Backlight CCD laminating technology and backlight CCD laminator

A technology of backlight source and laminating machine, applied in lamination device, lamination auxiliary operation, lamination and other directions, can solve the problems of adsorption offset of the film to be attached, offset of the film to be attached, inaccurate position information, etc. Accurate and accurate information collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

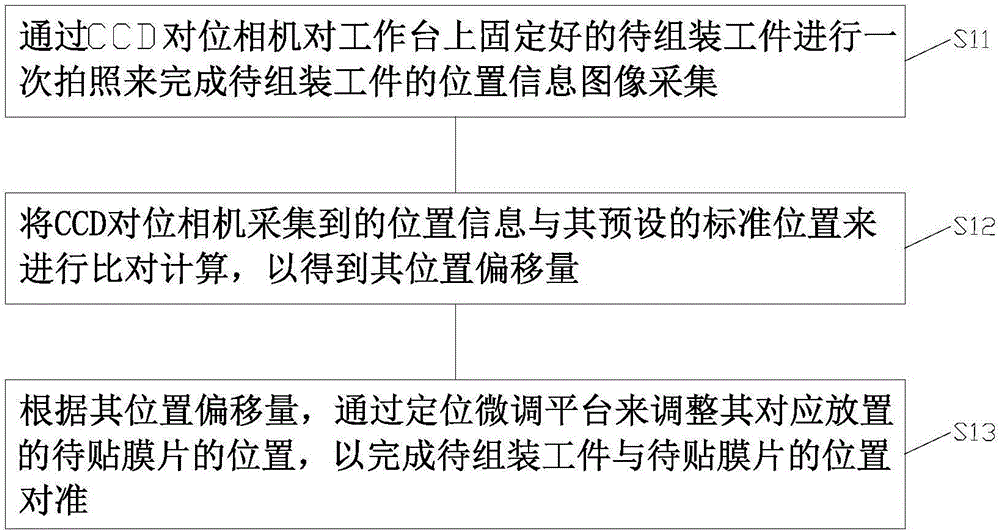

[0039] Embodiment one: if figure 1 As shown, the present embodiment provides a backlight CCD film sticking process, including a diaphragm discharging process, a diaphragm alignment process, and a diaphragm bonding process, wherein the diaphragm alignment process includes the following steps:

[0040] Step S11: take a photo of the workpiece to be assembled after preliminary positioning on the workbench through the CCD alignment camera to complete the image acquisition of the position information of the workpiece to be assembled;

[0041] Step S12: Comparing and calculating the position information collected by the CCD alignment camera with its preset standard position to obtain its position offset;

[0042] Step S13: According to the position offset, adjust the position of the corresponding film to be attached by positioning the fine-tuning platform, so as to complete the alignment between the workpiece to be assembled and the film to be attached.

[0043] In this embodiment, ...

Embodiment 2

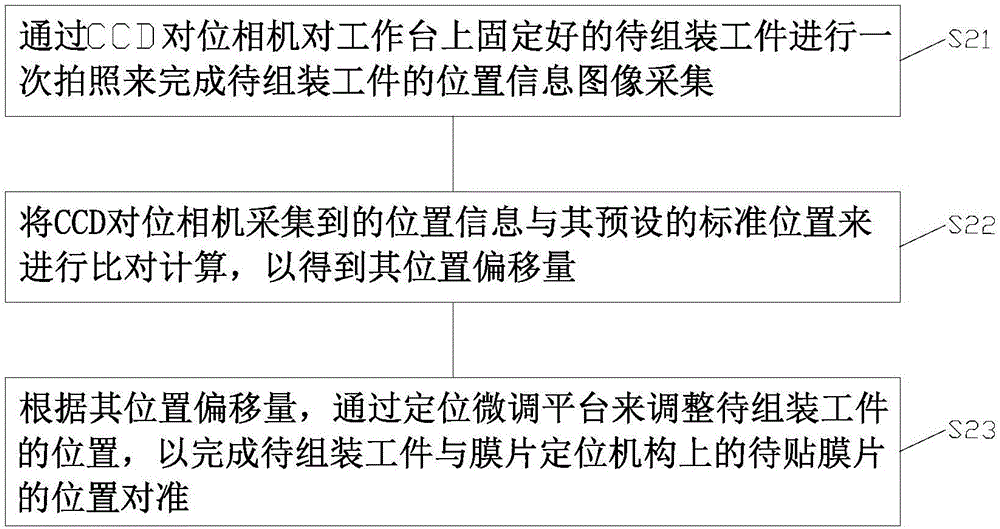

[0045] Embodiment two: if figure 2 As shown, the present embodiment provides a backlight CCD film sticking process, including a diaphragm discharging process, a diaphragm alignment process, and a diaphragm bonding process, wherein the diaphragm alignment process includes the following steps:

[0046] Step S21: take a photo of the workpiece to be assembled after preliminary positioning on the workbench through the CCD alignment camera to complete the image acquisition of the position information of the workpiece to be assembled;

[0047] Step S22: Comparing and calculating the position information collected by the CCD alignment camera with its preset standard position to obtain its position offset;

[0048] Step S23: Adjust the position of the workpiece to be assembled by positioning the fine-tuning platform according to its position offset, so as to complete the alignment between the workpiece to be assembled and the film to be attached on the film positioning mechanism.

[...

Embodiment 3

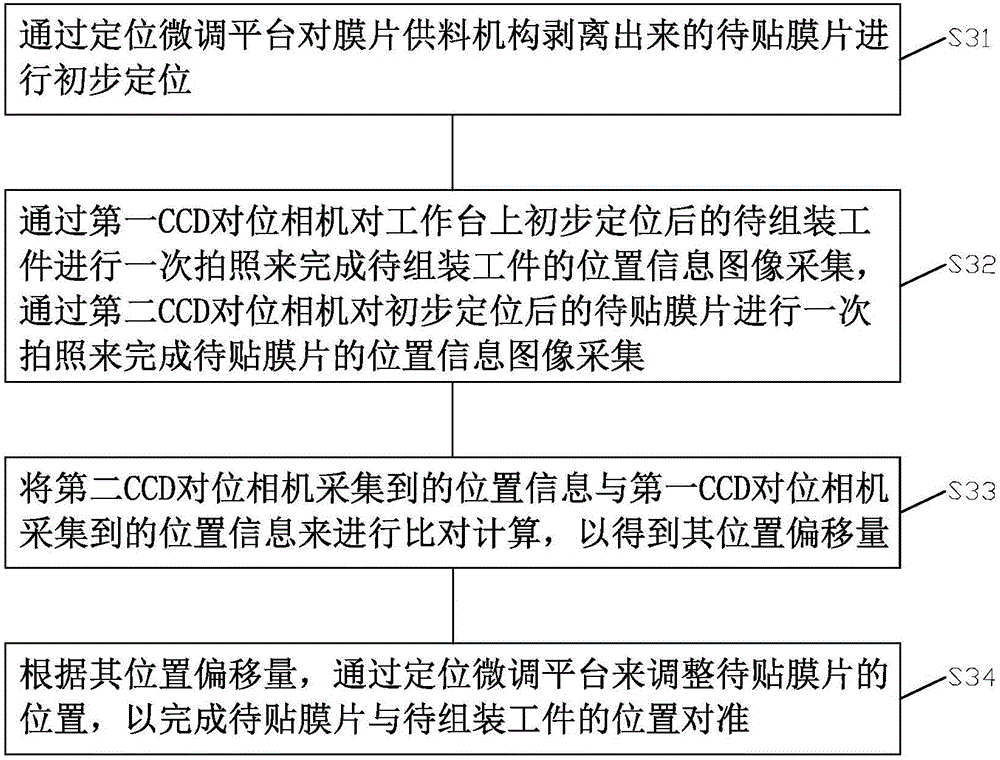

[0051] Embodiment three: as image 3 As shown, the present embodiment provides a backlight CCD film sticking process, including a diaphragm discharging process, a diaphragm alignment process, and a diaphragm bonding process, wherein the diaphragm alignment process includes the following steps:

[0052] Step S31: Preliminary positioning of the film to be pasted by the film feeding mechanism through the positioning fine-tuning platform;

[0053] Step S32: Use the first CCD alignment camera to take a photo of the workpiece to be assembled after preliminary positioning on the workbench to complete the position information image acquisition of the workpiece to be assembled, and use the second CCD alignment camera to take a photo of the preliminarily positioned workpiece to be attached Take a photo to complete the image acquisition of the position information of the film to be pasted;

[0054] Step S33: Comparing and calculating the position information collected by the second CCD ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com