Polypropylene melt index predicating method based on multiple priori knowledge mixed model

A technology based on prior knowledge and melt index, applied in the field of soft sensor prediction of polypropylene industrial process, can solve the problems of pure data-driven model extrapolation ability and safety performance cannot be guaranteed, and the accuracy of pure mechanism model is not high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The present invention will be further described below in conjunction with the accompanying drawings.

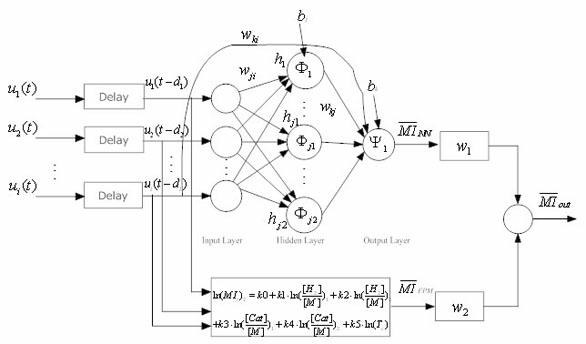

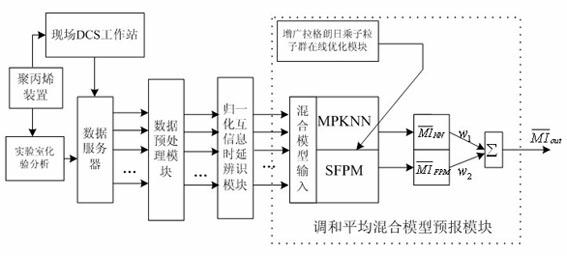

[0075] refer to figure 2 , image 3 , a polypropylene melt index prediction method based on multiple prior knowledge mixed models, the specific implementation method is as follows:

[0076] (1) Offline modeling

[0077] First off-line initialization to establish a polypropylene melt index prediction model based on multiple prior knowledge mixed models, the specific process is as follows:

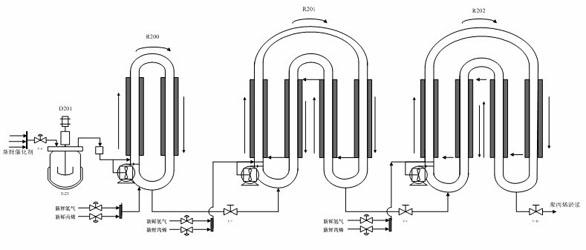

[0078] 1) From a loop-type liquid phase propylene bulk polymerization field device of a Chinese petrochemical company ( figure 1 ), collect the data needed to establish the soft sensor model through two ways. According to the production process and reaction mechanism of double-loop liquid phase propylene bulk polymerization, the auxiliary variable of the soft sensor model is determined to be the hydrogen concentration of the two loops , Hydrogen feed amount , Feed amoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com