Pasting method for machine vision-based irregular electronic device

A technology for electronic components and components, which is applied in the direction of assembling printed circuits with electrical components, and can solve the problems of high price, high price, and time-consuming machine adjustment of imported chip mounters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

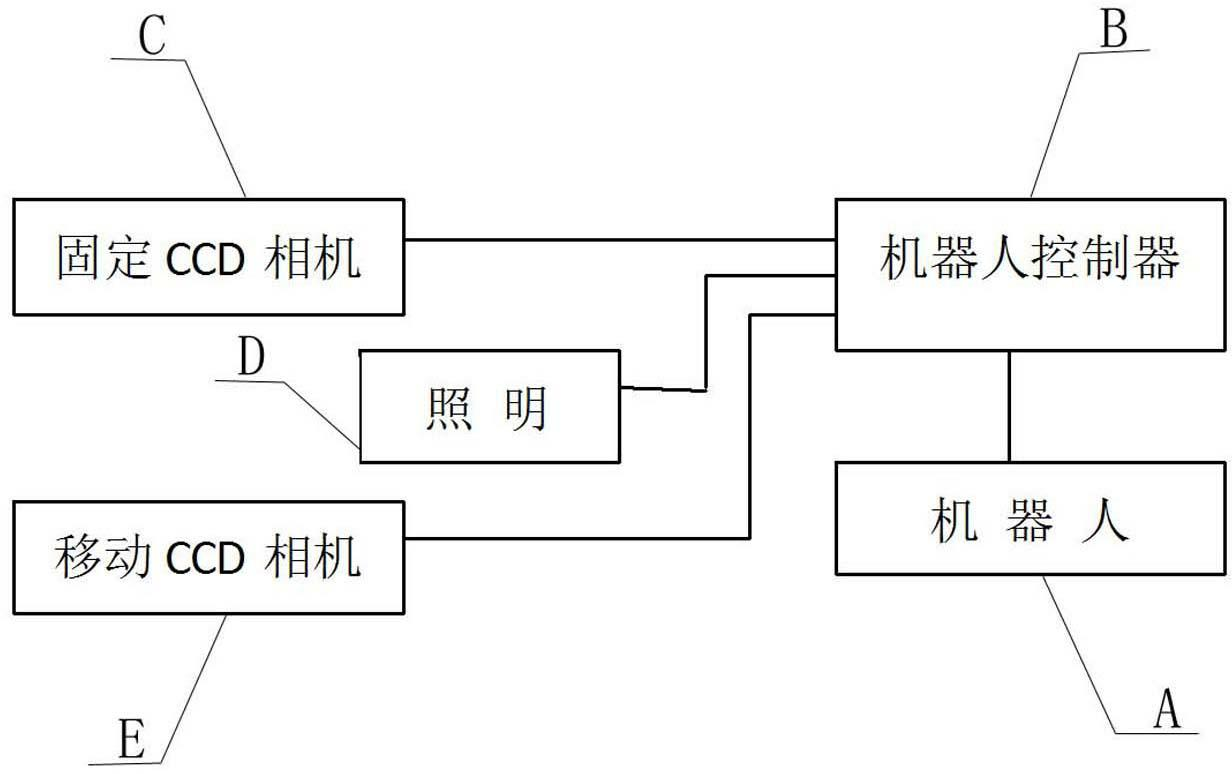

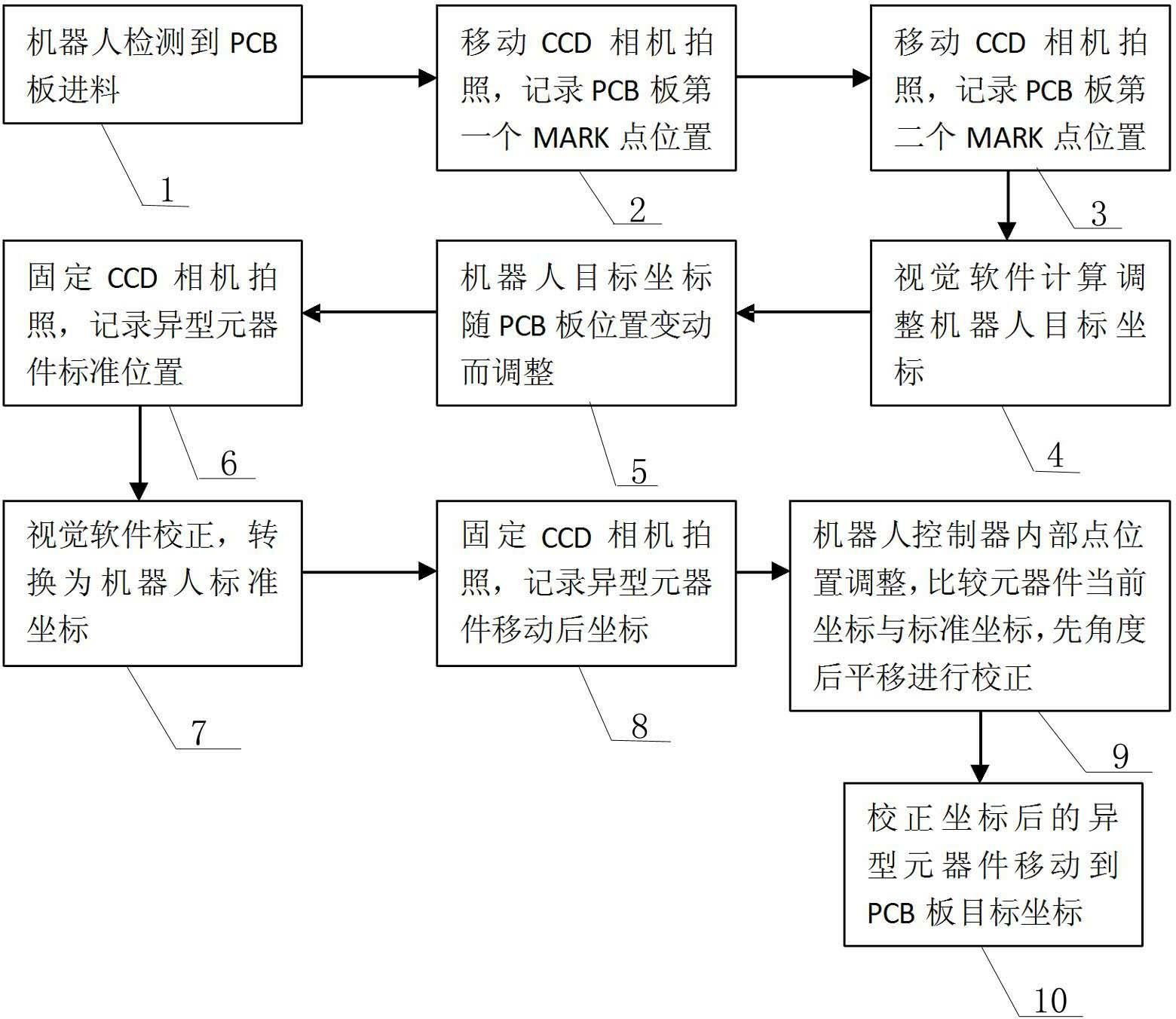

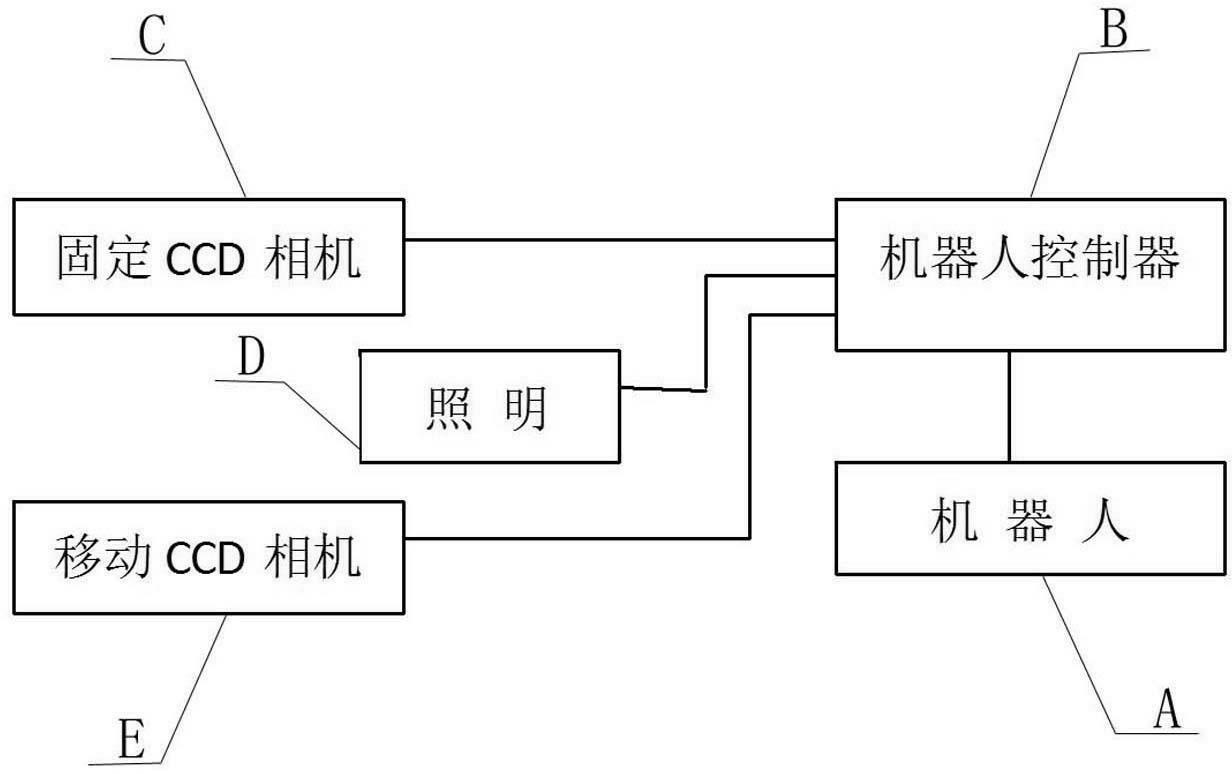

[0009] Such as figure 1 As shown, the placement robot includes a mobile CCD camera, a fixed CCD camera, a robot controller, a robot body and a lighting fixture. The fixed CCD camera is installed in the working range of the manipulator and installed downwards. A mobile CCD camera is installed within the working range of the manipulator. The CCD camera adopts the edge search method, and the special-shaped electronic components can be searched even if they are partly outside the field of view. components. The robot controller has its own vision software, which receives the coordinate values of the mobile CCD camera and the fixed CCD camera about the PCB board and special-shaped electronic components, and transmits the instructions to the robot for execution after correction. The robot body is a 4-axis multi-joint horizontal robot. During the working process of the robot, the deviation between the center value of the R-axis of the robot and the center value of the fixture sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com