Matrix-type surface mounted device

A placement machine and matrix technology, applied in the field of double-head matrix placement machines, can solve the problems of production efficiency limitation and inability to fine-tune the distance, and achieve the effect of improving placement efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

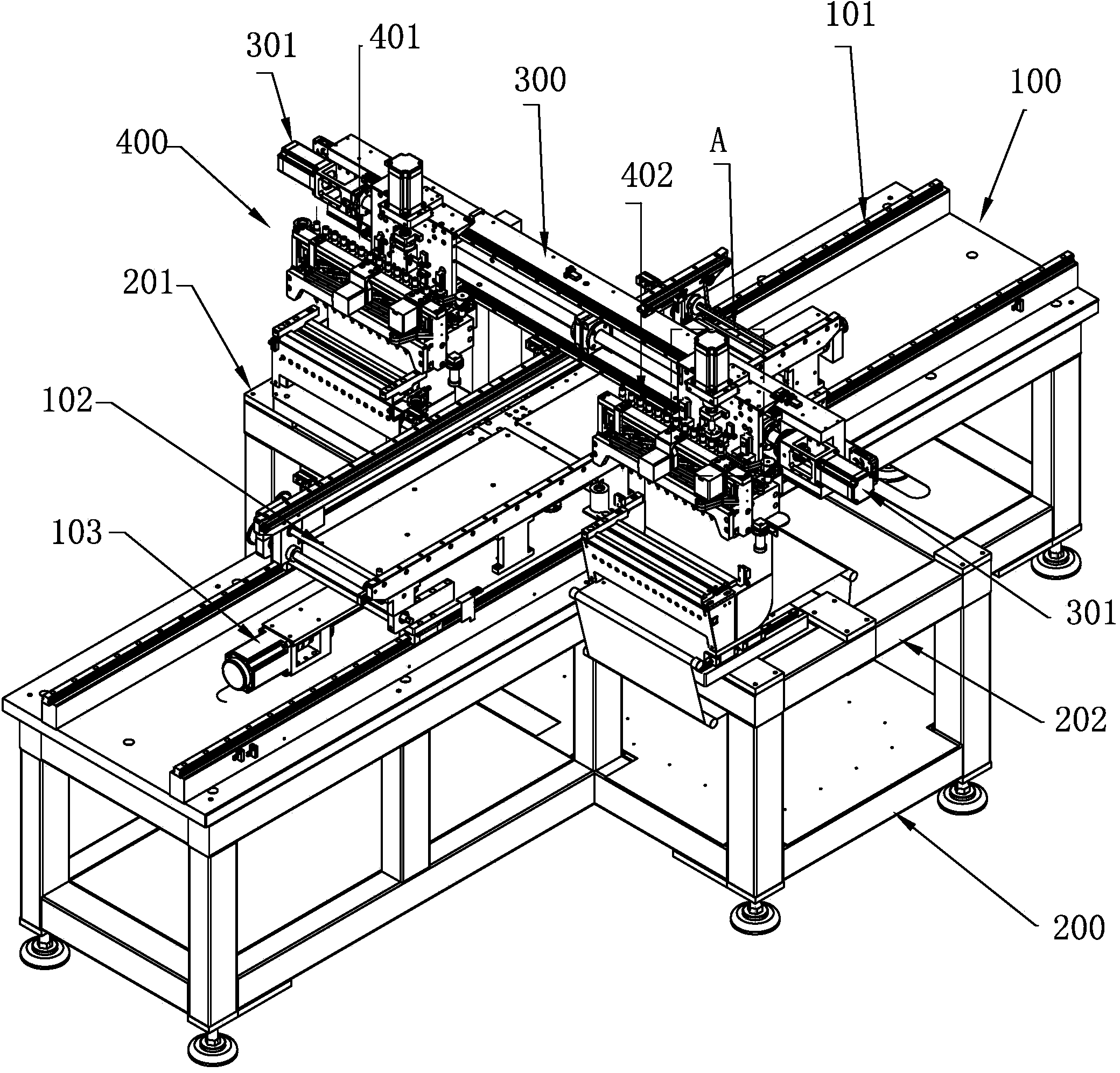

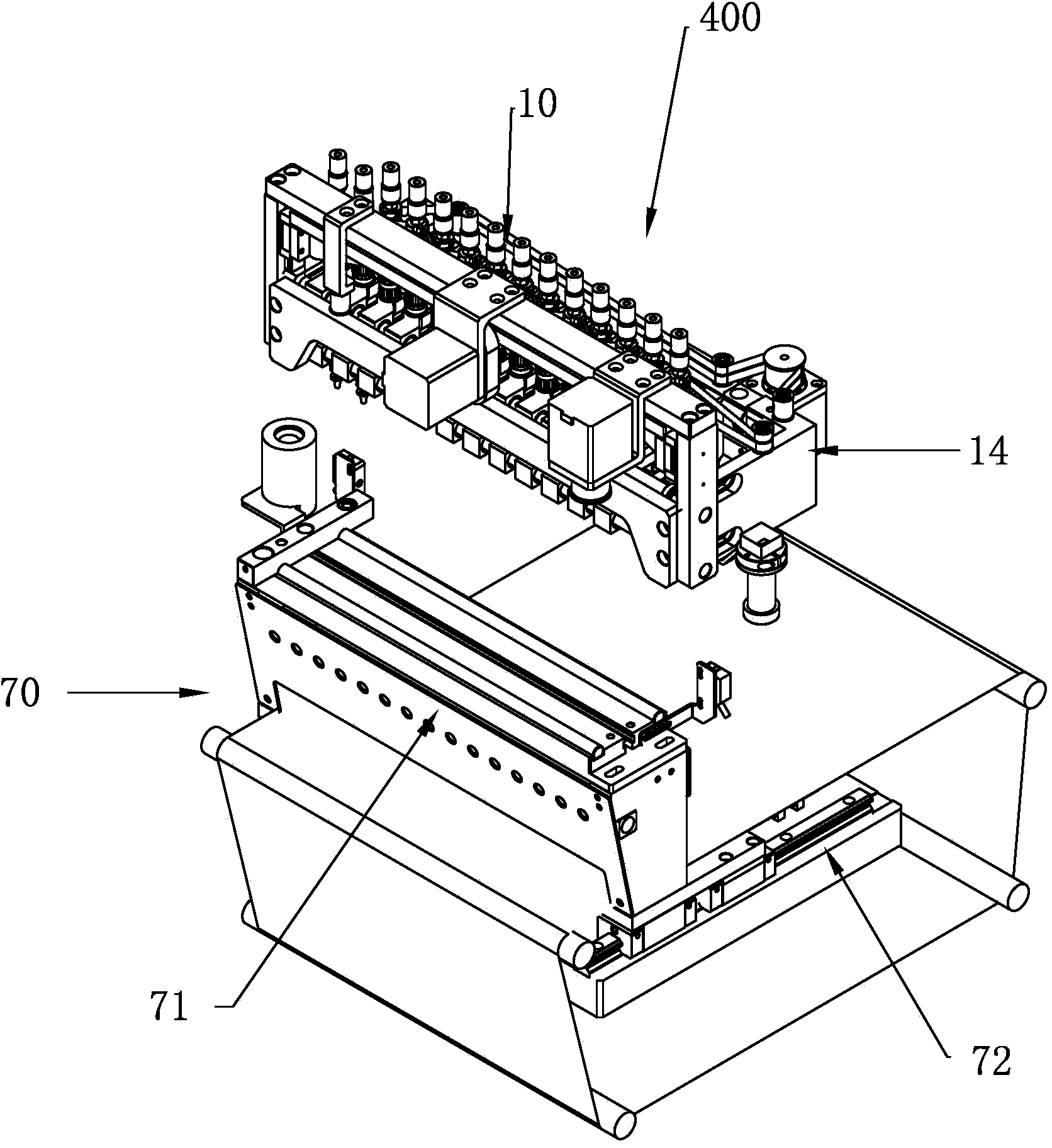

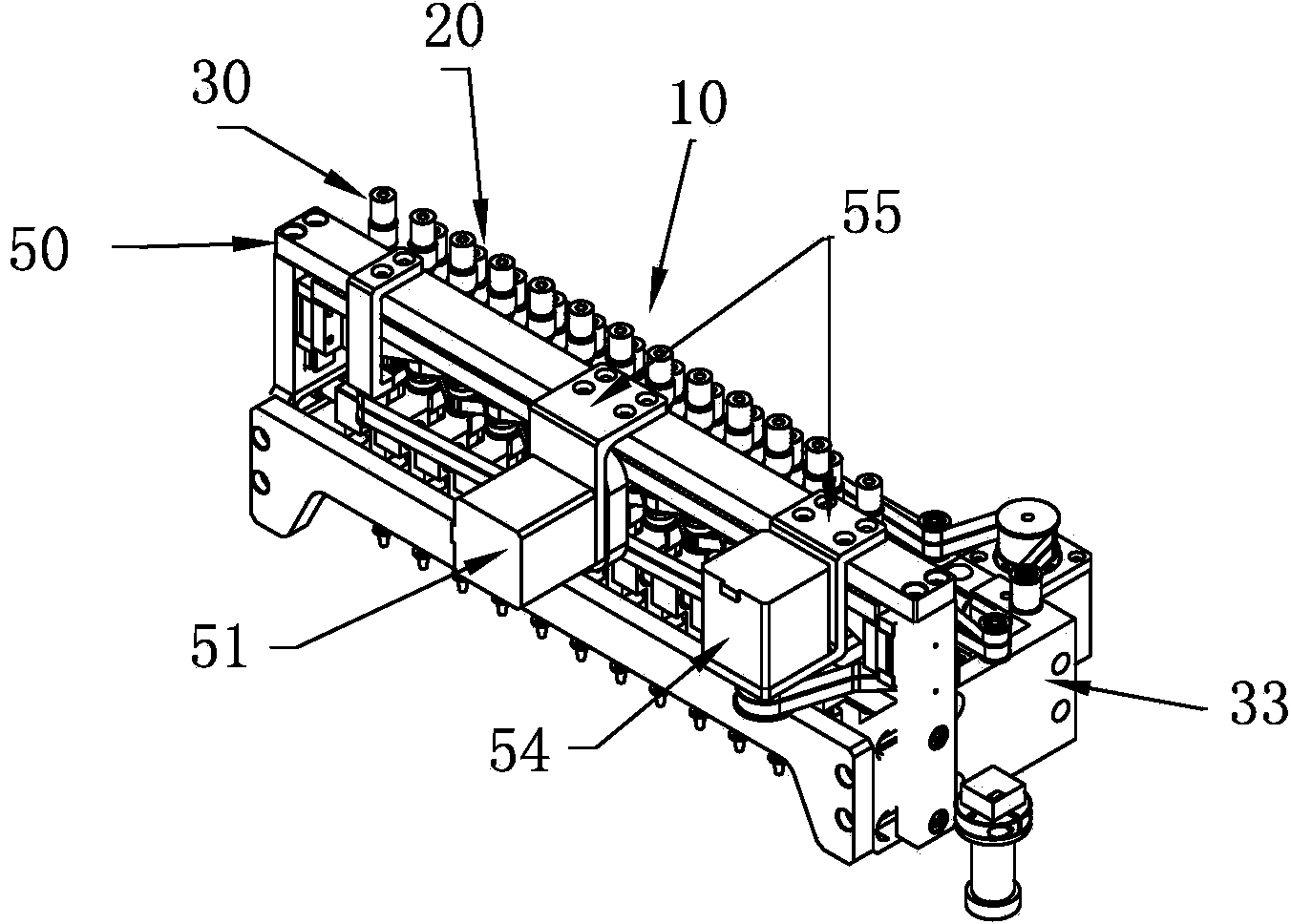

[0032] Such as figure 1 , 2 As shown, the matrix mounter of the present invention is an improvement on the basis of the prior art. It is the same as the existing matrix mounter. It consists of a vertical frame 100, a horizontal frame 200, and a main beam 300, placement machine 400 and control system.

[0033] On the longitudinal frame 100, two longitudinal guide rails 101, a transport guide rail 102 that is placed on the guide rails and can move back and forth along the guide rails, and a transport motor 103 that is arranged on the longitudinal frame 100 and can drive the transport guide rails 102 to move The head of the transportation motor 103 is fixed on one end of the longitudinal frame 100, and its output end is connected to the bottom of the transportation guide rail 102. The transportation motor 103 can be a servo motor or a stepping motor, and the PCB board to be welded is placed On the transport guide rail 102, when the placement machine is working, the PCB board t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com