Laser welding machine with follow-up and swaging functions

A technology of laser welding machine and laser welding head, which is applied in the direction of laser welding equipment, welding equipment, manufacturing tools, etc., which can solve the problems of poor welding quality, capacitive distance sensor can not be adapted, convex and concave, etc., so as to achieve firm welding quality and eliminate plate Deformation, the effect of ensuring the focus position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

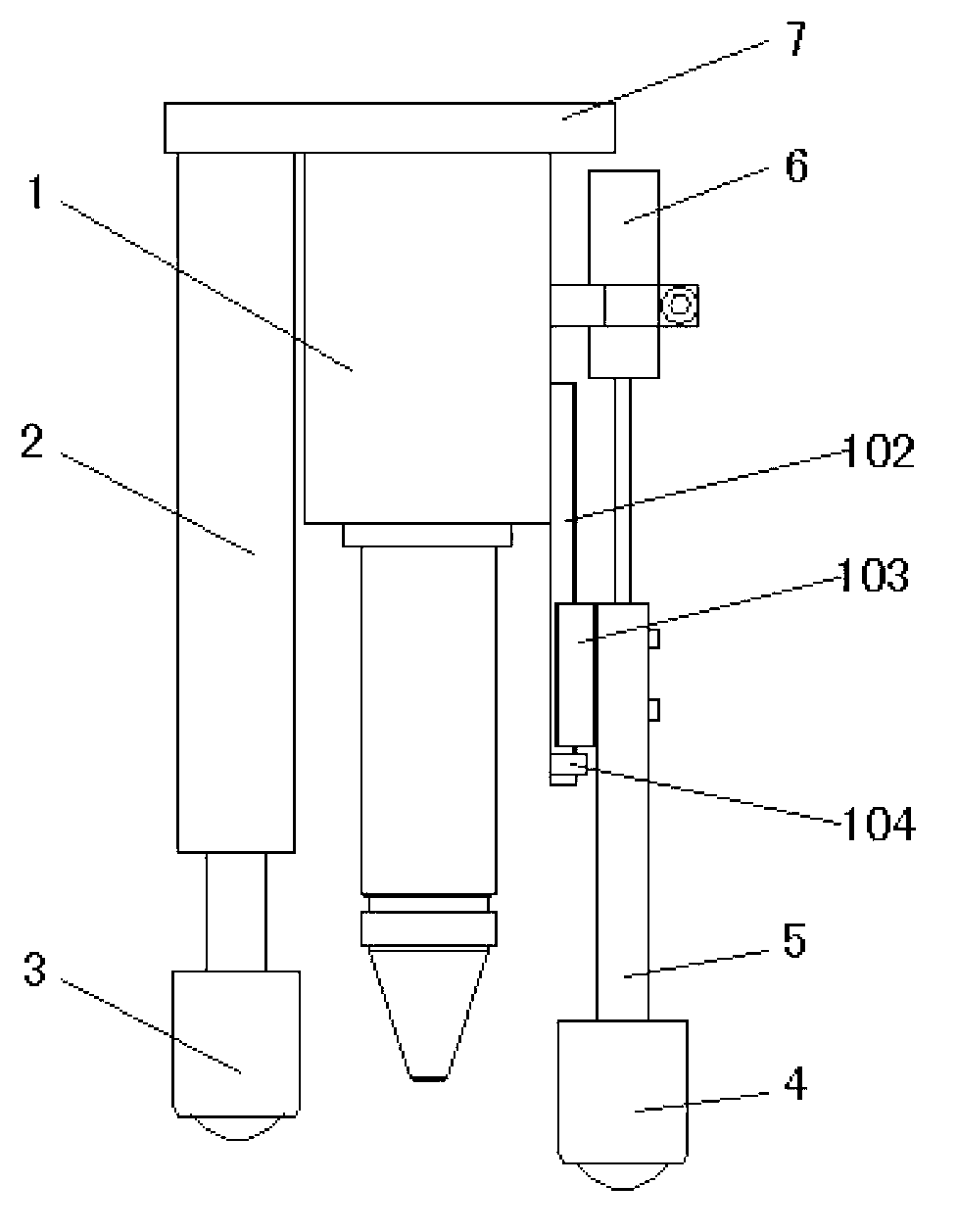

[0011] Embodiment: A laser welding machine with follow-up and pressing functions, including a laser welding head, a kinematic mechanism and a numerical control system, the laser welding head is fixed on the kinematic mechanism, and the kinematic mechanism can drive the laser welding head to move horizontally The laser welding head includes a base 7, a welding head 1, a pressure wheel 3, a follower wheel 4 and a position sensing device 6. Based on the actual use direction, the welding head 1 is fixed on the base 7, the pressing wheel 3 is positioned at the lower end of the base 7, the outer surface of the pressing wheel 3 can be pressed against the surface of the plate to be welded and rolled along its surface, the follower wheel 4 can rotate in the circumferential direction and can slide in the vertical direction to be positioned on the welding head On the side wall of part 1, the outer surface of the follower wheel 4 is in close contact with the surface of the plate to be weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com