Method and system for preparing hydrogen-rich synthesis gas through chemical chain reforming of carbon-based solid fuel

A solid fuel and chemical chain technology, applied in the field of carbon-based solid fuel chemical chain reforming to prepare hydrogen-rich synthesis gas, can solve the problems of difficult product regulation and numerous chemical reactions, and achieve energy saving, avoid reaction rate, and reduce reaction Effect of device and reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0067] The invention mainly includes a pyrolysis reactor, a reforming reactor, a regenerative reactor and its accessory parts as well as a key oxygen carrier.

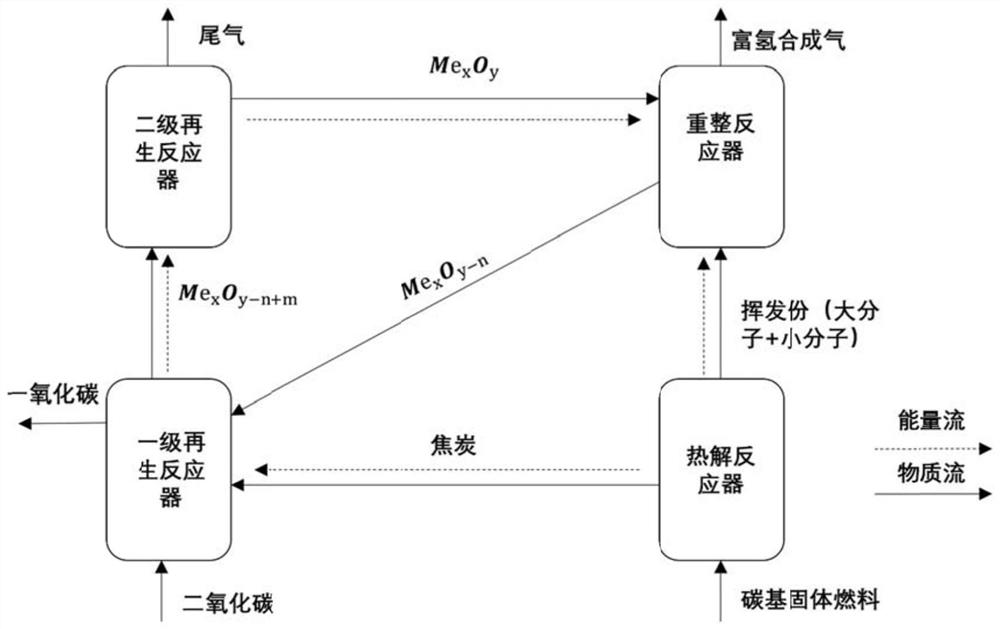

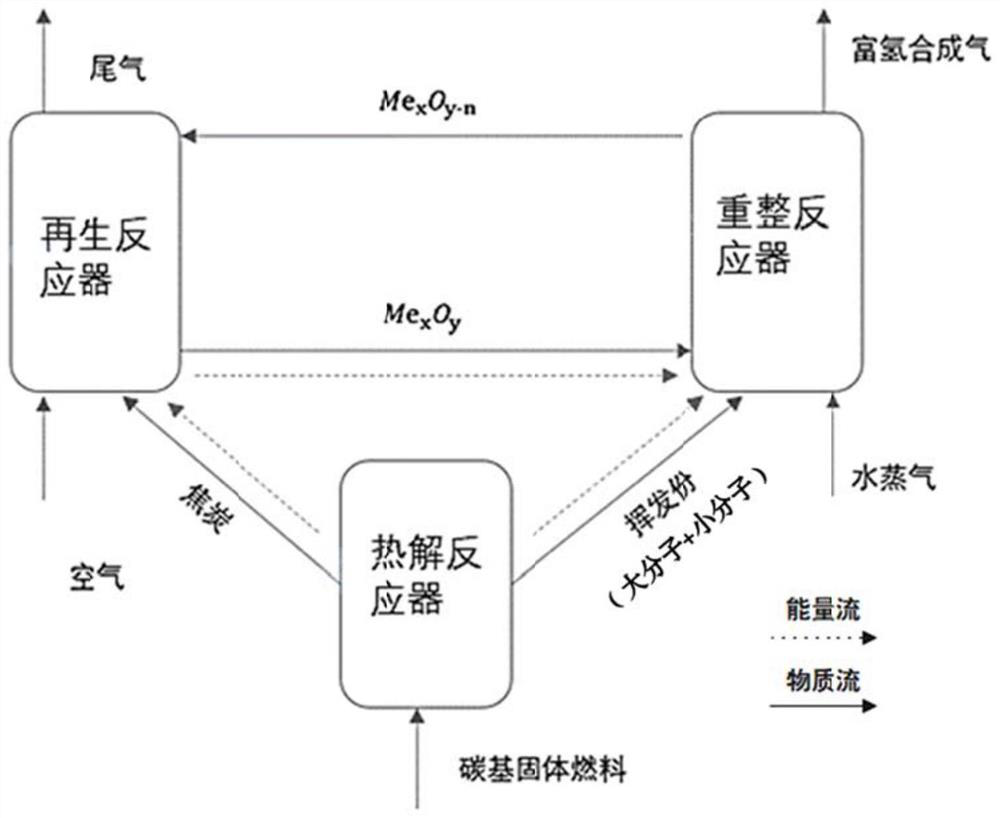

[0068] Such as figure 1 and figure 2 As shown, the carbon-based solid fuel, such as biomass, undergoes pyrolysis reaction in the pyrolysis reactor to generate volatile matter and coke, and the volatile matter mainly contains CH 4 , CO 2 , CO, H 2 Mainly small molecular pyrolysis gas of small molecules and tar of large molecules represented by benzene and toluene.

[0069] The volatile matter enters the reforming reactor, and the coke is sent to the regeneration reactor. Among the volatiles entering the reforming reactor, the large molecular tar is catalytically cracked under the catalytic action of the oxygen carrier to generate small molecular pyrolysis gas. The small molecular pyrolysis gas reacts with the lattice oxygen provided by the oxygen carrier to form H 2 and CO-based hydrogen-rich synthesis gas. The ...

Embodiment 1

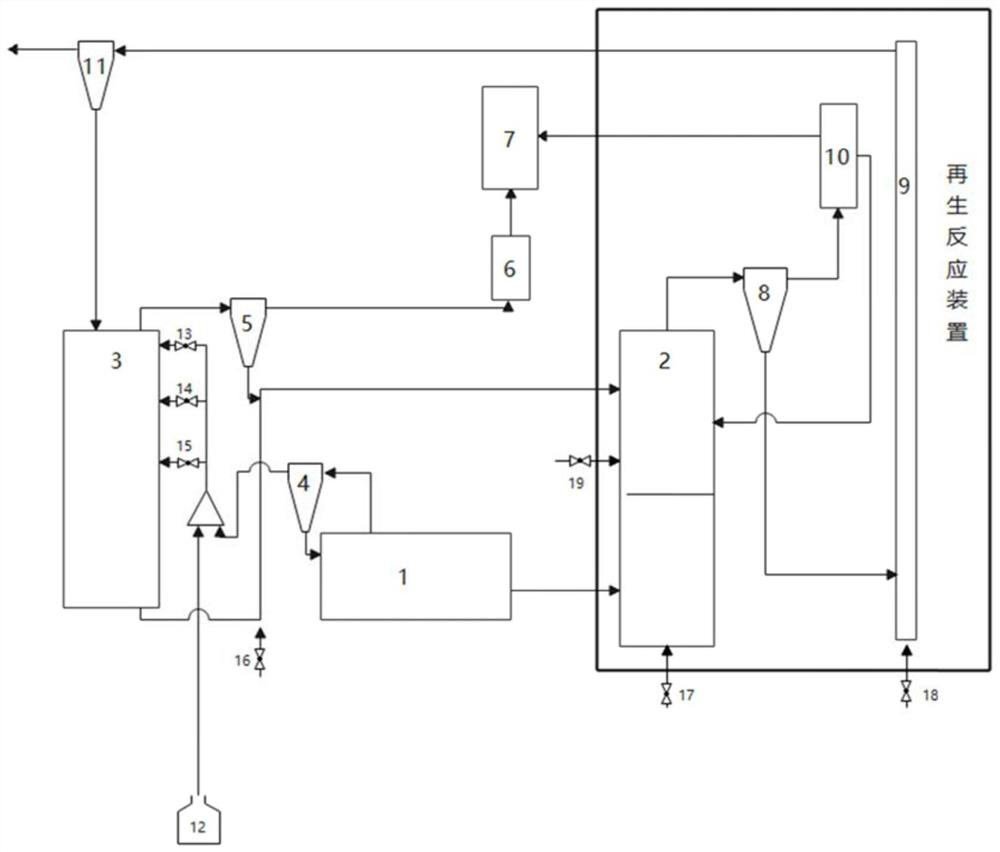

[0073] Such as image 3 As shown, a carbon-based solid fuel chemical chain reforming system for preparing hydrogen-rich synthesis gas according to the present invention includes a pyrolysis reactor 1, a regeneration reaction device, a reforming reactor 3, a scrubbing device 6, a product gas storage tank 7, Steam generator 12 and some cyclone separators, wherein

[0074] The volatile matter outlet of the pyrolysis reactor 1 is connected to the first cyclone separator 4, and then connected with the steam generating device 12 to the volatile matter inlet of the reforming reactor 3, and is divided into three streams, and the coke outlet of the pyrolysis reactor 1 passes through a pipeline Connect the coke inlet of the regenerative reactor 2, wherein the solid particle outlet of the first cyclone separator 4 is connected to the solid particle inlet of the pyrolysis reactor 1;

[0075] The synthesis gas outlet of the reforming reactor 3 is connected to the second cyclone separator ...

Embodiment 2

[0078] The process flow of the chemical chain reformation method is as follows: image 3 shown, including the following steps:

[0079] 1. Pyrolysis.

[0080] Carbon-based solid fuel, such as biomass, enters the pyrolysis reactor 1 via a conveyor belt, and undergoes pyrolysis under an inert atmosphere, such as an argon atmosphere, to generate volatile components and coke. The volatile components include pyrolysis gas and tar , where the pyrolysis gas includes small molecule pyrolysis gas, namely CH 4 , CO 2 , CO and H 2 , tars include benzene, toluene, phenol and naphthalene.

[0081] As the gas is generated, the volatile matter is discharged and enters the cyclone separator 4 from the top of the pyrolysis reactor 1. After the volatile matter passing through the cyclone separator 4 is mixed with water vapor, it is sent to the reforming reactor 3 and separated by a cyclone. The solid particles, including unreacted biomass and coke, separated from reactor 4 are returned to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com