Cover plate and preparation method and laminating method thereof

A cover plate and glass plate technology, applied in branch equipment, telephone structure, telephone communication, etc., can solve the problems of low lamination efficiency of cover plates, and achieve the effect of reducing lamination difficulty and improving lamination efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

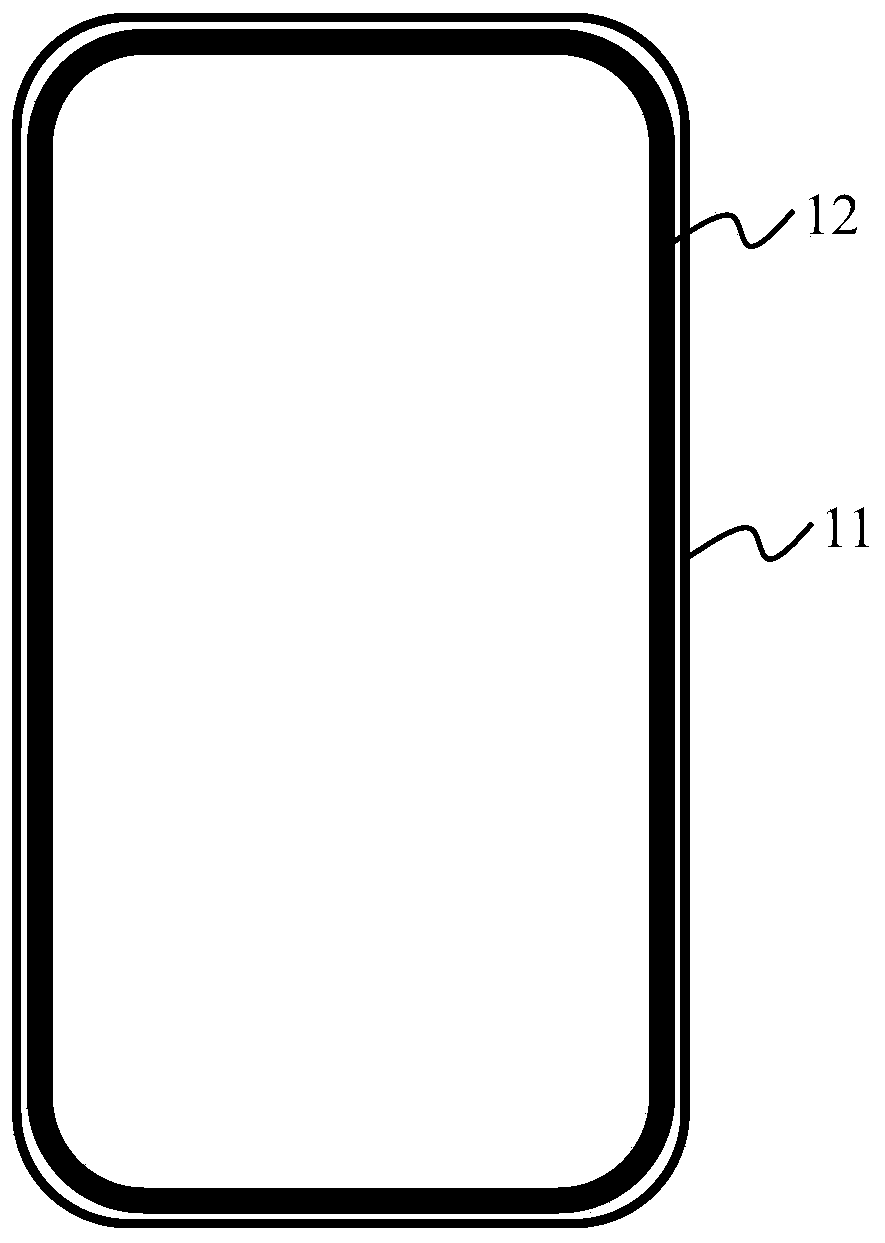

[0032] see figure 1 As shown, the embodiment of the present application discloses a cover plate, and the cover plate includes a flexible glass plate 11 and a memory alloy frame 12 . The memory alloy frame 12 is located in the flexible glass plate. The memory alloy frame 12 includes an initial state and a deformed state. The memory alloy frame in the initial state drives the flexible glass plate to remain in a curved shape, and the memory alloy frame in the deformed state Drive the flexible glass plate to keep it in a flat shape.

[0033] In the embodiment of the present invention, the memory alloy frame includes two states (initial state and deformation state). The state thus drives the shape of the flexible glass plate to become a curved surface. The memory alloy frame can be a rectangular frame or a "day" shape. The present invention does not limit its specific shape, as long as it can drive the shape of the flexible glass plate into a curved shape.

[0034] It is pointed...

Embodiment 2

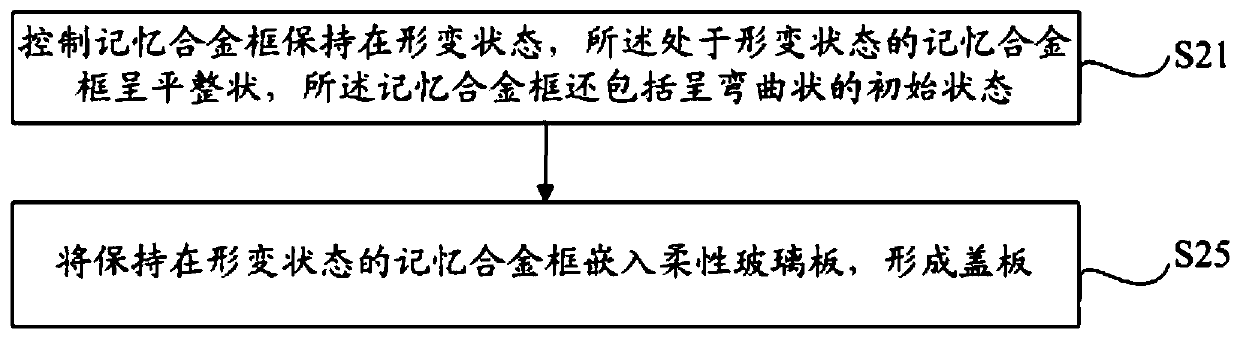

[0052] Based on the cover described in the above embodiments, the embodiment of the present application provides a preparation method for the above cover, which may specifically include the following steps:

[0053] Step S21, controlling the memory alloy frame to remain in a deformed state, the memory alloy frame in the deformed state is flat, and the memory alloy frame also includes a curved initial state;

[0054] In the embodiment of the present application, the memory alloy frame is controlled to remain in a deformed state, the memory alloy frame in the deformed state is flat, and the memory alloy frame also includes an initial state in a curved shape.

[0055] Specifically, in the embodiment of the present application, by heating the memory alloy frame, such as heating to 38-42 degrees Celsius, such as 38 degrees Celsius, 40 degrees Celsius or 42 degrees Celsius; after that, performing cooling mechanical treatment on the memory alloy frame, Cool the memory alloy frame to ...

Embodiment 3

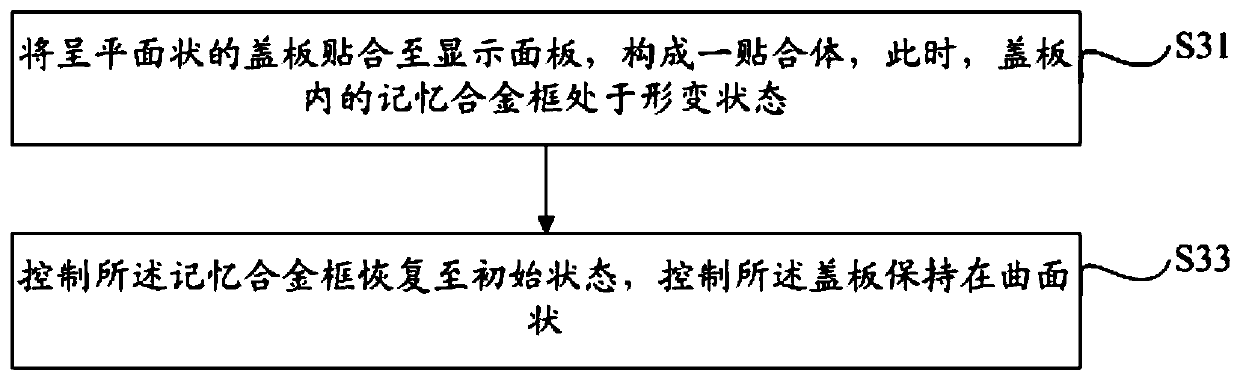

[0071] Based on the cover plate and the preparation method of the cover plate described in the above-mentioned embodiments, the embodiment of the present application provides a bonding method for bonding the above-mentioned cover plate or the cover plate prepared by the above-mentioned preparation method to the light-emitting device, see image 3 As shown, the bonding method disclosed in the embodiment of the present application includes:

[0072] Step S31, attaching the planar cover plate to the display panel, at this time, the memory alloy frame in the cover plate is in a deformed state;

[0073] In the embodiment of this application, the planar cover plate is bonded to the display panel to form a Figure 4 As shown in the schematic diagram of the structure, specifically, the bonding position can be:

[0074] The center of the planar cover overlaps with the center of the display panel, so that the display panel can be effectively attached to the central area of the flexib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com