Flexible cover plate, production method of flexible cover plate and flexible OLED display device

A manufacturing method and flexible cover technology, which are applied in identification devices, semiconductor/solid-state device manufacturing, instruments, etc., can solve problems such as unfavorable bending of flexible OLED display devices, increase in thickness, etc., so as to facilitate production yield, reduce thickness, and improve The effect of bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

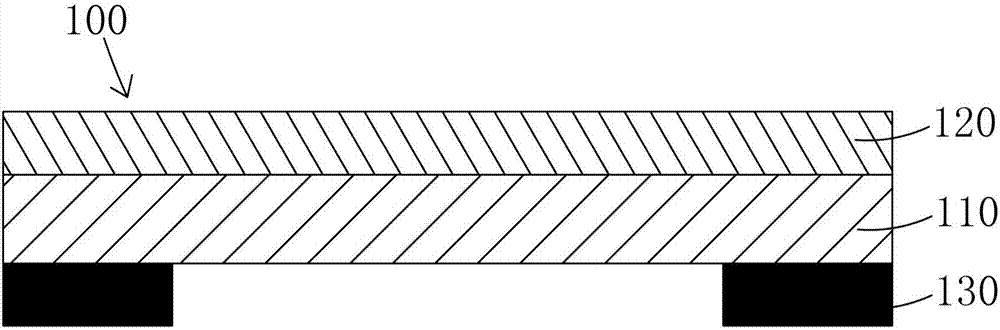

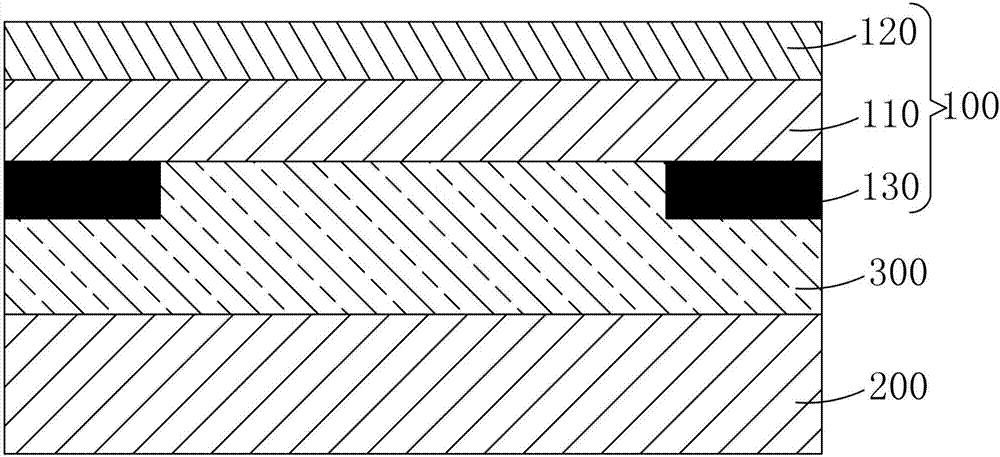

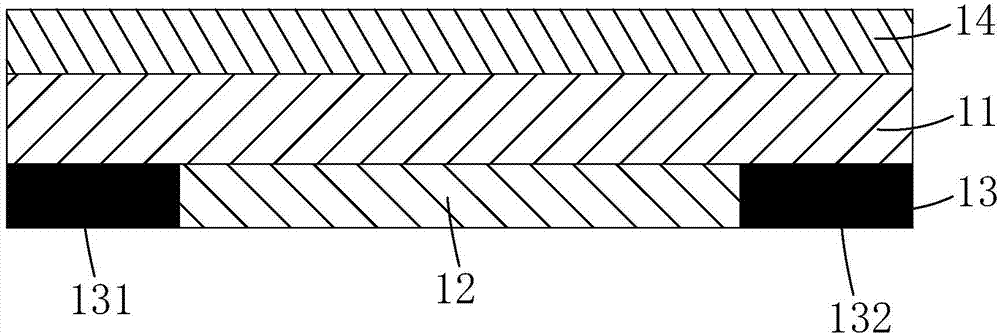

[0049] Based on the flexible cover above, see Figure 5 , the present invention also provides a method for manufacturing a flexible cover, the first embodiment of the method for manufacturing a flexible cover of the present invention specifically includes the following steps:

[0050] Step S1 , making the first flexible substrate 11 .

[0051] Specifically, the thickness of the first flexible substrate 11 depends on requirements, and may be selected to be 20-50 μm.

[0052] Specifically, the material of the first flexible substrate 11 is a bending-resistant material, such as polyethylene terephthalate, polyimide and other materials. Further, the material of the first flexible substrate 11 Polyimide material is preferred.

[0053] Step S2, forming a second flexible substrate 12 and an ink layer 13 on one side of the first flexible substrate 11, and forming a hardened layer 14 on the other side of the first flexible substrate 11; wherein, the ink layer 13 includes The first i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com