Refining method and system for recovery liquid containing cyclopentanone and propylene glycol methyl ether acetate

A propylene glycol methyl ether acetate and cyclopentanone-containing technology, which is applied to the refining process and system field of the recovered liquid in the electronics industry containing cyclopentanone and propylene glycol methyl ether acetate, and can solve the problem that the components are easy to polymerize or decompose, explode, azeotrope And the relative volatility is small, the composition of the recovered liquid is complex, etc., to achieve the effect of safe and reliable production process, reducing the probability of polymerization, reducing corrosion and clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

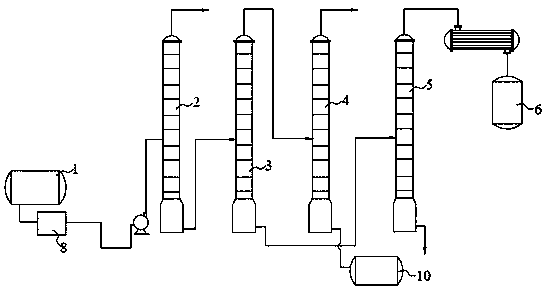

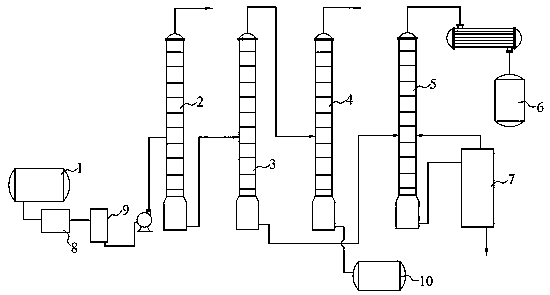

[0036] Such as figure 1 Shown, the refining system that contains cyclopentanone and propylene glycol methyl ether acetate recovery liquid of embodiment 1 comprises pretreatment still 1, the first rectification tower 2, the second rectification tower 3, the third rectification tower 4 and The fourth rectification tower 5;

[0037] The outlet of the pretreatment still 1 is communicated with the first rectification tower 2, and the liquid phase outlet at the bottom of the first rectification tower 2 is communicated with the feed inlet of the second rectification tower 3;

[0038] The top gas phase outlet of the second rectification tower 3 is communicated with the feed inlet of the third rectification tower 4, and the outlet at the bottom of the third rectification tower 4 is communicated with the cyclopentanone receiving tank 10;

[0039] The liquid phase outlet at the bottom of the second rectifying tower 3 communicates with the feed port of the fourth rectifying tower 5, and ...

Embodiment 2

[0042] Such as figure 2As shown, embodiment 2 also comprises evaporator 7, and the feed port of evaporator 7 is communicated with the outlet of heavy component at the bottom of the fourth rectification tower 5, and the gas phase outlet of evaporator 7 is connected with the outlet of the fourth rectification tower 5. The feed port is connected.

[0043] A liquid filter 8 and a preheater 9 are connected between the discharge port of the pretreatment tank 1 and the feed port of the first rectification tower 2 .

Embodiment 3

[0045] The raw material pH value of embodiment 3 is 5.5, light black liquid, and composition is as shown in the following table:

[0046] components

Content % (weight percent)

Low boiling point organic solvents such as acetone

10

water

1.2

50

Propylene glycol methyl ether acetate

35

Resin and metal impurities

3.8

[0047] The first, the second, the third and the fourth in embodiment 3 are atmospheric rectification;

[0048] The raw material with a pH value of 5.5 enters the pretreatment kettle, adds magnesium hydroxide, stirs and neutralizes to a pH value of 7.0~8.0, and enters the middle part of the first rectification tower;

[0049] Acetone is extracted from the top of the first rectification tower, the temperature at the top of the tower is 56.5±2°C, the temperature at the bottom of the tower is 135~138°C, and the light-recovered liquid is extracted from the bottom of the tower and enters th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Moisture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com