Self-centering buckling-restrained brace beam-column joint

A technology of anti-buckling braces and beam-column joints, applied in the direction of earthquake resistance, building components, buildings, etc., can solve the problems of joints that are prone to brittle failure, unsuitable for continued use, and affect the function of the structure, so as to extend the service life, Rotation constraints reduce and eliminate the effect of residual deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

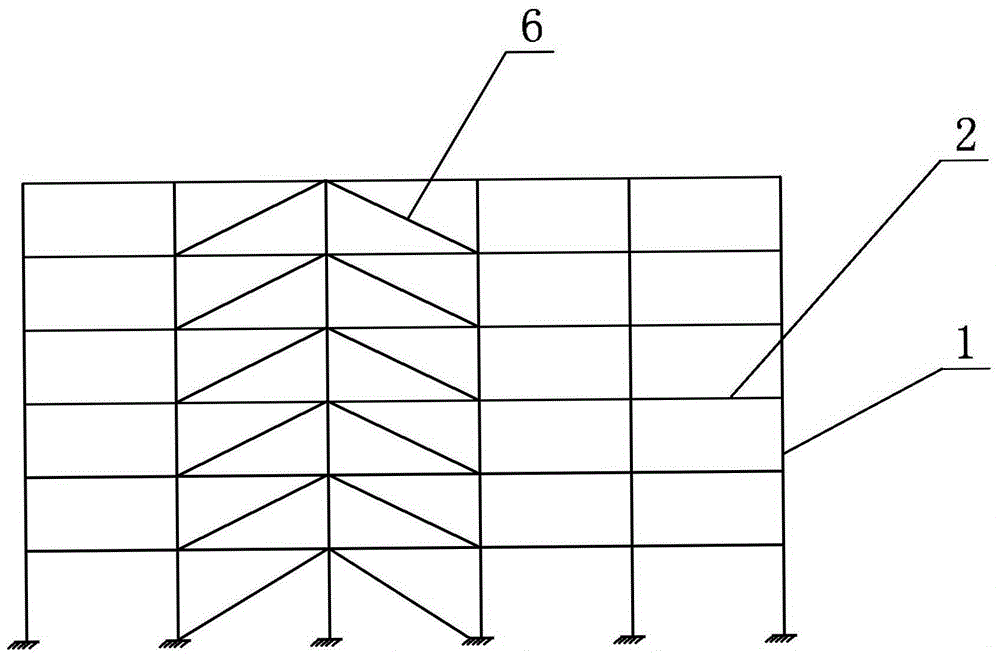

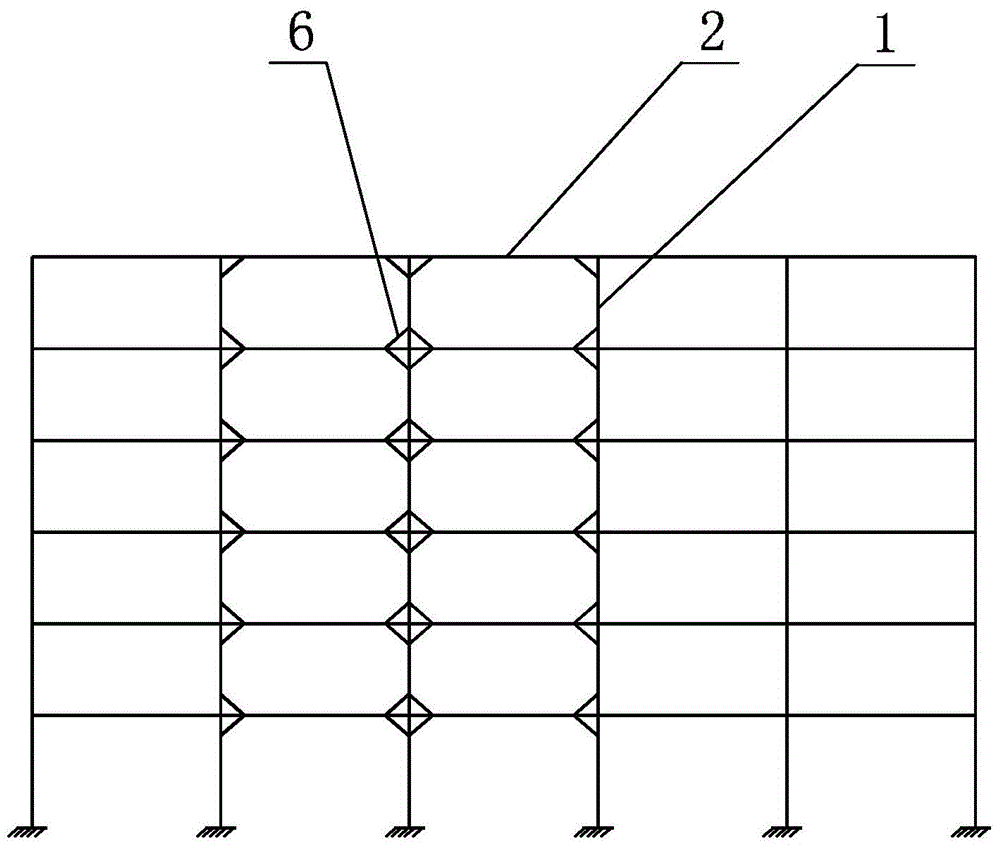

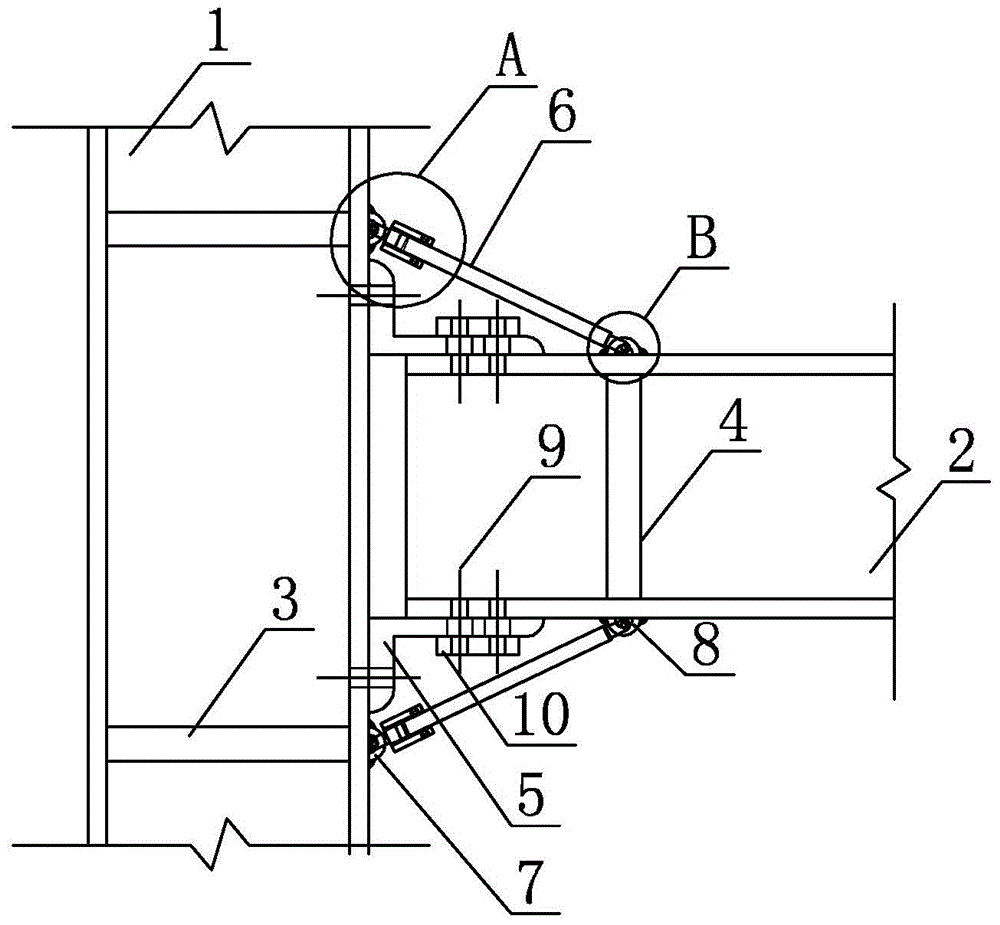

[0027] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 To illustrate this embodiment, this embodiment includes a column 1, a beam 2, two connecting plates 5, two self-resetting buckling-resistant support members 6, a plurality of bolts 9, a plurality of column stiffeners 3 and a plurality of beam stiffeners 4, A gap is set between the column 1 and the beam 2, a plurality of column stiffeners 3 are distributed on the column 1 along the length direction of the column 1, and a plurality of beam stiffeners 4 are distributed on the beam 2 along the length direction of the beam 2, two Connecting plates 5 are respectively arranged on the upper end and the lower end of the beam 2, each connecting plate 5 is L-shaped, the vertical plate section of each connecting plate 5 is connected with the column 1 flange by bolts 9, each connecting plate 5 The horizontal plate section and the vertical plate section ar...

specific Embodiment approach 2

[0029] Specific implementation mode two: combination image 3 This embodiment will be described. In this embodiment, the connecting plate 5 is a first angle steel. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0030] Specific implementation mode three: combination Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 and Figure 12 Describe this embodiment, the self-resetting anti-buckling support member 6 in this embodiment includes a square outer sleeve 6-1, a square inner sleeve 6-2, a first end plate 6-5, a second end plate 6-6, a first Convex connecting plate 6-10, second convex connecting plate 6-11, two energy-dissipating inner core plates 6-3, multiple reset ribs 6-4, two connecting plates 6-7 and two pairs of second angle steels 6-8, the first convex connecting plate 6-10 is arranged between two energy-dissipating inner core plates 6-3, and the upper side wall and the lower side wall of the first convex connecting plate 6-10 Each is affixed to an energy-dissipating inner core board 6-3, and each connection plate 6-7 is arranged outside the corresponding energy-dissipating inner core board 6-3 and the two are affixed; the outside of the square outer sleeve 6-1 A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com