Preparation method and preparation apparatus of carbonyl sulfide

A carbonyl sulfide and elemental sulfur technology, applied in the directions of carbon oxysulfide, carbon sulfur compounds, etc., can solve the problems of difficulty in ensuring the quality stability of carbonyl sulfide, difficult to obtain high-purity carbonyl sulfide products, and unsuitable for mass preparation, etc. It is easy to achieve large-scale industrial production, reasonable process steps and equipment, and suitable catalyst selection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] In a first aspect, a method for preparing carbonyl sulfide is provided in at least one embodiment, comprising the steps of:

[0056] Pass carbon monoxide and elemental sulfur vapor into a reactor equipped with a metal sulfide catalyst to carry out a synthesis reaction to obtain a mixed gas; the mixed gas is a mixed gas containing carbonyl sulfide;

[0057] After the mixed gas is separated, unreacted elemental sulfur vapor, unreacted carbon monoxide and carbonyl sulfide are obtained, and the unreacted elemental sulfur vapor and unreacted carbon monoxide are returned to the reactor for cyclic reaction;

[0058] The carbonyl sulfide is condensed and collected in a low-temperature collection tank, and then enters a purification system for purification to obtain high-purity carbonyl sulfide.

[0059] The invention uses carbon monoxide and elemental sulfur (sulfur powder) as raw materials for preparation, reacts to synthesize crude products under the action of metal sulfide c...

Embodiment approach

[0099] As a preferred embodiment of the present invention, the process of the process includes:

[0100] a). The metal sulfide catalyst is loaded into the reactor and distributed evenly;

[0101] b). Feed carbon monoxide and elemental sulfur vapor into the reactor under suitable temperature and pressure conditions for reaction, and the mixed gas discharged after the reaction contains unreacted carbon monoxide and elemental sulfur vapor, as well as generated carbonyl sulfide gas;

[0102] c). Pass the mixed gas discharged from the reactor into the gas-solid separator, intercept the unreacted elemental sulfur vapor, and then pass it into the low-temperature collection tank to collect the crude product of carbonyl sulfide, and the raw material carbon monoxide that has not been condensed After being pressurized by the compressor, it returns to the middle reactor to carry out the reaction again;

[0103] d). The amount of carbon monoxide added can be determined according to the pr...

Embodiment 1

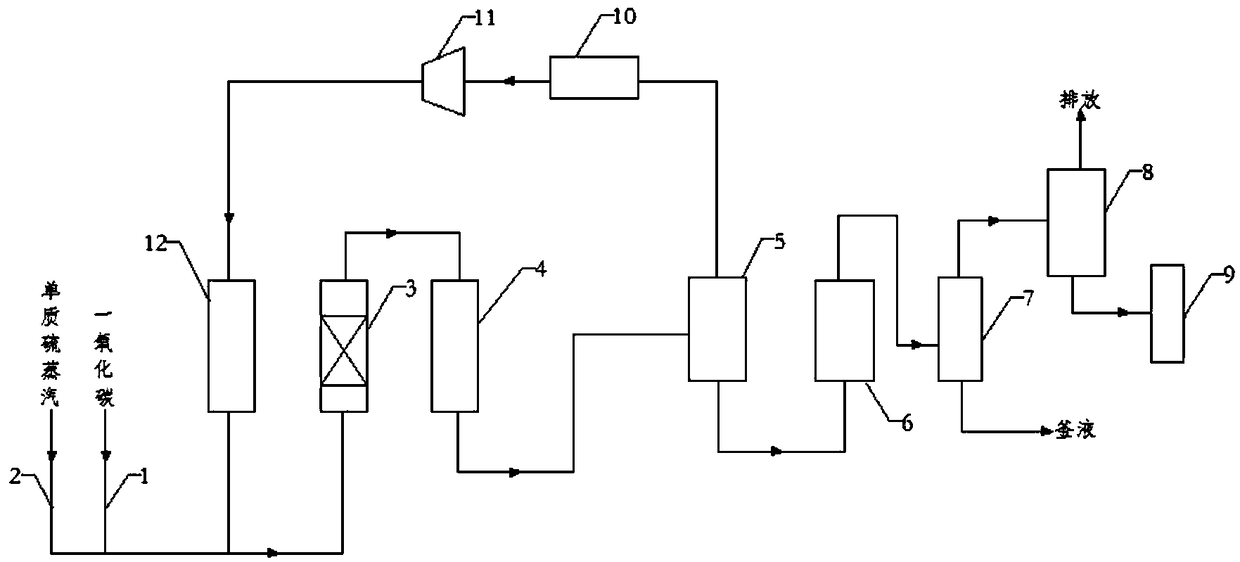

[0127] Such as figure 1 As shown, this embodiment provides a carbonyl sulfide preparation device, including a carbon monoxide raw material supply system, an elemental sulfur raw material supply system, a reactor 3, a separation device, a low-temperature collection tank 5 and a purification system;

[0128] Wherein, the metal sulfide catalyst is filled in the reactor 3; the metal sulfide comprises BaS, FeS, FeS 2 or CaSO 4 at least one of them; the loading volume of the metal sulfide is 2 / 3 to 4 / 5 of the volume of the reactor 3; the material of the reactor 3 includes at least one of monel, inconel and acid-resistant nickel alloy kind.

[0129] The separation device includes a gas-solid separator 4; the purification system includes an adsorption dryer 6 and a rectification device; the adsorbent in the adsorption dryer 6 includes 3A molecular sieves and / or mordenite molecular sieves; the rectification device includes at least two series-connected The rectification tower 7 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com