3D-printing cervical vertebra side block screw guide embedded plate and manufacturing method thereof

A 3D printing and guide plate technology, which is applied in medical science, surgery, fixers, etc., can solve the problems of not being able to guide the lateral mass screw into the screw, and not being able to guide multiple cervical vertebral lateral masses, so as to ensure accuracy and reduce the difficulty of fitting , Simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

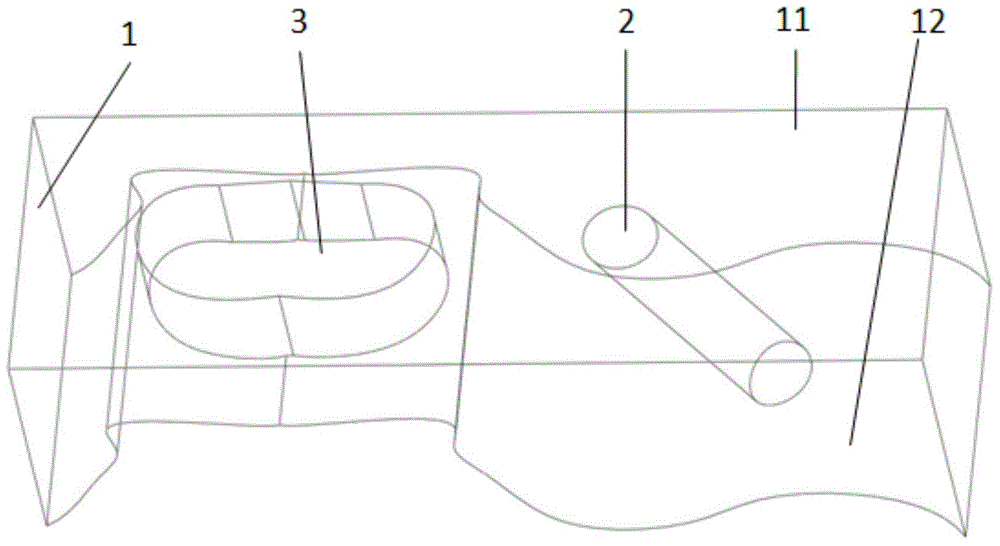

[0043] Example 1 3D printed cervical lateral mass screw-guided implant plate structure

[0044]A 3D printed cervical lateral mass screw-guided implant plate, including a solid guide plate 1, the size of which can cover a cervical lateral mass; There is also a spinous process hole 3; the spinous process hole 3 is located on the side of the guide plate 1, and the guide nail track 2 is set beside the spinous process hole 3. Track 2, the screw can accurately enter the lateral mass. The upper part of the guide plate 1 is a flat surface 11, and the curved surface 12 at the bottom of the guide plate 1 is consistent with the opposite direction of the surgical lamina; one side of the bottom curved surface 12 of the guide plate 1 extends to the outside of the side mass, and one side extends to the other side of the spinous process, and the curved surface of the bottom of the guide plate is vertically thickened to The upper plane of the guide plate. The shape of the spinous process hol...

Embodiment 2

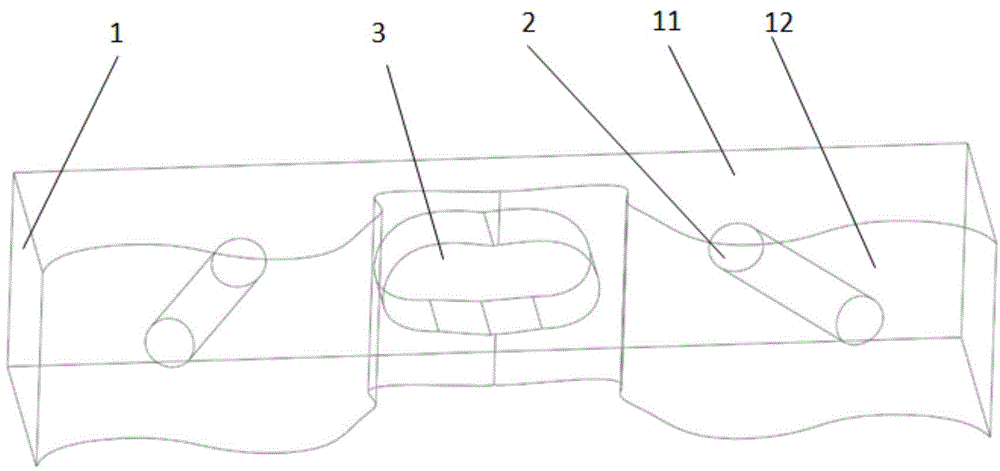

[0046] Example 2 3D printed cervical lateral mass screw-guided implant plate structure

[0047] A 3D-printed cervical lateral mass screw-guided implant plate, including a solid guide plate 1, the size of which can cover a cervical lateral mass; There is also a spinous process hole 3; the spinous process hole 3 is located in the center of the guide plate 1, and two guide nail tracks 2 are arranged on both sides of the spinous process hole 3, and the direction of the guide screw track 2 is consistent with the direction of the lateral mass screw screw entry track. Guide screw channel 2, the screw can accurately enter the lateral mass. The upper part of the guide plate 1 is a plane 11, and the bottom curved surface 12 of the guide plate 1 can be consistent with the operation lamina; the bottom curved surface 12 of the guide plate 1 extends to the outside of the side blocks on both sides, and the bottom curved surface of the guide plate is vertically thickened to the upper plane of...

Embodiment 3

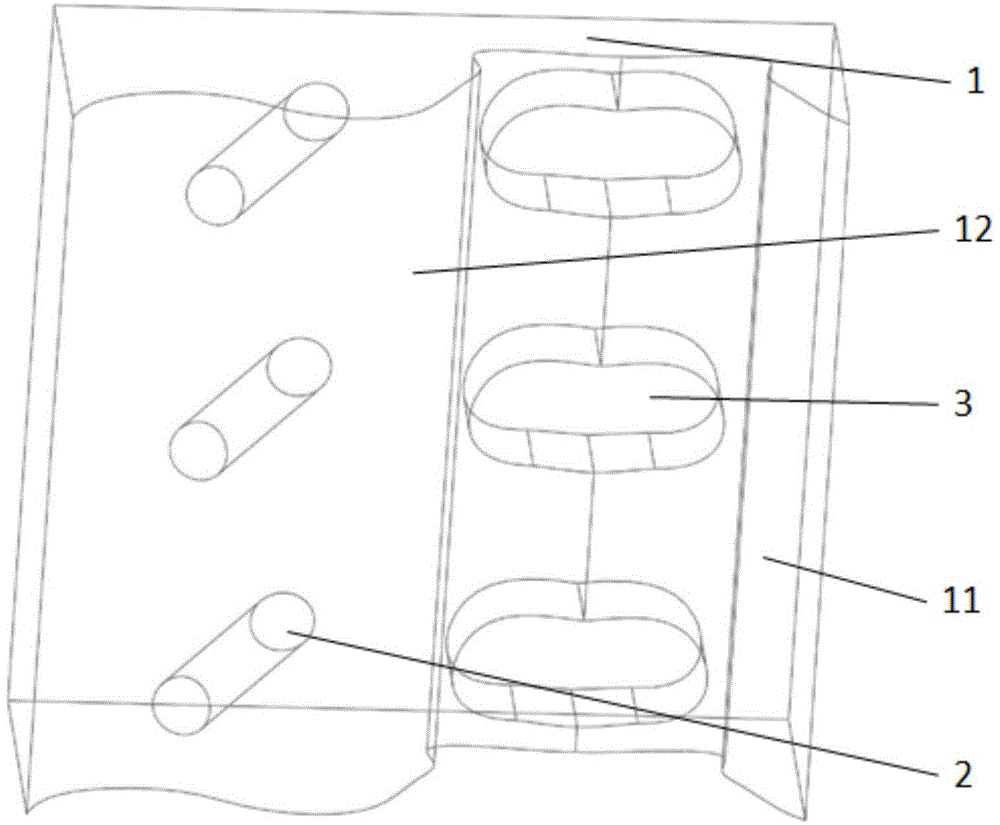

[0049] Example 3 3D printed cervical lateral mass screw-guided implant plate structure

[0050] A 3D-printed cervical lateral mass screw-guided implant plate, including a solid guide plate 1, the size of which can cover three cervical vertebral lateral masses; There are also three spinous process holes 3; the spinous process holes 3 are located on one side of the guide plate 1, and the guide nail track 2 is set on the other side of the guide plate 1. Screw channel 2, the screw can accurately enter the lateral mass. The upper part of the guide plate 1 is a flat surface 11, and the curved surface 12 at the bottom of the guide plate 1 is consistent with the opposite direction of the surgical lamina; one side of the bottom curved surface 12 of the guide plate 1 extends to the outside of the side mass, and one side extends to the other side of the spinous process, and the curved surface of the bottom of the guide plate is vertically thickened to The upper plane of the guide plate....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com