Four-line splitting rolling technology for fai 12mm round steel

A four-wire slit rolling and process technology, applied in metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of high ellipticity requirements and difficult adjustment, so as to improve operation rate, output and economic benefits Significantly, the effect of improving hourly output and operating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

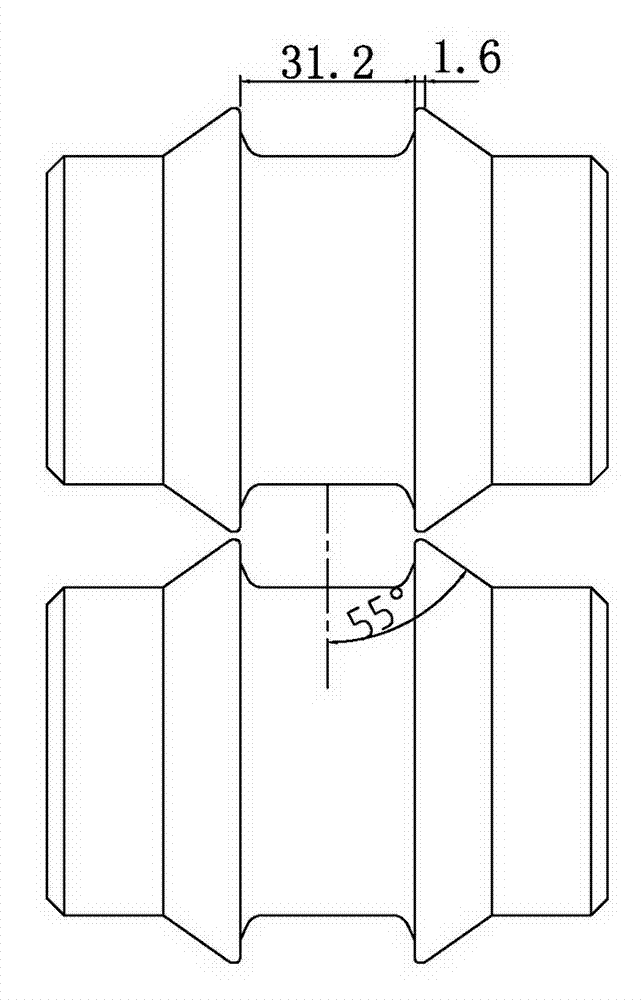

[0029] A four-wire split rolling process for Φ12mm round steel, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, including K5 pre-segmentation pass, K4 pre-segmentation pass and K3 segmentation pass, of which:

[0030] (1) The dimensional tolerance of the section height and width of the rolled piece rolled before K5 pre-cutting is not greater than ±0.2mm;

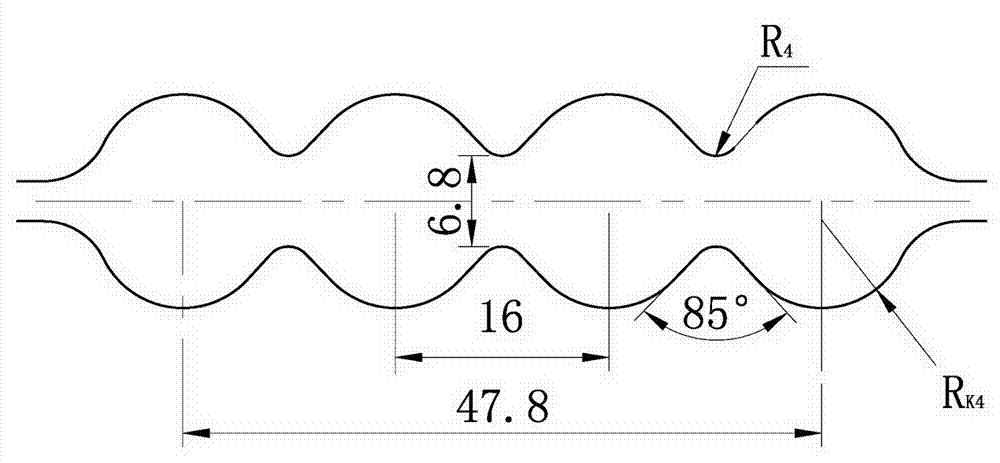

[0031] (2) The rolls used in the K4 pre-slitting pass have four passes arranged side by side. The pass dimensions are as follows: the center distance between the two passes in the middle is 16mm, and the center distance between the two passes on both sides is 47.8mm. Roll wedge angle is 85 o —87 o ; Radius R of wedge top arc 4 1.5-1.8mm, the distance between the wedge tops is 6.8mm, the radius R of the pre-cut hole k4 6.6mm;

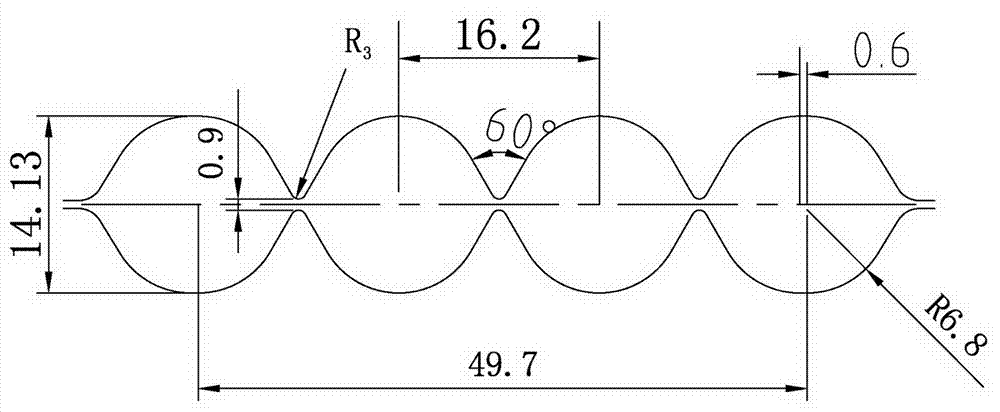

[0032] (3) The pass size of the rolls used in the K3 splitting pass is as follows: the wedge angle of the rolls is 55 o ~60 o ; Radius R of wedge top arc 3 The hei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com