Azithromycin granules and preparation method thereof

A technology of azithromycin and granules, which is applied in the field of chemical pharmacy, can solve the problems that the bitter taste of medicine cannot be effectively masked, and the patient's medication compliance is poor, and achieves the effects of low production cost, high production efficiency and improved taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

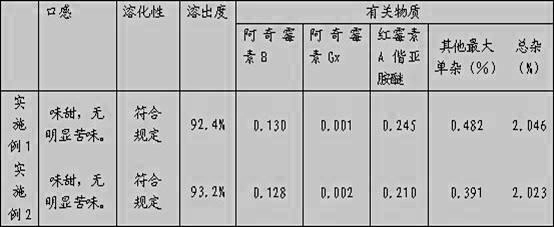

Examples

Embodiment 1

[0033] Embodiment 1: A kind of azithromycin granule (specification 0.1g), its prescription is as follows:

[0034] Azithromycin 100g

[0035] Trisodium Phosphate 20g

[0036] Hydroxypropyl Methyl Cellulose 5g

[0037] Acesulfame K 10g

[0038] Sweet Orange Flavor 10g

[0039] Sucrose 855g

[0040] Appropriate amount of pure water.

[0041] Make 1000 bags.

[0042] Preparation:

[0043] (1) Azithromycin, trisodium phosphate, acesulfame potassium, and sucrose in the prescription were crushed separately and passed through a 100-mesh sieve;

[0044] (2) Hydroxypropyl methylcellulose and aromatics are directly passed through a 100-mesh sieve.

[0045] (3) Weigh the raw and auxiliary materials of the prescribed amount, dry mix them in a mixer for 10 minutes, mix them evenly, use pure water as a wetting agent, granulate with a 16-mesh screen, dry the granules at 55°C for about 3 hours, and granulate , Sieve the particles between 10-60 meshes, and pack them separately.

Embodiment 2

[0046] Embodiment 2: a kind of azithromycin granule (specification 0.125g), its prescription is as follows:

[0047] Azithromycin 125g

[0048] Trisodium Phosphate 20g

[0049] Hydroxypropyl Methyl Cellulose 5g

[0050] Acesulfame K 10g

[0051] Sweet Orange Flavor 10g

[0052] Sucrose 830g

[0053] Appropriate amount of pure water.

[0054] Make 1000 bags.

[0055] Preparation:

[0056] (1) Azithromycin, trisodium phosphate, acesulfame potassium, and sucrose in the prescription were crushed separately and passed through a 100-mesh sieve;

[0057] (2) Hydroxypropyl methylcellulose and aromatics are directly passed through a 100-mesh sieve.

[0058] (3) Weigh the raw and auxiliary materials of the prescribed amount, dry mix them in a mixer for 10 minutes, mix them evenly, use pure water as a wetting agent, granulate with a 16-mesh screen, dry the granules at 55°C for about 3 hours, and granulate , Sieve the particles between 10-60 meshes, and pack them separately.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com