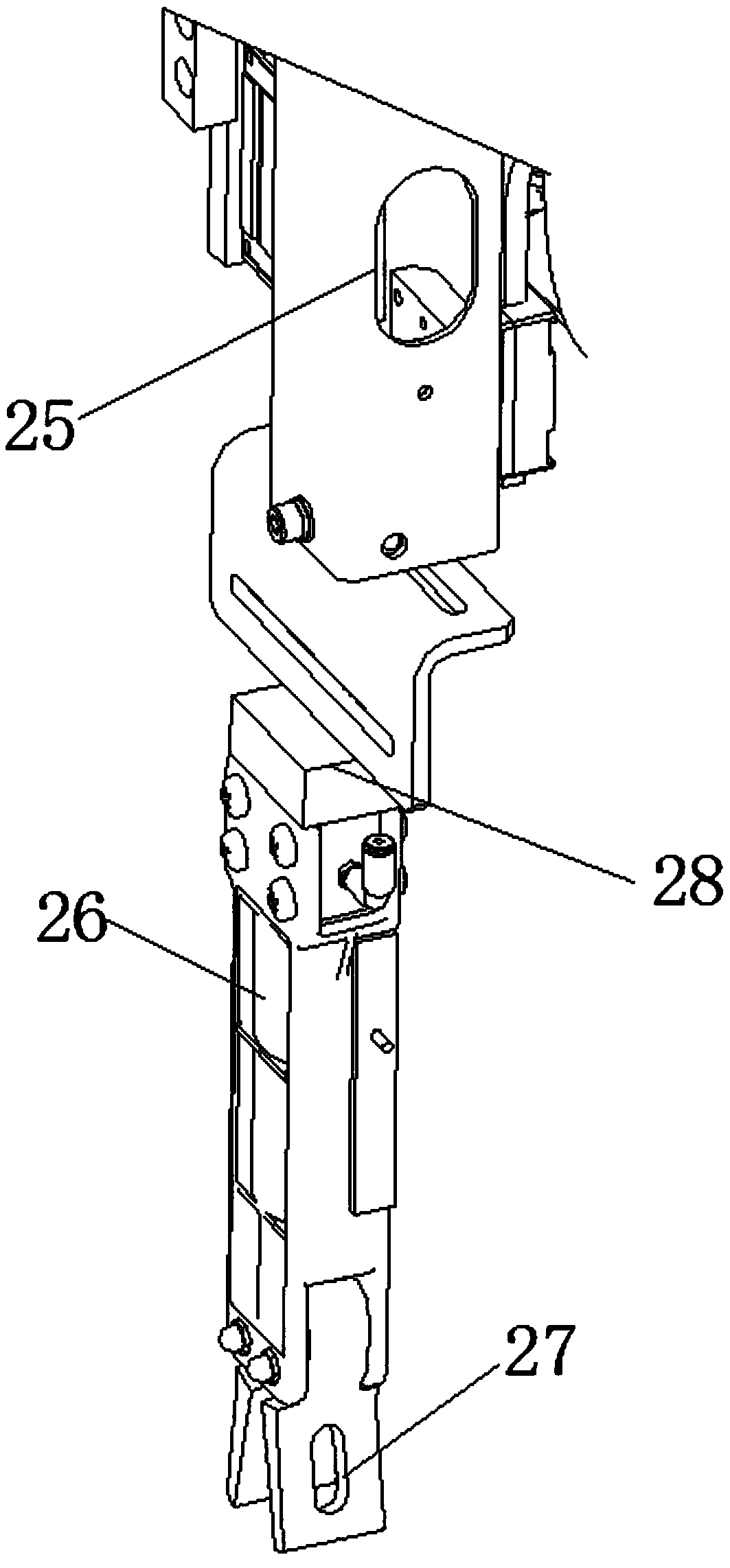

Injection molding robot with visual mold monitor

The invention relates to visual detection equipment, in particular to an injection molding robot with a visual mold monitor. The injection molding robot with the visual mold monitor can completely eliminate the serious visual distortion and blind areas of detection and protection of a traditional mold monitor, and has the characteristics of having high detection accuracy, being small and flexible,being capable of moving arbitrarily with a coordinate robot and integrating a mold monitoring protector and product quality visual inspection. The visual monitor is directly arranged on the coordinate robot. After the injection molding machine is opened, the coordinate robot descends to the interior of the mold with the monitor, can move arbitrarily and repeatedly according to detection key partsand takes photos continuously without dead angles or visual distortion; and after the shooting distance is shortened, the image definition generally increases by more than 200%, so that whether residues exist in a product and whether the product is taken out completely can be detected, whether metal and other plug-in components or pins inserted into the mold are installed in place can also be detected, whether the shaped product has quality defects such as incomplete filling, shrinkage, black spots and different colors is detected, the visual distortion is eliminated, the photos taken are clear and complete, and meanwhile the type of visual cameras is not limited.

Owner:SUZHOU IND PARK CHAOQUN AUTOMATION EQUIP

Metamorphopsia testing and related methods

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Digital multi-dimensional image photon platform system and methods of use

ActiveUS20180288241A1Quality improvementOvercome problemsOptical articlesStereoscopic photographyOutput deviceMulti dimensional

A systematic approach to producing multi-dimensional photon images on a computer platform having applications to a plurality of input image(s) from various sources, and applications to coordinate and adjust numerous variables which determine the quality of the image, such as the size of the imported images, the output image size, the resolving power of the viewing screen and the width of the resolving elements, the dots per inch of the output device (or pixels per inch), the desired nearest object, the desired furthest object and the determination of the central or the “key subject”, rules of interphasing, the number of frames or layers, the minimum parallax, and the maximum parallax, and, thus, provide a digital multi-dimensional image without jumping images or fuzzy features or other visual distortions by creating high quality output images both in the form of a printed hardcopy or as a viewed image on an appropriate viewing device. The digital multi-dimensional image platform based system controls the position and path of light from the original object to the human visual system.

Owner:NIMS JERRY +2

Digital multi-dimensional image photon platform system and methods of use

ActiveUS9992473B2Quality improvementOvercome problemsAdditive manufacturing apparatusPattern printingParallaxOutput device

A systematic approach to producing multi-dimensional photon images on a computer platform having applications to input image(s) from various sources, and applications to coordinate and adjust numerous variables which determine the quality of the image, such as the size of the imported images, the output image size, the resolving power of the viewing screen and the width of the resolving elements, the dots per inch of the output device (or pixels per inch), the desired nearest object, the desired furthest object and the determination of the central or the “key subject”, rules of interphasing, the number of frames or layers, the minimum parallax, and the maximum parallax, and, thus, provide a digital multi-dimensional image without jumping images or fuzzy features or other visual distortions by creating high quality output images both in the form of a printed hardcopy or as a viewed image on an appropriate viewing device.

Owner:NIMS JERRY +2

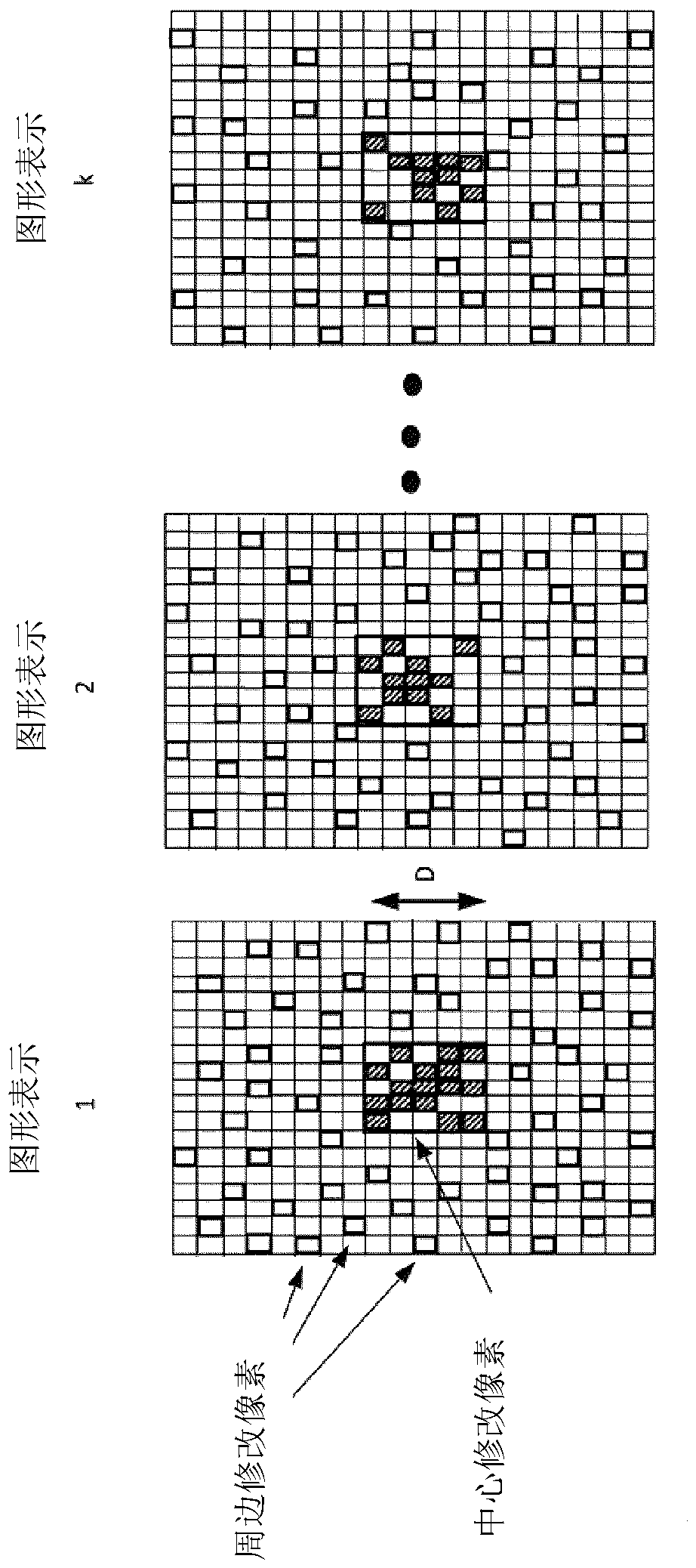

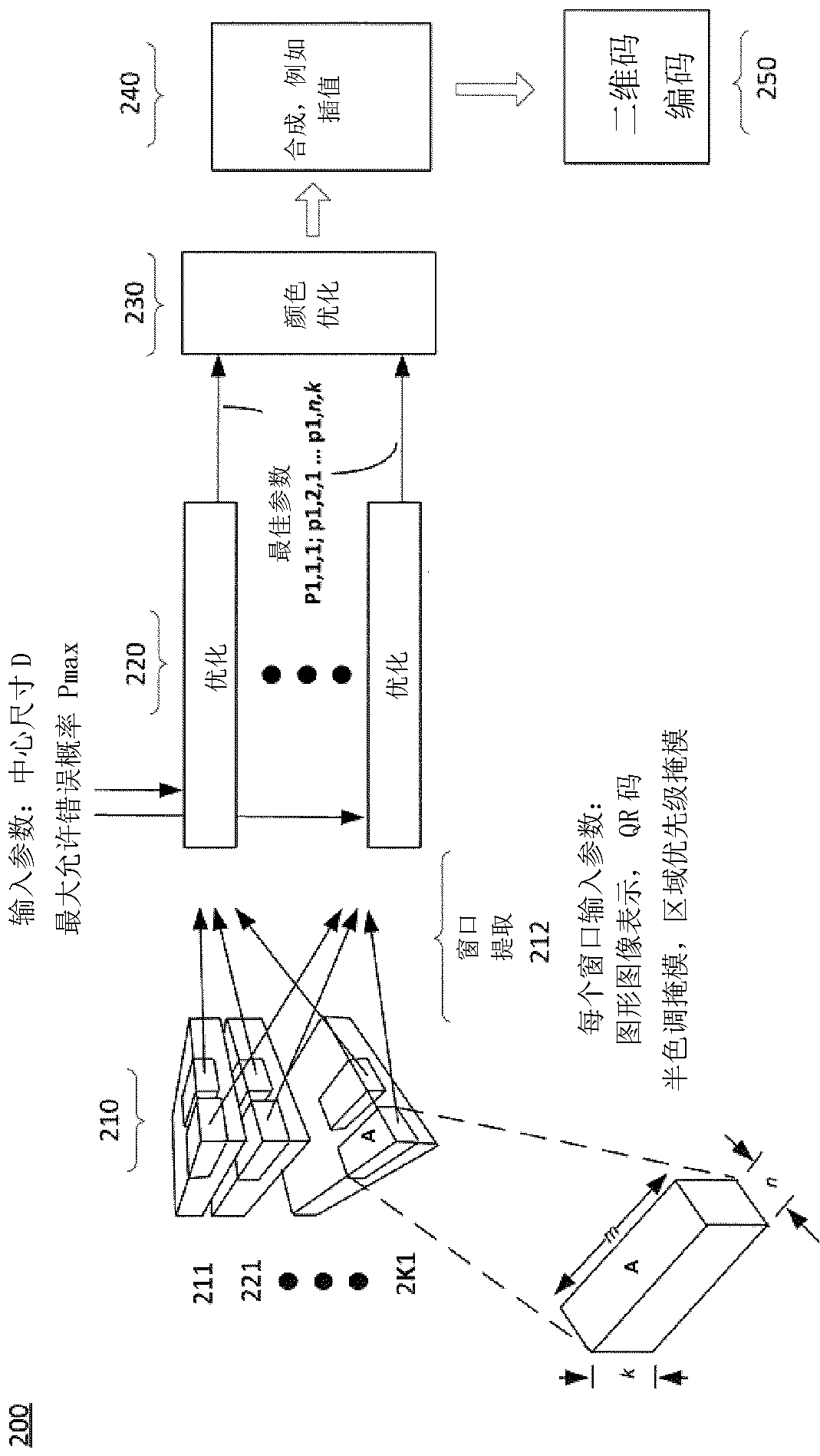

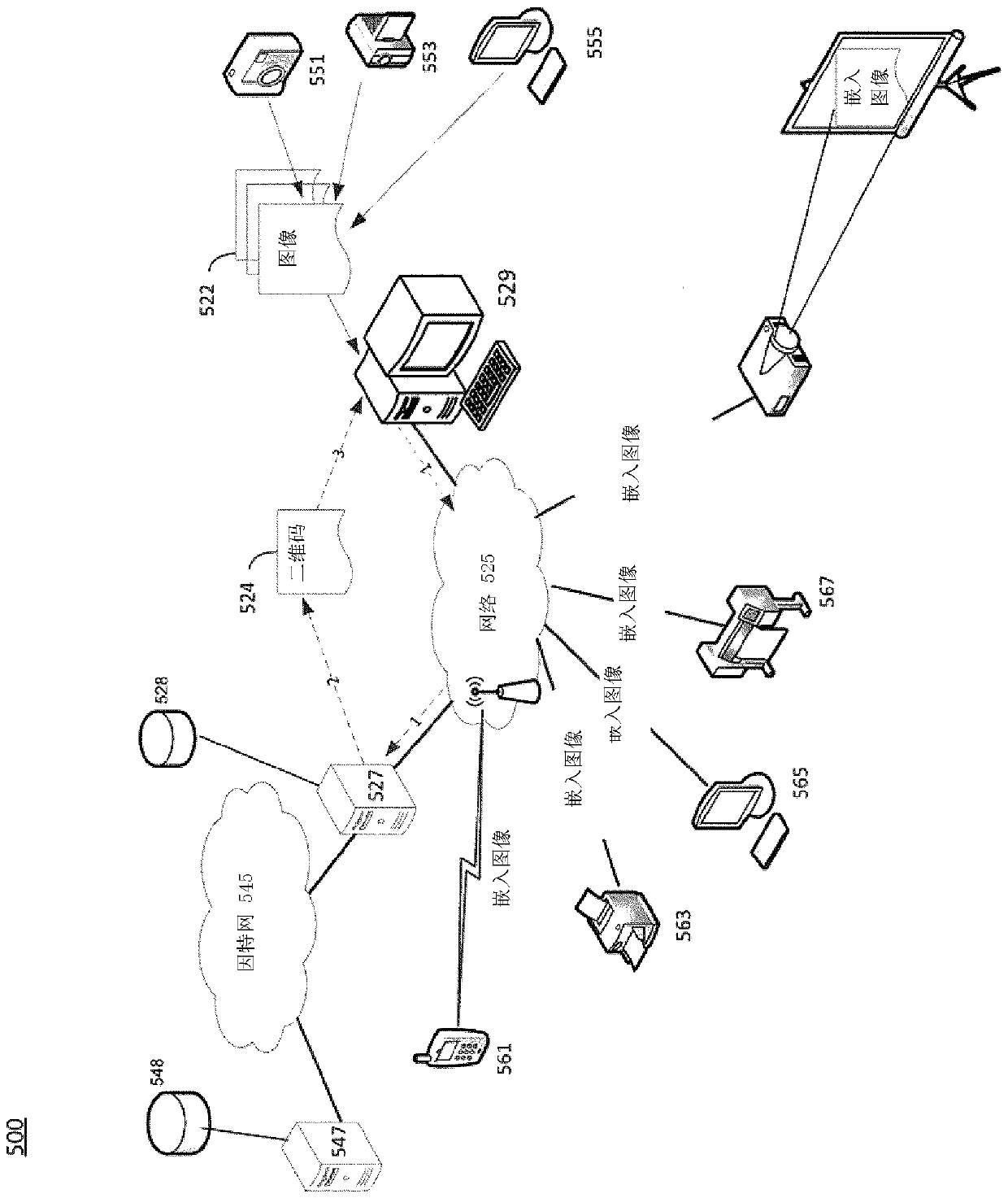

System and method for embedding a two dimensional code in video images

ActiveCN108064395AImage data processing detailsRecord carriers used with machinesProbit modelVideo image

Disclosed are a method and apparatus for embedding a graphic representation into a two dimensional matrix code by modifying the luminance of individual pixels in the image according the values of a provided QR code image. The modified luminance values are determined by means of an optimization procedure which minimizes a visual distortion metric with respect to the original graphic representationwhile maintaining the value of a model for the probability of decoding and detection error below a specified limit.

Owner:GRAPHICLEAD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com