Cellular-structure laminated wood and production method thereof

A production method, honeycomb technology, applied in the direction of wood processing equipment, manufacturing tools, etc., can solve the problems of reduced wood utilization rate, low added value, narrow application range, etc., to improve stability and bonding strength, and eliminate wood strip deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

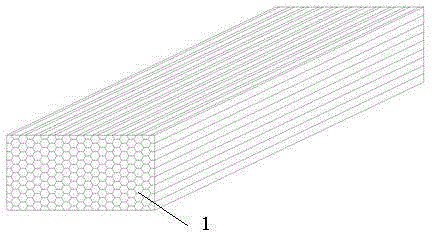

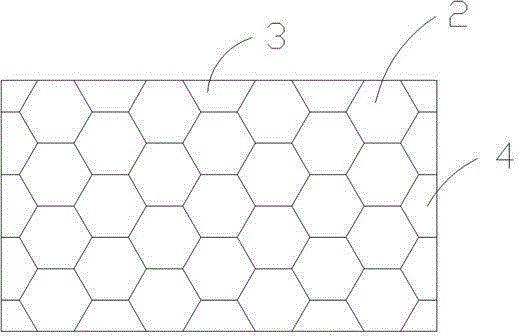

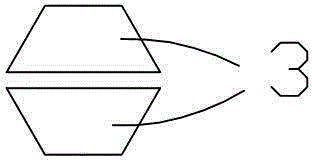

[0026] The glulam 1 with a honeycomb structure is formed by gluing hexagonal wood strips 2 arranged in a honeycomb shape. Hexagonal wood strips are leftover wood cores from plywood production and small-diameter logs with a diameter of less than 6 cm; leftover wood cores from plywood production and small-diameter logs with a diameter of less than 6 cm are planed and sawn into hexagonal wood sticks after drying; Part of the hexagonal strips are cut diagonally to form trapezoidal strips 3 for filling up the gaps in the hexagonal rear edges; Fill up the pentagonal wooden strips 4 of the hexagonal rear edge gaps, the hexagonal wooden strips are glued together in a honeycomb arrangement, the trapezoidal wooden strips 3 and the pentagonal wooden strips 4 The outer side of the glulam with a honeycomb structure, the glulam with a honeycomb structure forms a finished glulam with a square shape.

Embodiment 2

[0028] A method for producing glulam with a honeycomb structure, comprising the following steps:

[0029] (1) Collect the remaining wood cores from plywood production and small-diameter logs with a diameter of less than 6cm;

[0030] (2) Carry out drying treatment, dry the wood core or small-diameter logs according to conventional methods, and control the moisture content at 8-12%;

[0031] (3) Cutting: Cut the dried wood core or small diameter log into a uniform length according to the conventional method;

[0032] (4) Slicing: slice the wood core or small-diameter logs into hexagonal wood strips 2, and part of the hexagonal wood strips are cut diagonally into trapezoidal wood strips for filling the edge gaps after the hexagonal arrangement 3; Some hexagonal wooden strips are bisected along the midpoint of the opposite side to form a pentagonal wooden strip 4 for filling the edge gap after the hexagonal arrangement, which is used to fill the four-sided gap when forming blank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com