Chlorinated-water-resistant inflatable swimming pool material

A swimming pool, chlorine-resistant technology, applied in the direction of layered products, synthetic resin layered products, chemical instruments and methods, etc., can solve the physical properties of fading, oxidation yellowing, impact resistance, tear resistance, etc. The aging resistance is not satisfactory, etc. problems, achieve the effect of improving softness, preventing oxidation and improving sizing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

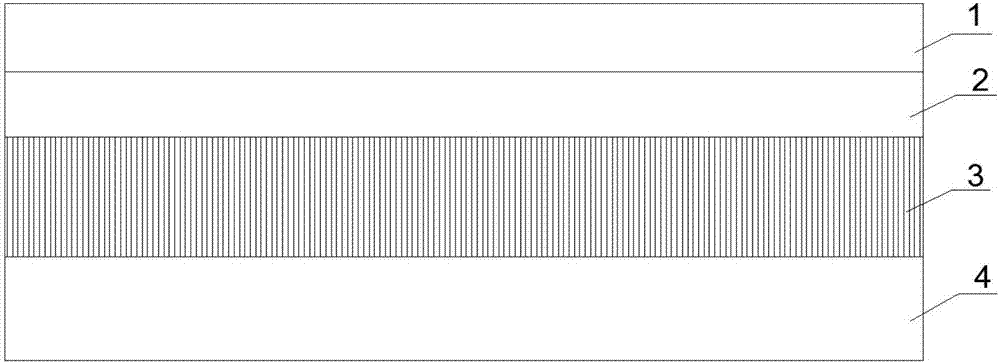

[0025] refer to figure 1 , a chlorine-resistant water inflatable swimming pool material, the inflatable swimming pool material comprises a PVC printing film 1, a PVC airtight film 2, a base cloth 3, a PVC bottom film 4 from top to bottom, and the PVC printing film is made of a transparent PVC film Made of single-sided printing ink; the inflatable swimming pool material is prepared through the following steps: After the base fabric is double-sided synchronously sized, it is dried and heated, and the preheated PVC printed film, PVC airtight film, and PVC bottom film Carry out synchronous lamination, and then roll up after trimming;

[0026] Wherein, the raw materials of the transparent PVC film are: 100 parts by weight of PVC resin powder with a degree of polymerization of 1300, 58 parts by weight of DOTP plasticizer, 2 parts by weight of soybean oil, and 3 parts by weight of Ba-Zn stabilizer;

[0027] The raw materials of the PVC airtight film are: 100 parts by weight of PVC r...

Embodiment 2

[0040] refer to figure 1 , a chlorine-resistant water inflatable swimming pool material, the inflatable swimming pool material comprises a PVC printing film 1, a PVC airtight film 2, a base cloth 3, a PVC bottom film 4 from top to bottom, and the PVC printing film is made of a transparent PVC film Made of single-sided printing ink; the inflatable swimming pool material is prepared through the following steps: After the base fabric is double-sided synchronously sized, it is dried and heated, and the preheated PVC printed film, PVC airtight film, and PVC bottom film Carry out synchronous lamination, and then roll up after trimming;

[0041] Wherein, the raw materials of the transparent PVC film are: 100 parts by weight of PVC resin powder with a degree of polymerization of 1300, 50 parts by weight of DOTP plasticizer, 1 part by weight of soybean oil, and 2 parts by weight of Ba-Zn stabilizer;

[0042] The raw materials of the PVC airtight film are: 100 parts by weight of PVC resi...

Embodiment 3

[0051] refer to figure 1 , a chlorine-resistant water inflatable swimming pool material, the inflatable swimming pool material comprises a PVC printing film 1, a PVC airtight film 2, a base cloth 3, a PVC bottom film 4 from top to bottom, and the PVC printing film is made of a transparent PVC film Made of single-sided printing ink; the inflatable swimming pool material is prepared through the following steps: After the base fabric is double-sided synchronously sized, it is dried and heated, and the preheated PVC printed film, PVC airtight film, and PVC bottom film Carry out synchronous lamination, and then roll up after trimming;

[0052] Wherein, the raw materials of the transparent PVC film are: 100 parts by weight of PVC resin powder with a degree of polymerization of 1300, 65 parts by weight of DOTP plasticizer, 5 parts by weight of soybean oil, and 5 parts by weight of Ba-Zn stabilizer;

[0053] The raw materials of the PVC airtight film are: 100 parts by weight of PVC r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com