Total-space smooth hole insertion control method applied to assembly robot and based on real-time force control

A control method and robot technology, applied in the direction of program control of manipulators, manipulators, manufacturing tools, etc., can solve the problems of judging and difficult to adapt to the needs of full-space operation of robots, so as to improve the success rate and efficiency, and avoid jamming and tightness. Phenomenon, Effect of Overcoming Hole-Shaft Alignment Error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

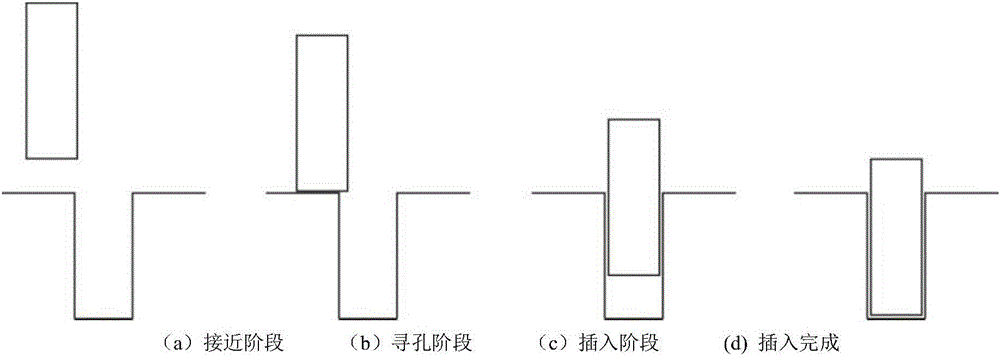

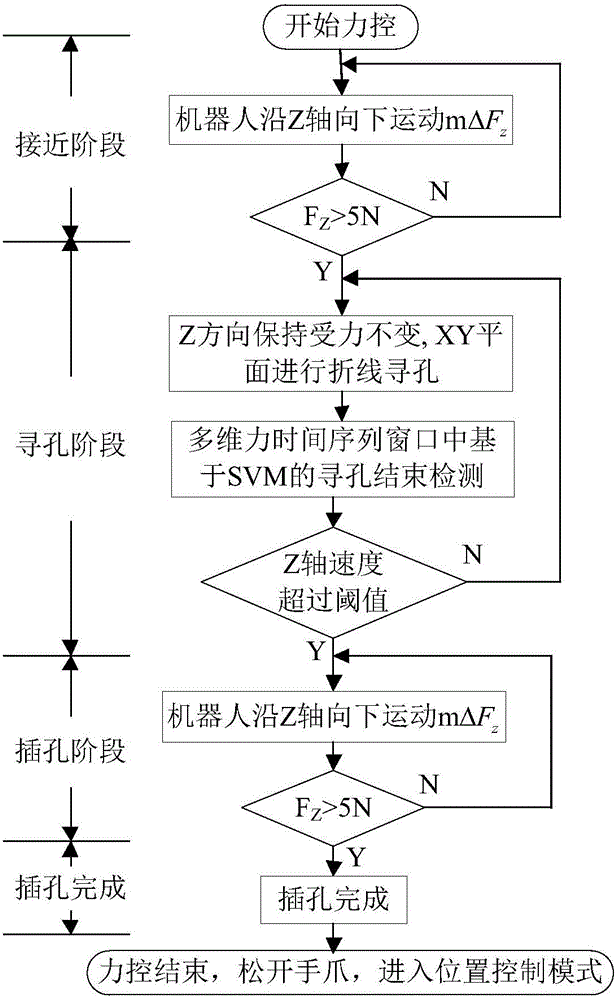

[0033] A full-space compliant socket control method for an assembly robot based on real-time force control, comprising the following steps:

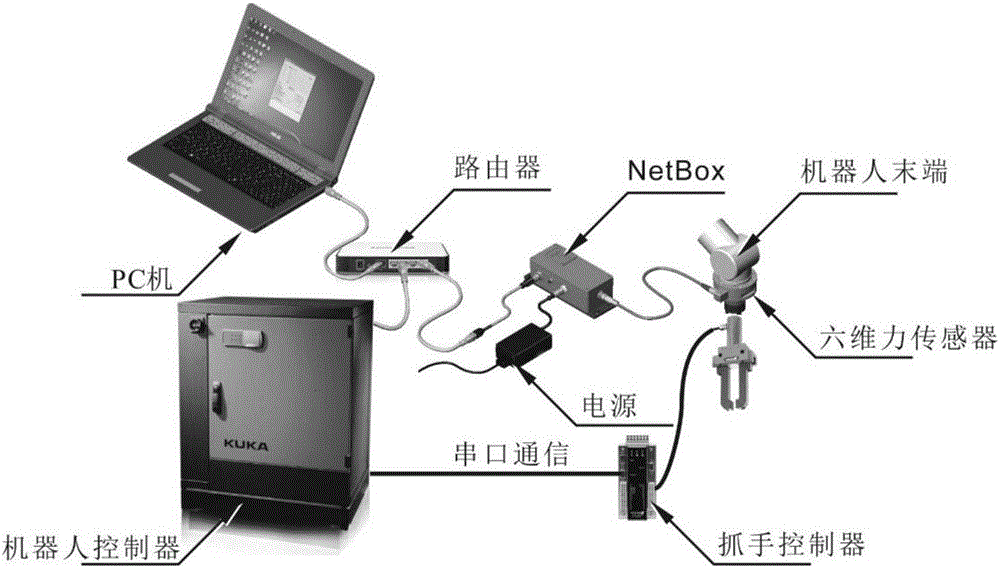

[0034] Step 1. Use the six-dimensional wrist force sensor, real-time communication software package, etc. to build a real-time communication force control platform for the assembly robot.

[0035] The specific steps are as follows: The system is mainly composed of KUKA robot body, robot controller and end effector, force sensor, upper computer and other main parts. The overall structure of the system is as figure 1 shown. The force sensor is installed at the end of the robot through an adapter to collect real-time force signals, and through the analysis of NetBox, the six-dimensional force data required for force control is obtained and sent to the host computer through Ethernet. The KUKA RSI real-time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com