Full-automatic alignment and assembly machine

An assembly machine, fully automatic technology, applied in the direction of manipulator, metal processing, metal processing equipment, etc., can solve the problems of non-concentric angle of LCD screen and watch case, increase labor intensity of workers, low work efficiency, etc., to achieve compact structure, structure Simple, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

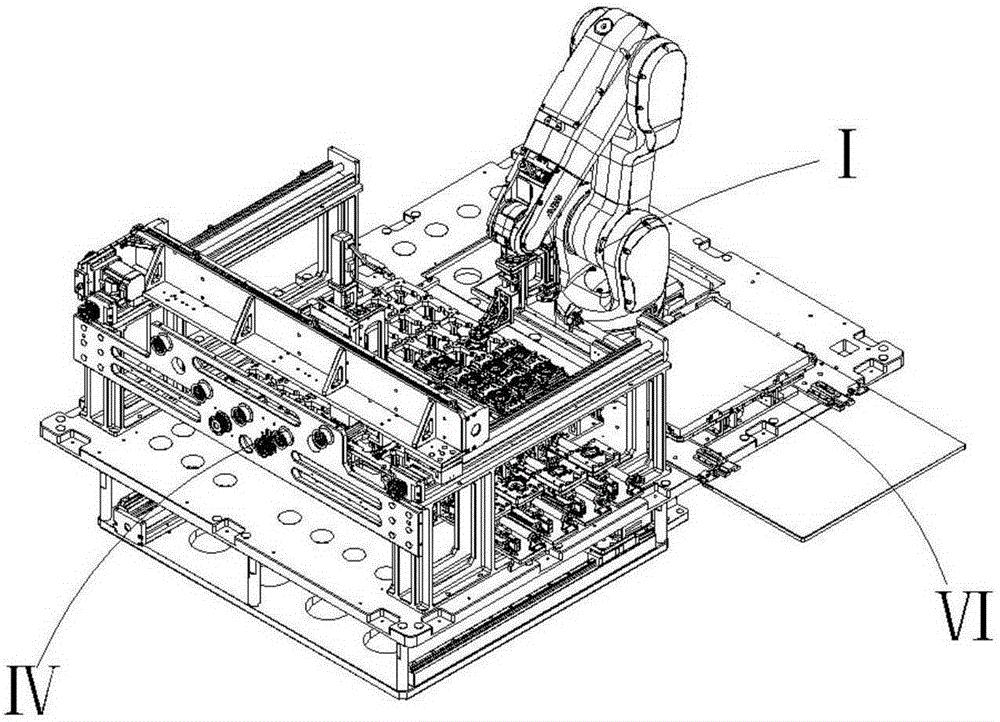

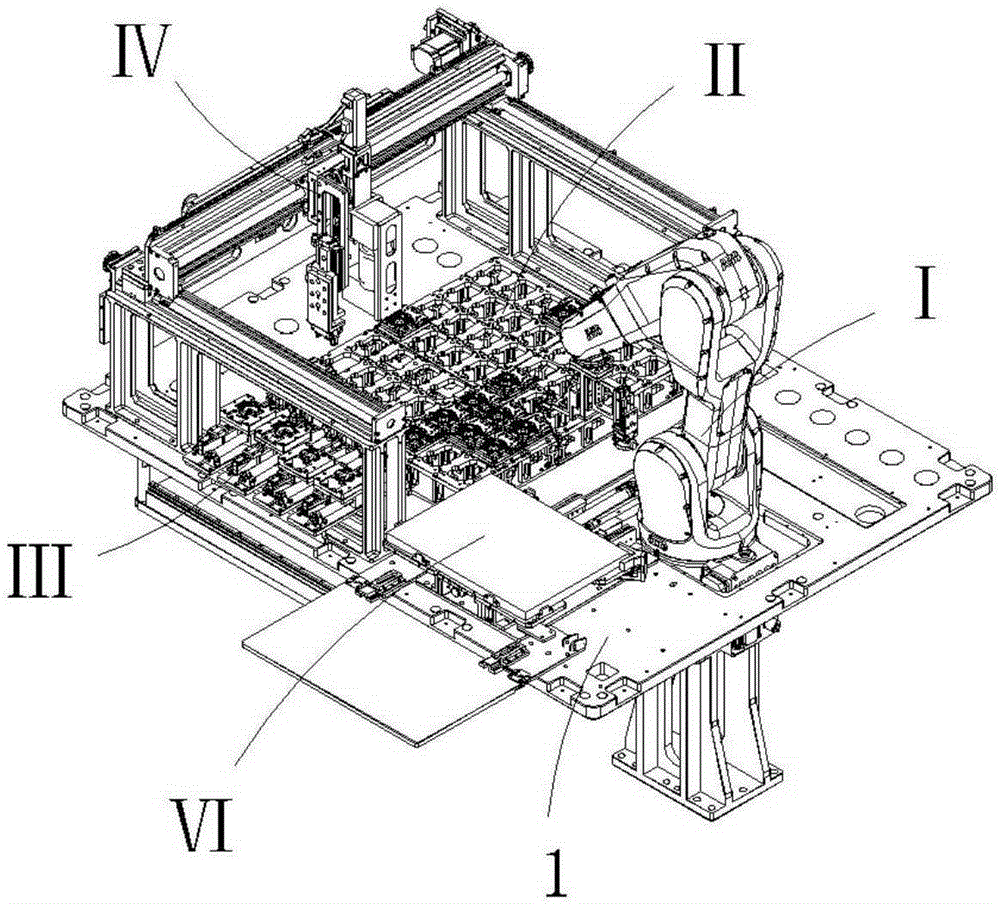

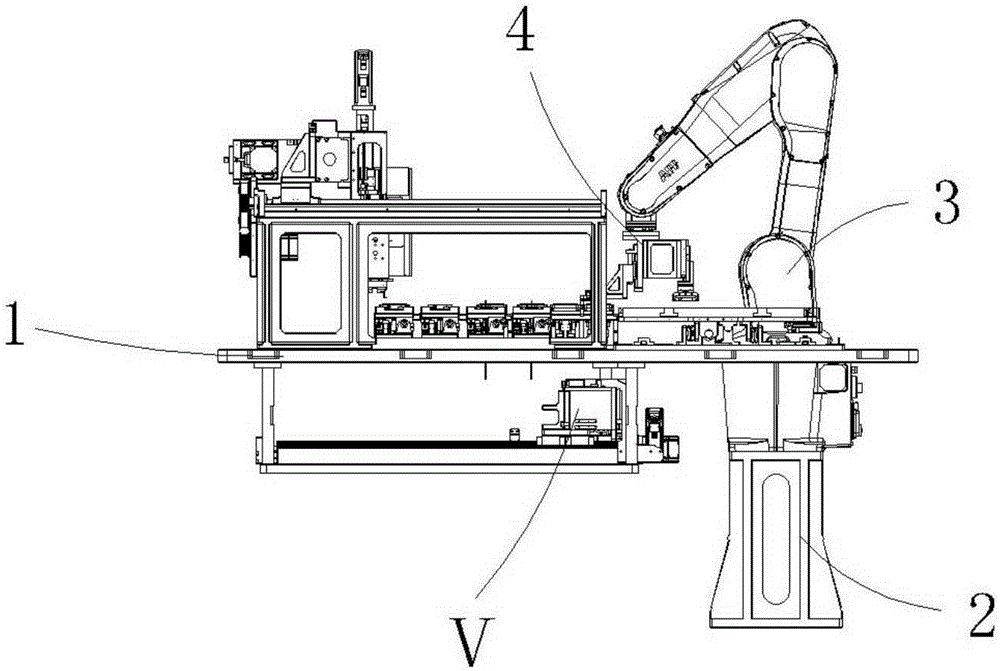

[0047] Examples, see attached Figure 1-21 , a fully automatic alignment assembly machine, which includes a base plate 1, a manipulator mechanism I and a carrier mechanism II, the manipulator mechanism is installed on the base plate, the carrier mechanism is installed on the base plate, and also includes a feeding mechanism III, a camera grab The taking mechanism IV, the jacking mechanism V and the finished product removing mechanism VI; the feeding mechanism, the photographing grabbing mechanism and the finished product removing mechanism are respectively installed on the bottom plate; the jacking mechanism is installed under the bottom plate.

[0048] The manipulator mechanism includes a manipulator base 2, a manipulator 3 and a manipulator suction cup jaw assembly 4, the manipulator base is installed below the base plate, the manipulator is installed on the manipulator base, and the manipulator suction cup jaw assembly is installed on the manipulator.

[0049] The carrier m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com