Planet carrier for planetary gear set of automatic transmission

A technology of automatic transmission and planetary gear, which is applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below with reference to the accompanying drawings.

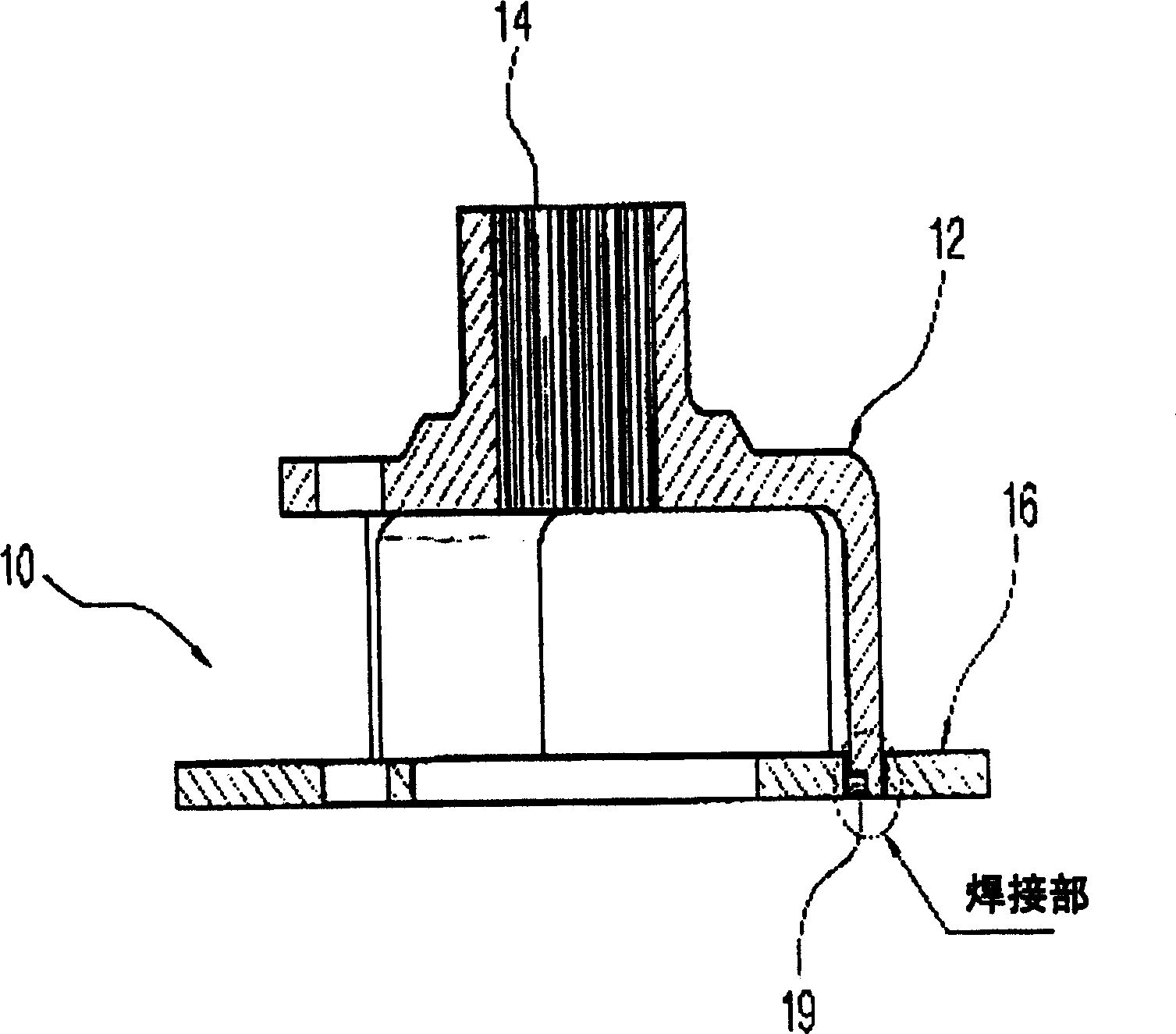

[0032] The present invention relates to a bracket for a planetary gear of an automatic transmission. In the bracket for a planetary gear of an automatic transmission, the hub part is not in the shape of a conventional cup but in the shape of a disk. A bridge is formed by brazing the lower surface of the hub portion to the upper surface of the bridge of the flange portion.

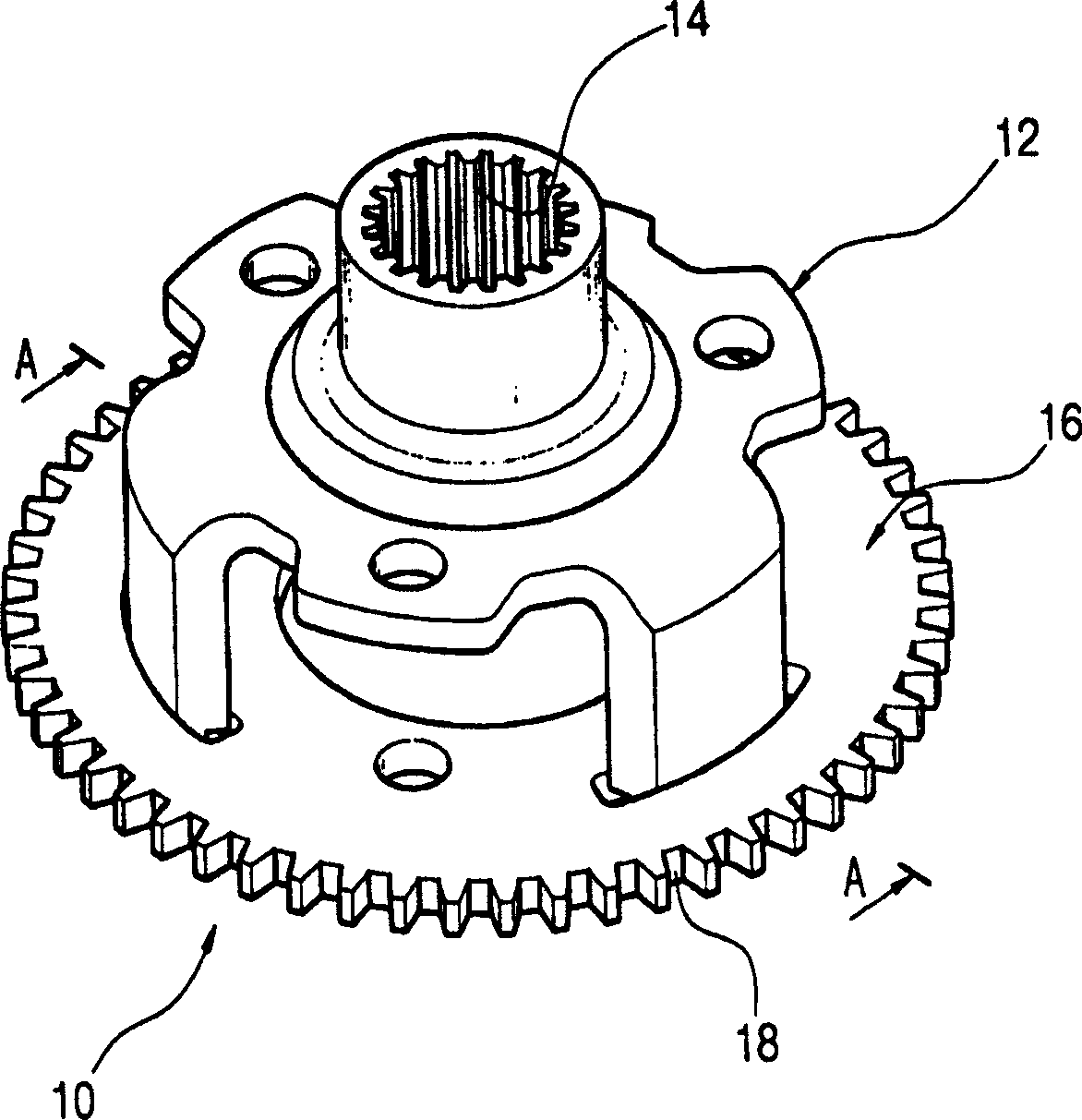

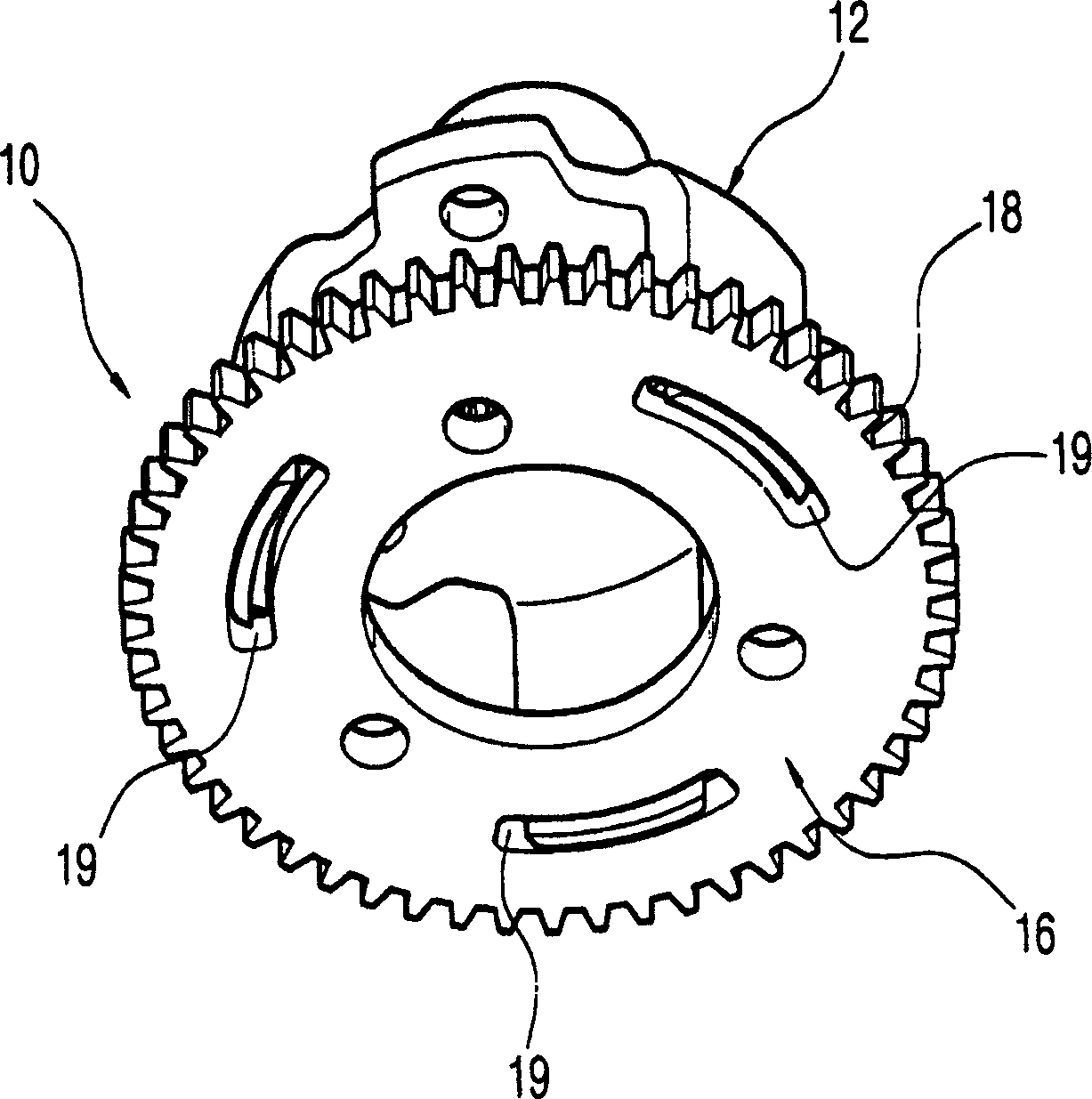

[0033] Figure 4 It is a perspective view showing the planetary gear carrier of the present invention, Figure 5a and Figure 5b It is an exploded perspective view of the carrier for planetary gears of this invention.

[0034] Figure 6 It is a cross-sectional view showing a brazed joint in the planetary gear carrier of the present invention, Figure 7 yes Figure 4 The combined cross-sectional view of the fixing groove and the fixing protrusion of the B-B line.

[0035] The carrier 100 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com