Composite catalyst, preparation method as well as application thereof in reaction of preparing isobutene by dehydrogenating iso-butane

A catalyst and composite technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of shortened catalyst service life, poor catalytic reaction stability, and product side effects Reaction and other problems, to achieve the effects of good permeability, mass transfer and heat transfer performance, not easy to deep dehydrogenation, and high reaction stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

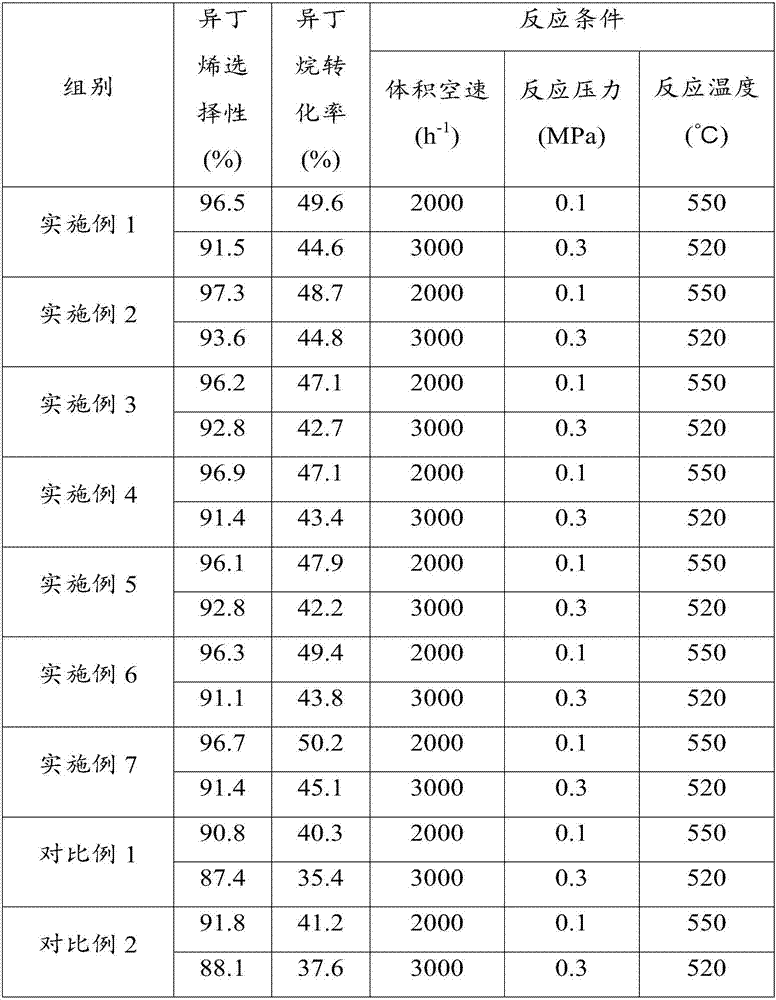

Examples

preparation example Construction

[0048] In the second aspect, the present invention provides a method for preparing a composite catalyst, comprising the following steps: uniformly mixing the supported platinum catalyst, metal microfibers and paper pulp, and then forming a filter cake by papermaking, then drying and oxidizing the filter cake, Sintering in a hydrogen atmosphere, and finally firing in an oxidizing atmosphere to obtain the composite catalyst.

[0049] The preparation method of the above-mentioned composite catalyst has reasonable process steps, simple method, easy-to-obtain raw materials, and controllable structure, which can make the supported platinum catalyst evenly included in the three-dimensional network formed by sintering metal microfibers (the contact of metal microfibers during sintering The metal microfibers are fused together to form a three-dimensional network), and the obtained composite catalyst has a large void ratio, good permeability, mass and heat transfer performance, good low-...

Embodiment 1

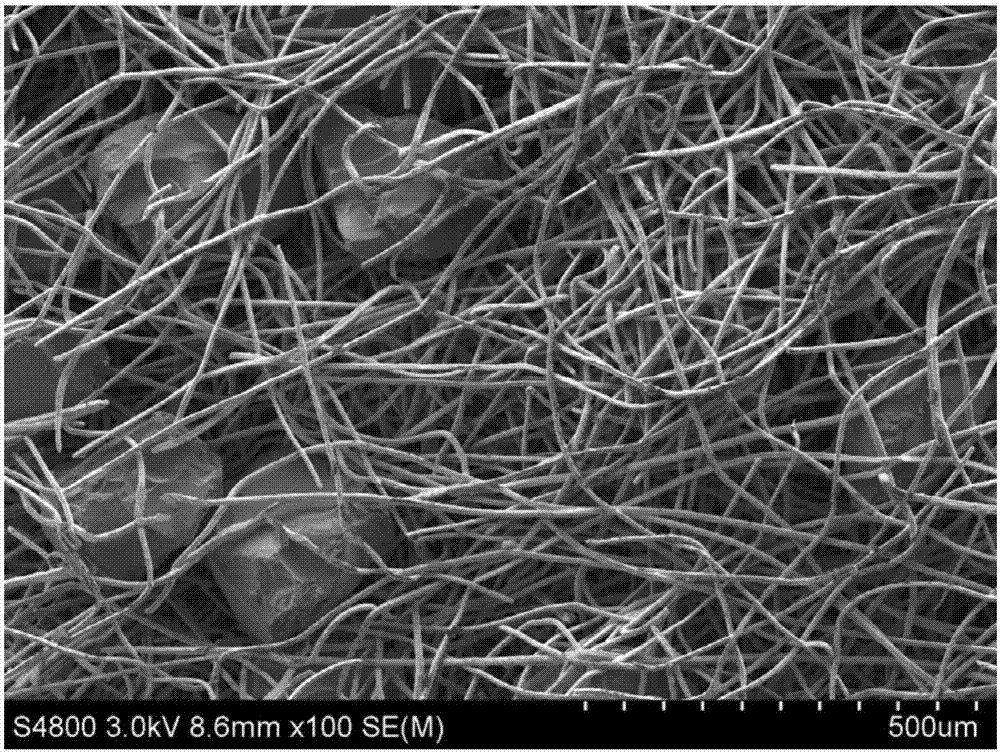

[0061] A kind of composite catalyst mainly is made up of supported platinum catalyst Pt / AlO and nickel microfiber, and its preparation method is:

[0062] Mix 10 g of nickel microfibers with a length of 2-3 mm and a diameter of 8 μm, 5 g of supported platinum catalyst Pt / AlO with a particle diameter of 250-500 microns, 3.3 g of cellulose (filter paper) and 1 L of water, stir evenly, and place on the paper The paper is formed on the forming machine, and the obtained thin-layer filter cake is dried in the air at 110°C, oxidized in the air at 450°C for 1 hour, and then roasted in a hydrogen atmosphere at 900°C for 1 hour to fuse the contact points of the microfibers. Calcined in air at 600°C for 4h. Thus the composite catalyst Pt / AlO-S-Ni was prepared.

[0063] Wherein, the loading amount of platinum in the supported platinum catalyst is 0.5%.

[0064] Composite catalyst Pt / AlO-S-Ni scanning electron microscope (SEM) photo is referred to in embodiment 1 figure 1 .

Embodiment 2

[0066] A kind of composite catalyst mainly is made up of supported platinum catalyst PtSn / AlO and nickel microfiber, and its preparation method is:

[0067] Mix 10g of nickel microfibers with a length of 2-3mm and a diameter of 8μm, 5g of supported platinum catalyst PtSn / AlO with a particle diameter of 250-500μm, 3.3g of cellulose and 1L of water, stir well, and place on a paper former Papermaking molding, the obtained thin-layer filter cake is dried in the air at 110°C, oxidized in the air at 450°C for 1 hour, and then roasted in a hydrogen atmosphere at 900°C for 1 hour to fuse the contact points of the microfibers, and finally in the air Calcined at 600°C for 4h. Thus the composite catalyst PtSn / AlO-S-Ni was prepared.

[0068] Wherein, the loading amount of platinum in the supported platinum catalyst is 0.5%, and the loading amount of tin is 3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com