Three-dimensional luminous LED device and manufacturing method thereof

A LED device and three-dimensional technology, applied in the field of three-dimensional light-emitting LED devices and their production, can solve the problems of high welding precision requirements, unstable electrical connections, and low chip life, so as to improve heat dissipation performance and improve product production efficiency. The effect of high rate and product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

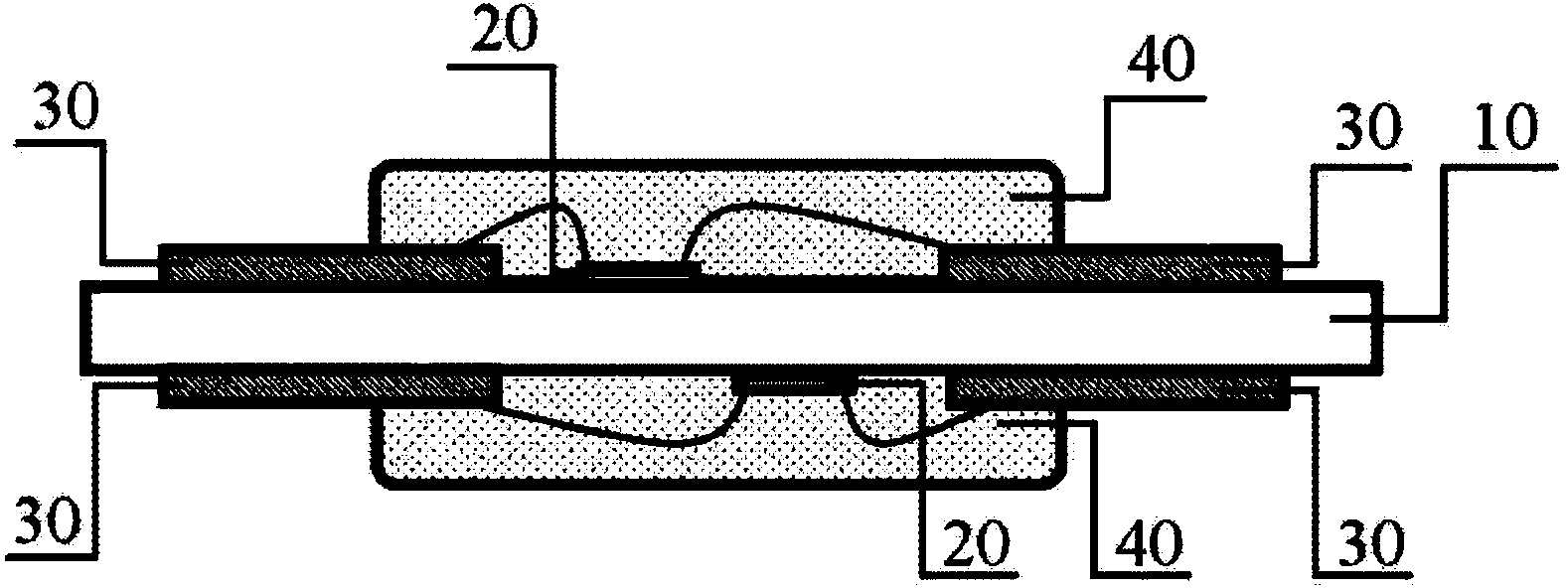

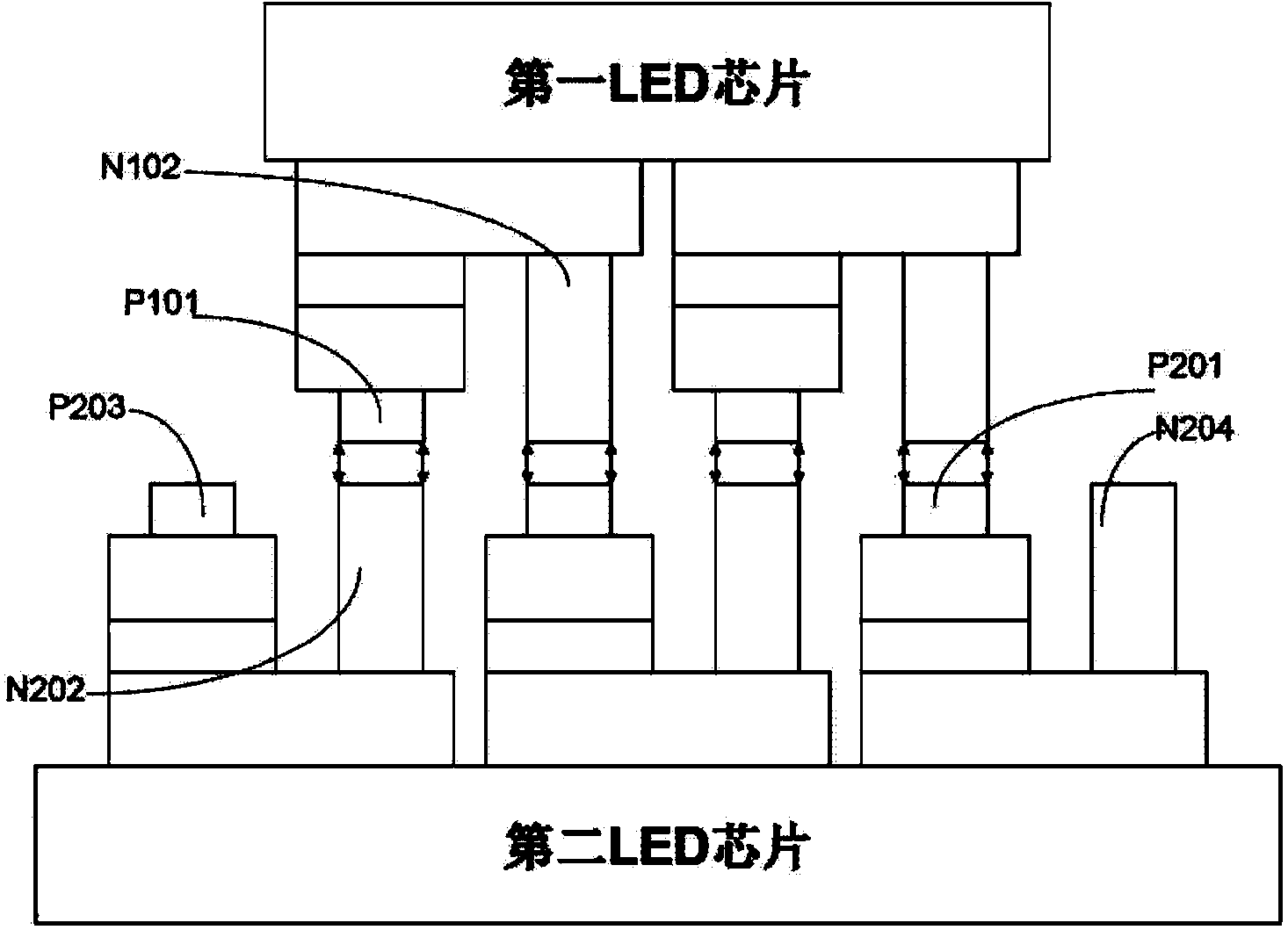

[0044] Figure 4 It is a structural schematic diagram of the LED device of the present invention, such as Figure 4 As shown, this embodiment discloses a three-dimensional light-emitting LED device, including a first direct-mount LED chip 100 (the LED chip located on the electrode lead-out metal sheet 300 in the figure) and a second direct-mount LED chip 100 that are oppositely arranged. Mounted LED chip 100 (the LED chip located under the electrode lead-out metal sheet 300 in the figure), the N electrode bonding layer of the first direct mount LED chip and the N electrode of the second direct mount LED chip There is an electrode lead-out metal sheet 300 electrically connected between the bonding layers (since its function is to lead out the N electrode of the LED, it can also be called the N electrode lead-out metal sheet), and the P electrode bond of the first direct mount LED chip There is an electrode lead-out metal sheet 300 electrically connected between the bonded laye...

Embodiment 2

[0058] like Figure 5 As shown, the difference between this embodiment and Embodiment 1 lies in that the shape of the light-converting substance material layer 200 is different.

[0059] In this embodiment, during the manufacturing process of the light conversion substance material layer 200, the three-dimensional light-emitting device manufactured by using a specially designed mold top mold has a light-emitting form of an LED light-emitting sphere, which realizes 360° full-angle light emission.

Embodiment 3

[0061] The only difference in this embodiment is that the manufacturing method of the three-dimensional light-emitting LED device is slightly different:

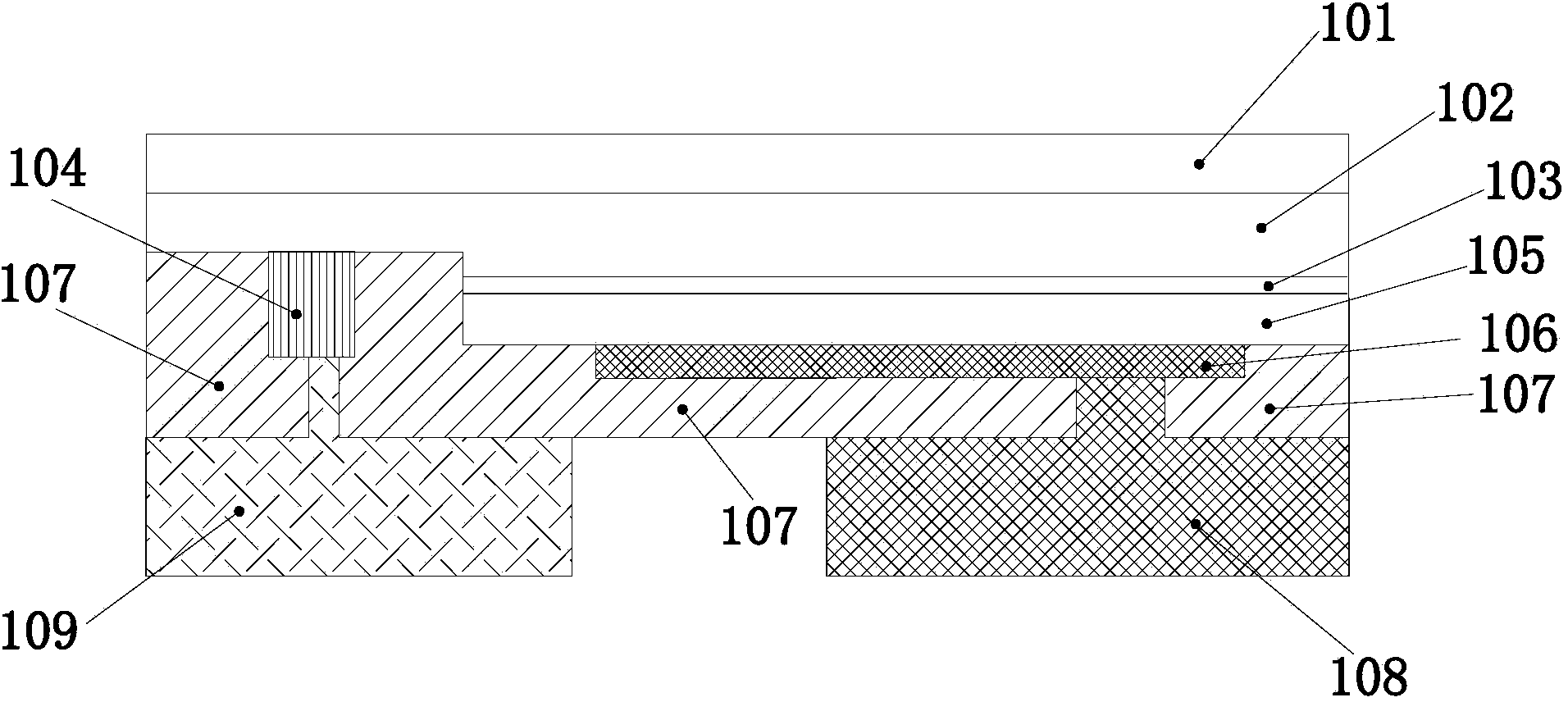

[0062] like Image 6 As shown, in this embodiment, after the direct mount LED chip 100 is fabricated, the light-converting material layer 200 is fabricated on its outer surface, and then bonded to the electrode lead-out metal sheet 300 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com