Free-form surface adaptive machining track planning method

A processing trajectory, self-adaptive technology, applied in the direction of instruments, digital control, control/regulation systems, etc., can solve the problems affecting processing efficiency and accuracy, difficult to obtain offset surfaces, difficult to minimize the amount of overlap, etc., to improve processing. Efficiency, shorten the length of the trajectory path, and achieve the effect of precise overlapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] specific implementation plan

[0027] The method of the present invention will be described in further detail below in conjunction with the accompanying drawings.

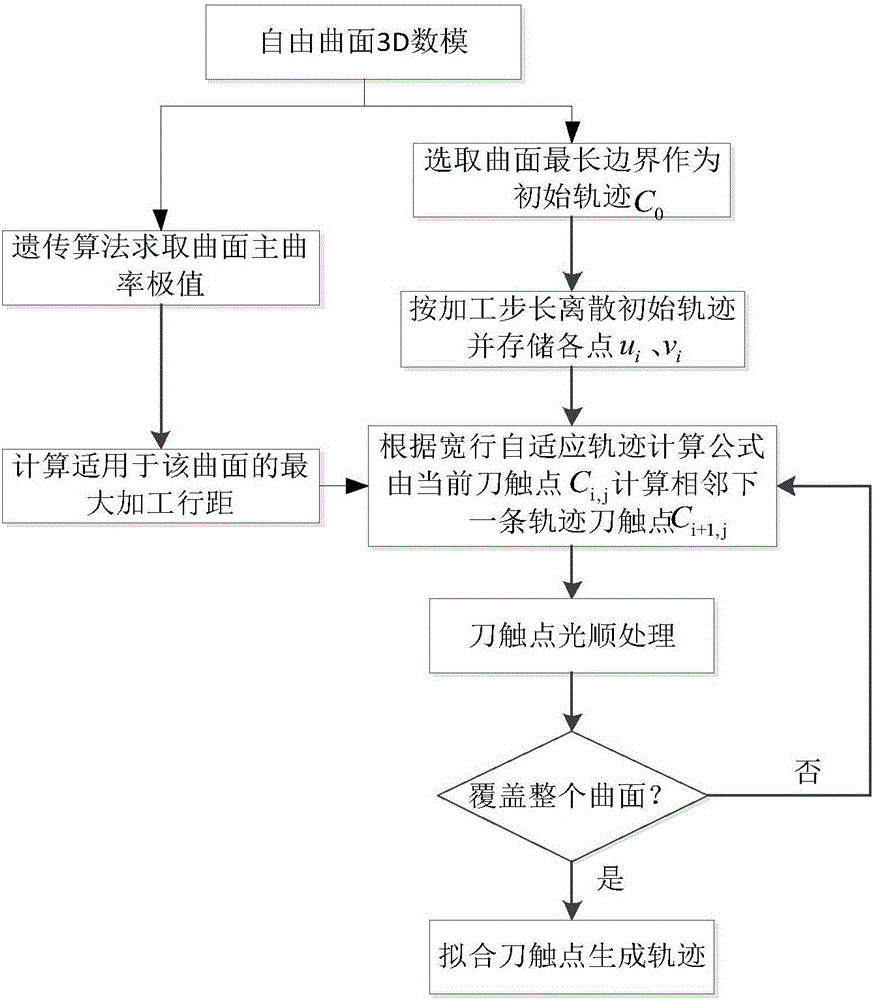

[0028] Such as figure 1 Shown, the inventive method comprises the following steps:

[0029] Step 1: Identify the surface features of the complex free-form surface, store the surface parameters u and v in the form of diploid genes, and use the u and v parameters to obtain the principal curvature of the point. The specific method is as follows:

[0030] Let the parametric equation of the free-form surface be S(u, v), then:

[0031] (EG-F 2 )k 2 N -(LG-2MF+NE)k N +(LN-M 2 )=0

[0032] According to the relationship between the root and the coefficient can be obtained:

[0033] k 1 · k 2 = L N - M 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com