Multistage sewage purification system and sewage purification technology

A sewage purification and multi-stage purification technology, which is applied in water/sewage treatment, oxidized water/sewage treatment, multi-stage water/sewage treatment, etc., can solve the problems of long treatment time, high investment cost, and various equipment, and achieve the investment cost Low cost, reduced transportation costs, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

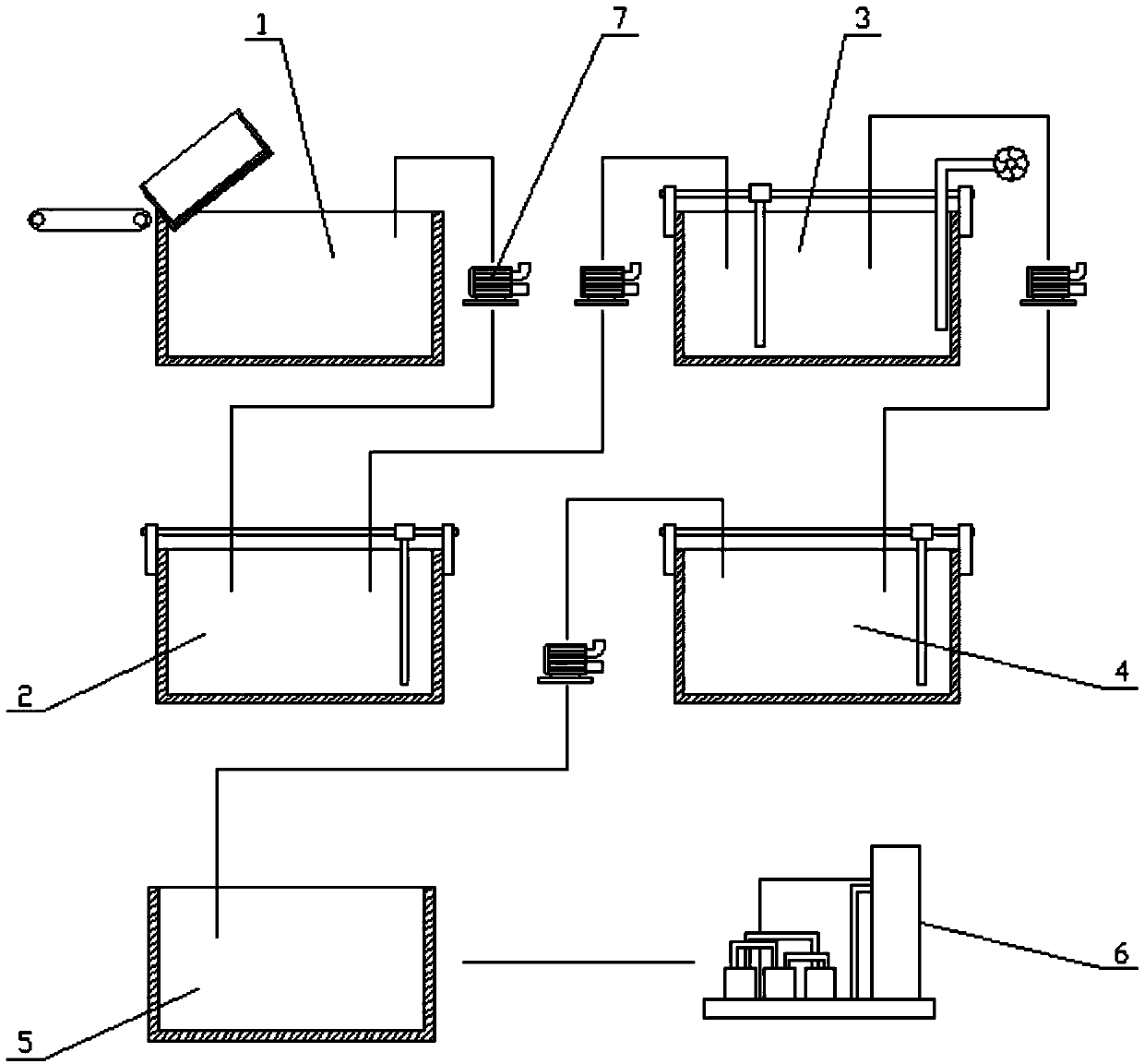

[0034] A sewage purification process, the steps comprising:

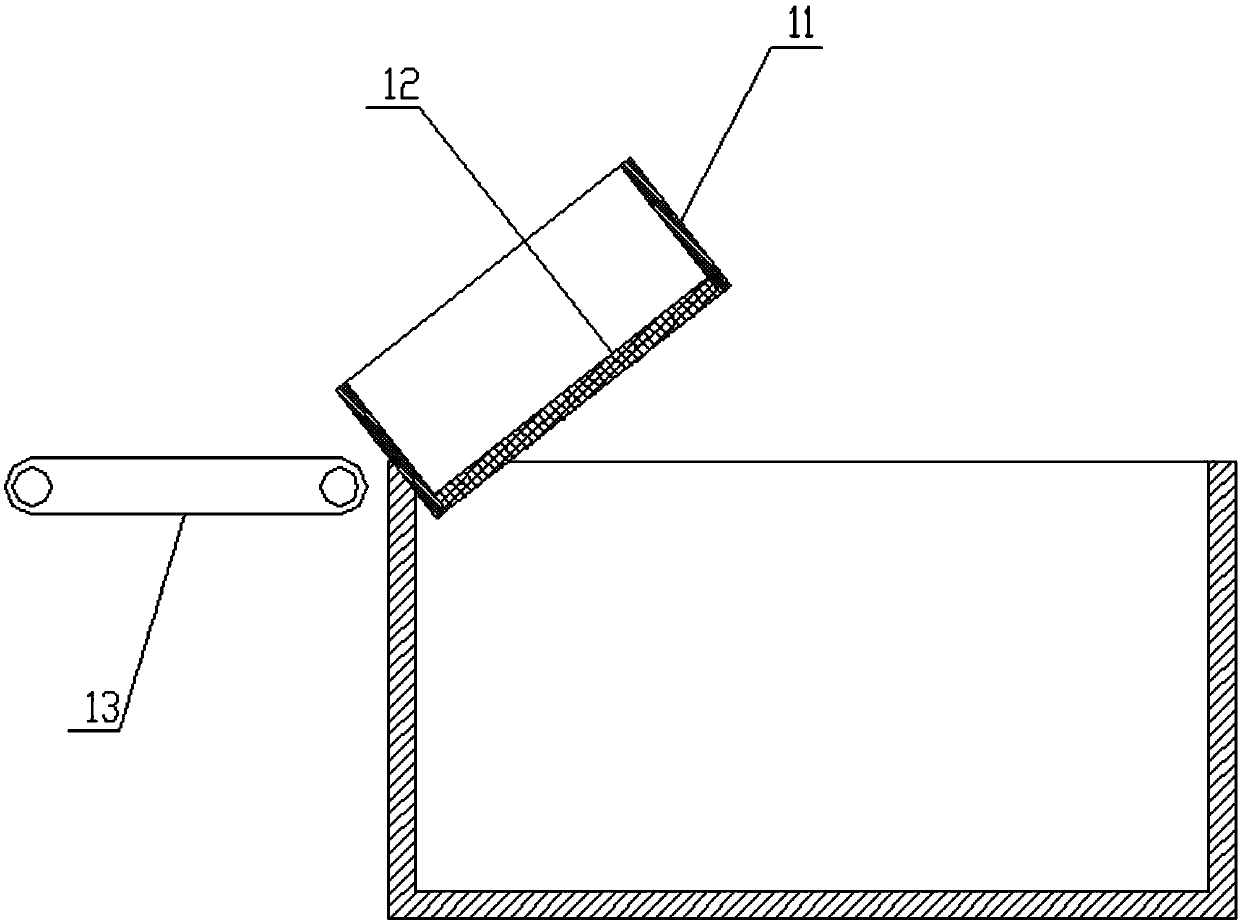

[0035] a. Send the sewage into the sedimentation tank 1 for preliminary sedimentation, and clean up the settled substances at the bottom of the sedimentation tank 1;

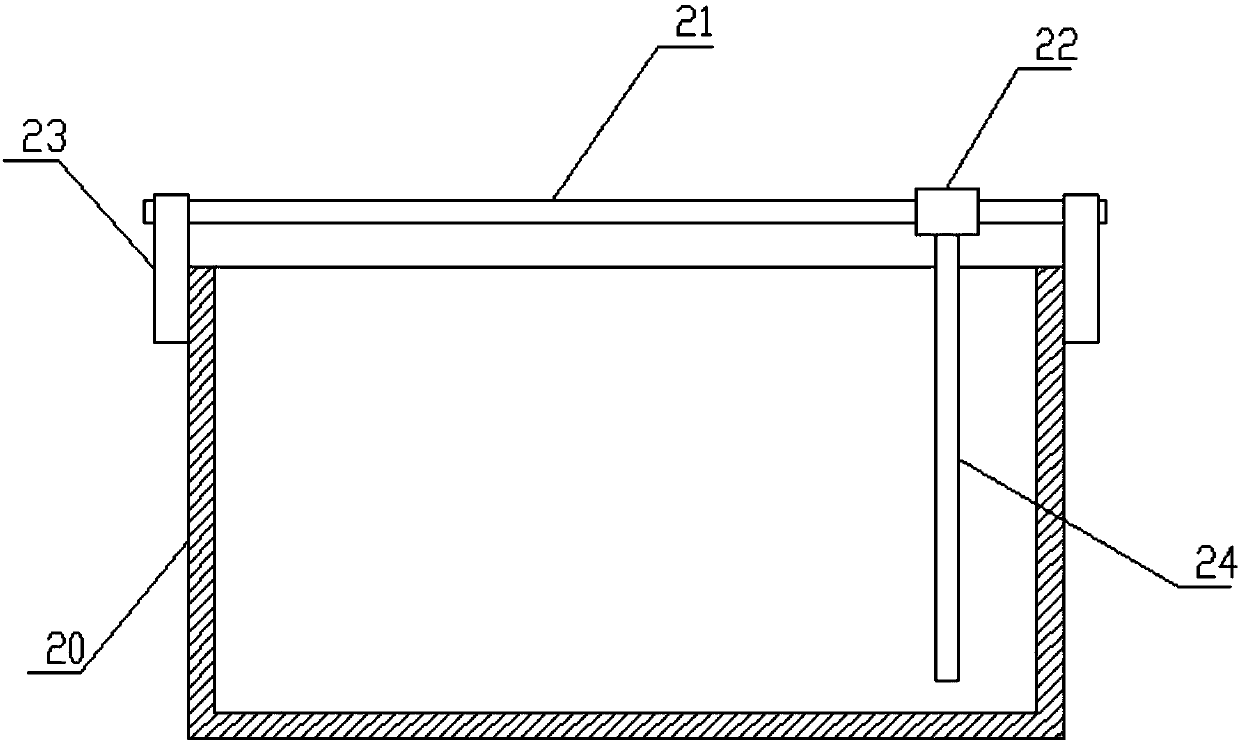

[0036] b. Send the upper layer sewage of the sedimentation tank 1 to the first-level purification tank 2 through the water pump 7, adjust the pH value of the first-level purification tank 2 to 8, stir for 30 minutes, add porous adsorbent while stirring, carry out precipitation, and clean up a The precipitated matter at the bottom of the first-grade sewage purification layer, and the porous adsorbent is washed burnt cinder;

[0037]C, the upper floor sewage of the primary purification pond 2 is sent into the secondary purification pond 3 by the water pump 7, and is exposed to ozone in the secondary purification pond 3 by the air pump 32 and the aeration pipe 31, while aeration, add oxidant, Coagulant and flocculant, then stand still for 24 hours to pr...

Embodiment 2

[0045] A sewage purification process, the steps comprising:

[0046] a. Send the sewage into the sedimentation tank 1 for preliminary sedimentation, and clean up the settled substances at the bottom of the sedimentation tank 1;

[0047] b. Send the upper layer sewage of the sedimentation tank 1 to the primary purification tank 2 through the water pump 7, adjust the pH value of the primary purification tank 2 to 7, stir for 20 minutes, add porous adsorbent while stirring, carry out precipitation, and clean up a The precipitated matter at the bottom of the first-grade sewage purification layer, and the porous adsorbent is washed burnt cinder;

[0048] C, the upper floor sewage of the primary purification pond 2 is sent into the secondary purification pond 3 by the water pump 7, and is exposed to ozone in the secondary purification pond 3 by the air pump 32 and the aeration pipe 31, while aeration, add oxidant, coagulant and flocculant, then stand still for 12 hours to settle, a...

Embodiment 3

[0055] A sewage purification process, the steps comprising:

[0056] a. Send the sewage into the sedimentation tank 1 for preliminary sedimentation, and clean up the settled substances at the bottom of the sedimentation tank 1;

[0057] b. Send the upper layer sewage of the sedimentation tank 1 to the primary purification tank 2 through the water pump 7, adjust the pH value of the primary purification tank 2 to 7.5, stir for 25 minutes, add porous adsorbent while stirring, carry out precipitation, and clean up a The precipitated matter at the bottom of the first-grade sewage purification layer, and the porous adsorbent is washed burnt cinder;

[0058] C, the upper floor sewage of the primary purification pond 2 is sent into the secondary purification pond 3 by the water pump 7, and is exposed to ozone in the secondary purification pond 3 by the air pump 32 and the aeration pipe 31, while aeration, add oxidant, coagulant and flocculant, and then stand still for 18 hours to set...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com