Method and system for regulating hydrogen-carbon ratio of Fischer-Tropsch synthesis gas and co-producing hydrogen

A technology of Fischer-Tropsch synthesis and adjustment method, which is applied in the preparation of liquid hydrocarbon mixtures and the petroleum industry, etc. It can solve problems such as the non-optimal state of Fischer-Tropsch reaction, the difficulty of precise hydrogen-carbon ratio, and the restriction of the economic benefits of Fischer-Tropsch devices. , to achieve the effect of simple structure, convenient operation and easy operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to better understand the technical solutions of the present invention, the content of the present invention will be further described below in conjunction with the embodiments, but the content of the present invention is not limited to the following embodiments.

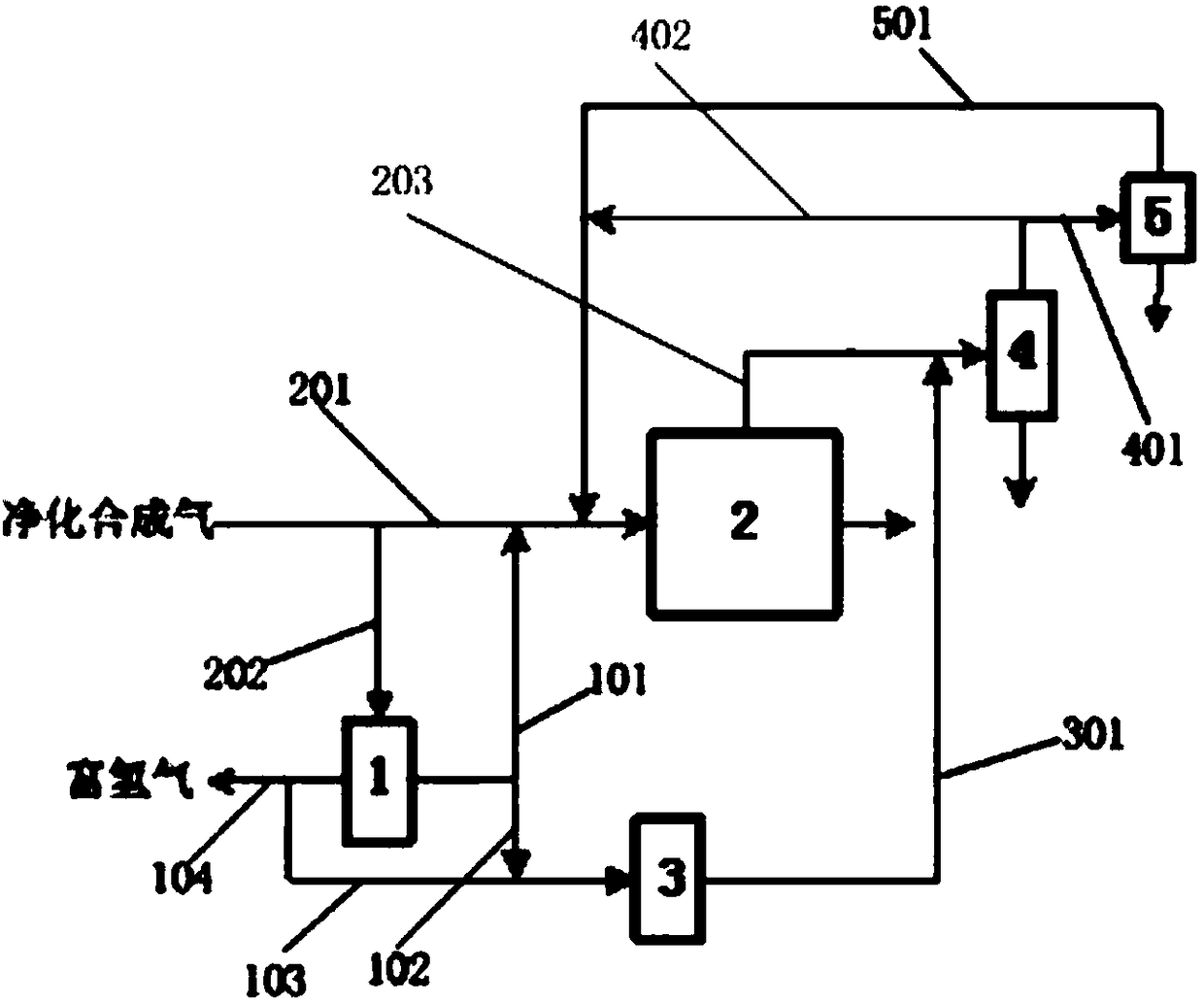

[0051] The present invention provides a hydrogen-carbon ratio adjustment method for Fischer-Tropsch synthesis gas co-production of hydrogen. figure 1 This method is explained.

[0052] The hydrogen-to-carbon ratio adjustment method for the Fischer-Tropsch synthesis gas co-production hydrogen provided by the present invention includes: sending a purified synthesis gas to the Fischer-Tropsch synthesis unit 2, and a purified synthesis gas to the purified synthesis gas separation unit 1, where The two purified syngases can specifically come from the upstream fine desulfurization unit (not shown in the figure). In some preferred embodiments, the total sulfur mass content of the purified synthesis gas is less t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com