Separation system and sodium salt and potassium salt separation method

A separation system, sodium salt technology, applied in the field of separation system and sodium salt and potassium salt separation, can solve the problem of no separation, etc., and achieve the effect of reasonable process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

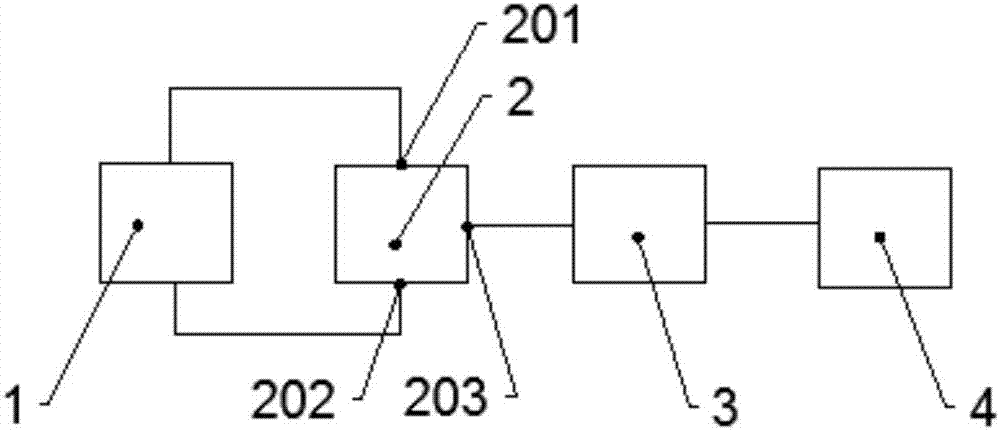

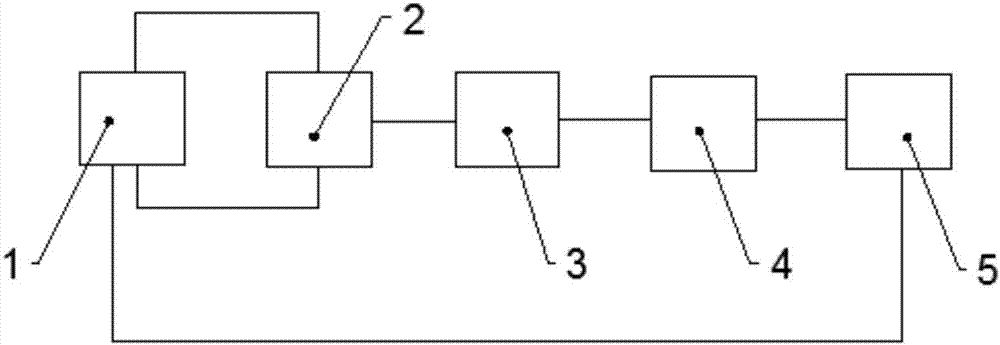

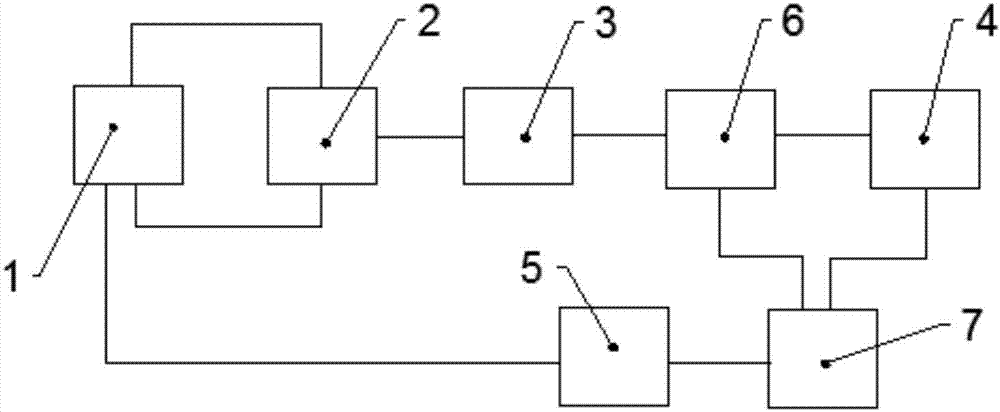

[0039] Such as figure 1 As shown, the present embodiment provides a separation system, including successively connected crystallization separation equipment 1, heat preservation and sedimentation equipment 2, cooling crystallization equipment 3 and centrifugal equipment 4;

[0040] The heat preservation and settling equipment 2 is provided with a material inlet 201, a first material outlet 202 and a second material outlet 203, and the material inlet 201 and the first material outlet 202 are all connected to the crystallization separation device 1,

[0041] The second discharge port 203 is connected with the cooling crystallization equipment 3 .

[0042] The above-mentioned separation system includes successively connected crystallization separation equipment 1, heat preservation and sedimentation equipment 2, cooling crystallization equipment 3 and centrifugal equipment 4; the solution containing sodium salt and potassium salt first passes through crystallization separation eq...

Embodiment 2

[0057] The present embodiment provides a method for separating sodium salt and potassium salt. The above-mentioned separation system is used to treat the waste water containing sodium salt and potassium salt. The separation method includes the following steps:

[0058] (a) the waste water containing sodium salt and potassium salt flows to the above-mentioned crystallization separation equipment place to carry out the crystallization separation of sodium salt to obtain sodium salt crystal and sodium salt mother liquor;

[0059] (b) The sodium salt mother liquor flows to the above-mentioned heat preservation and sedimentation equipment to obtain the sodium salt magma and the first supernatant, and the sodium salt magma returns to the above-mentioned crystallization and separation equipment through the above-mentioned first discharge port to carry out the crystallization and separation of the sodium salt again ;

[0060] (c) The first supernatant liquid flows to the above-mention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com